Freezing drying machine

A freeze dryer and refrigeration unit technology, applied in the field of freeze dryers, can solve the problems of large gaps between cold plate racks, high energy consumption, cumbersome operations, etc., and achieve increased contact area, heat radiation resistance, and more collisions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

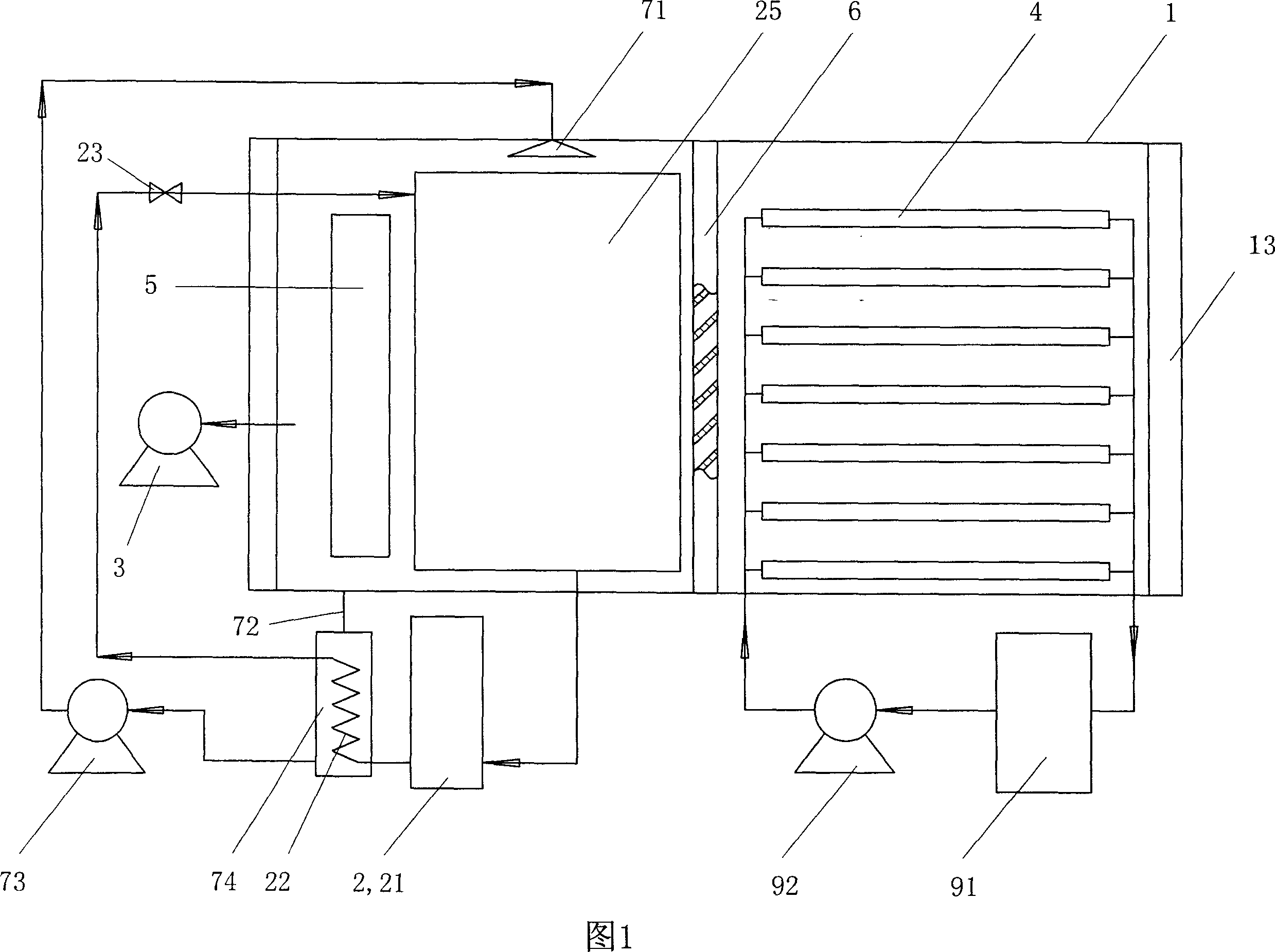

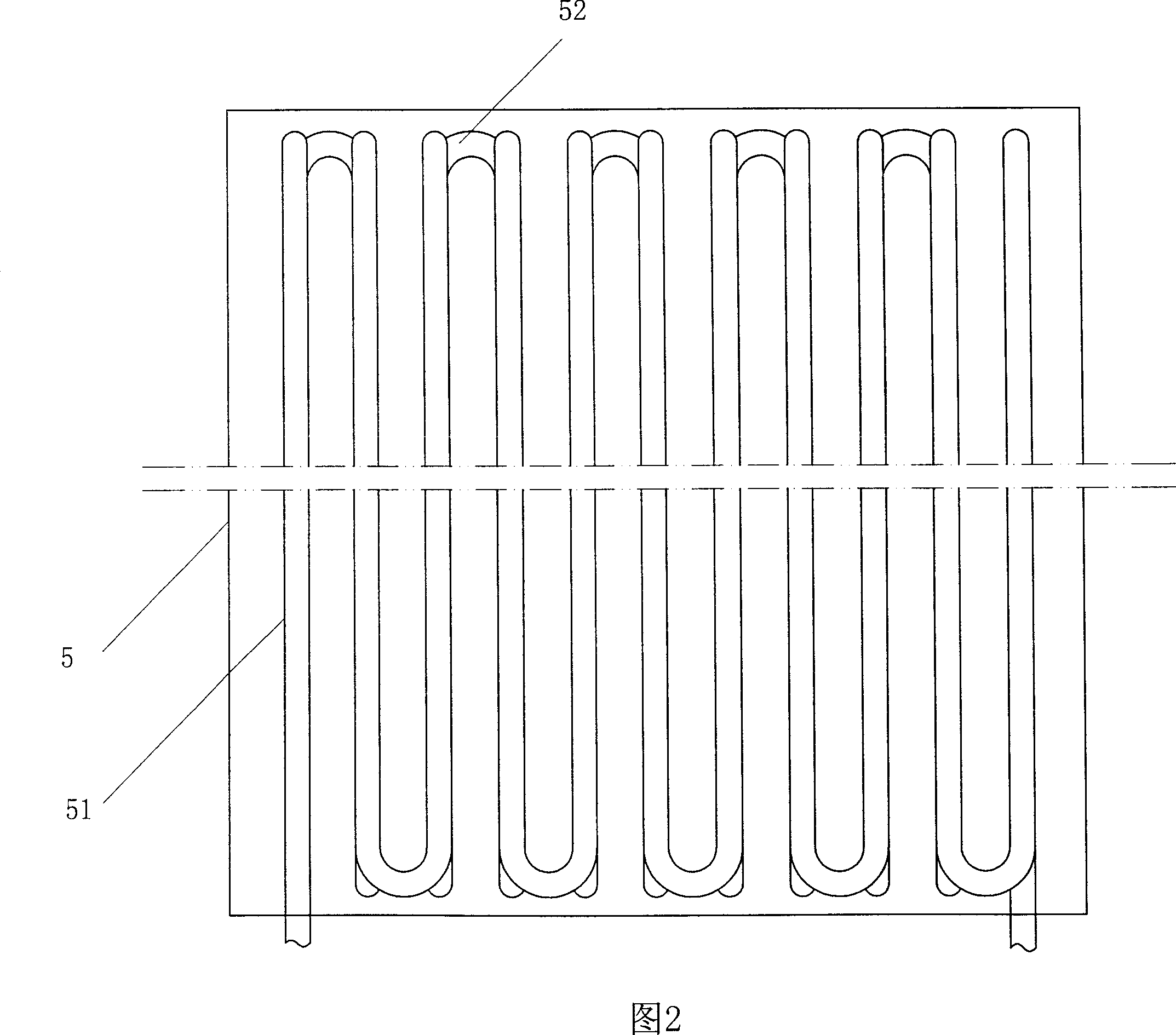

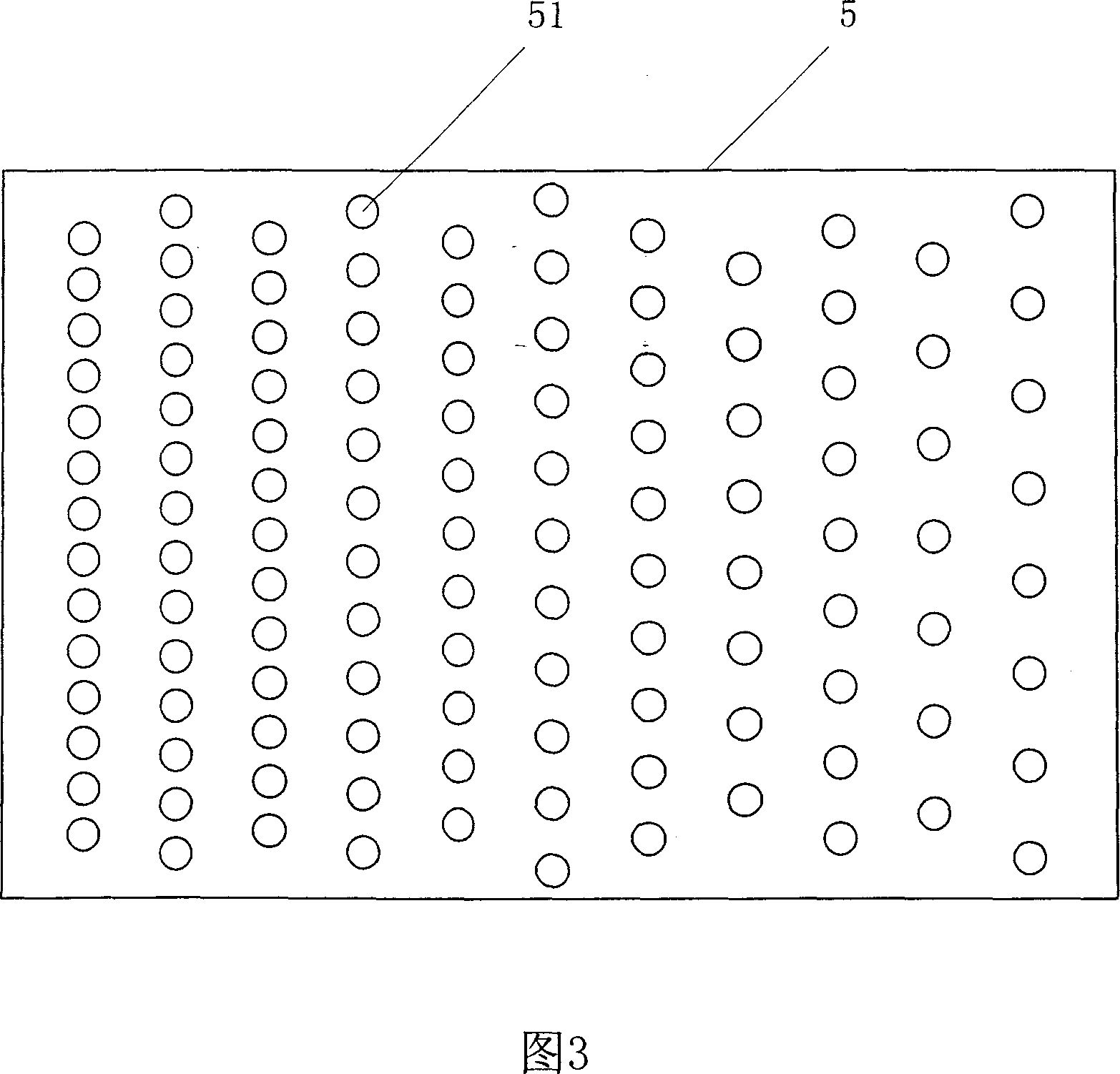

[0018] See Fig. 1, the present invention relates to a kind of freeze-drying machine, comprise casing 1, refrigerating unit 2, vacuum pump 3 and heating plate 4, refrigerating unit 2 has compressor 21, heat exchanger 22, expansion valve 23 and evaporator 24; The heating plate 4 is arranged at the front part of the box body 1, and the evaporator 24 of the refrigerating unit 2 is arranged at the rear part of the box body 1; the outside of the box body 1 is provided with an electric heating oil tank 91 and a thermal oil pump 92 which provide heat energy for the heating plate 4. The heating plate (4) is made of pure copper with good heat transfer and radiation performance, the surface is blackened, and there is a heating fluid channel inside. The inlet of the channel is connected to the thermal oil pump 92, and the outlet of the channel is connected to the electric heating oil tank 91. The thermal oil pump 92 delivers the thermal oil to the coil of the heating plate 4 for thermal ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com