Vacuum sweeper sucker structure with automatic avoiding function

A technology for automatic avoidance and vacuuming vehicles, which is applied in road cleaning, construction, cleaning methods, etc. It can solve problems such as unstable driving routes, easy collisions with road shoulders and obstacles, and uneven driver skills, and achieves a simple structure , Large dust collection range, strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

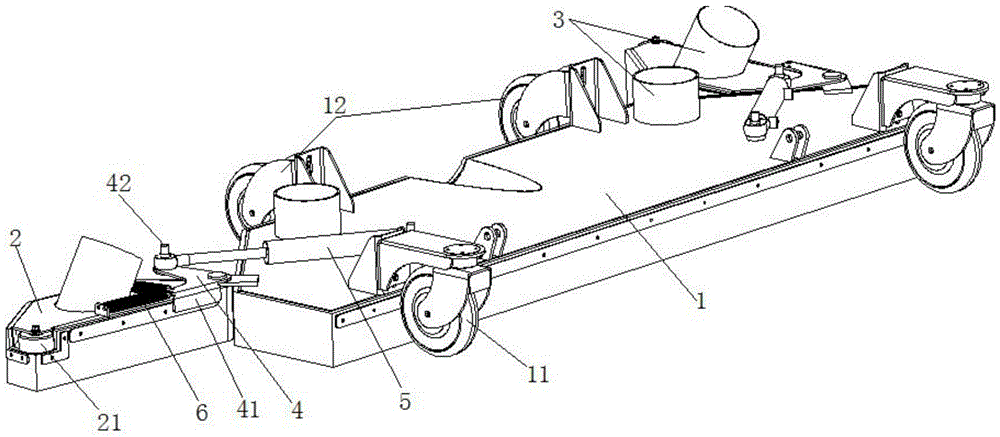

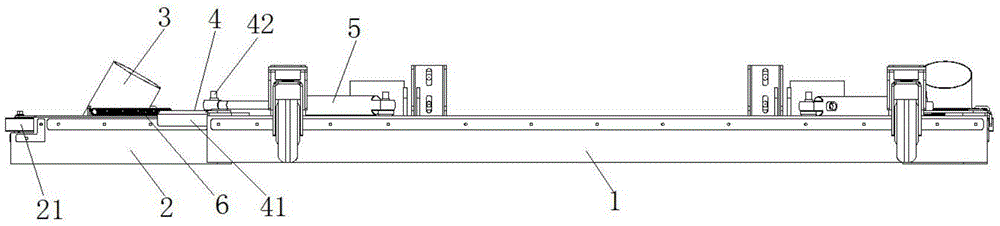

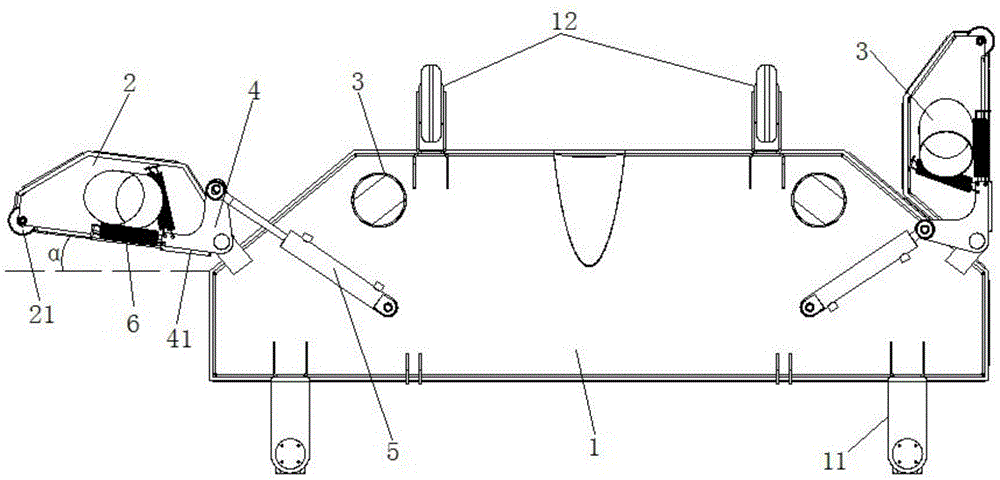

[0029] Example: such as figure 1 As shown, the suction cup structure of the vacuum cleaner that can automatically avoid in this embodiment includes a main suction cup 1 and two auxiliary suction cups 2, and the two above-mentioned auxiliary suction cups 2 are respectively rotated and installed on both sides of the above-mentioned main suction cup 1, and the above-mentioned main suction cup 1 and The auxiliary suction cups 2 are shell structures with lower ends open, the top of the main suction cup 1 and the top of the auxiliary suction cup 2 are provided with a dust suction pipe 3 connected to the inside of the housing, and the top of the auxiliary suction cup 2 close to the main suction cup 1 is fitted with a Rotating member 4, the rotating member 4 is rotatably installed on the above-mentioned main suction cup 1, and the top of the above-mentioned main sucking cup 1 is symmetrically provided with two drive mechanisms 5 corresponding to the above-mentioned rotating member 4 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com