Electric vacuum cleaner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

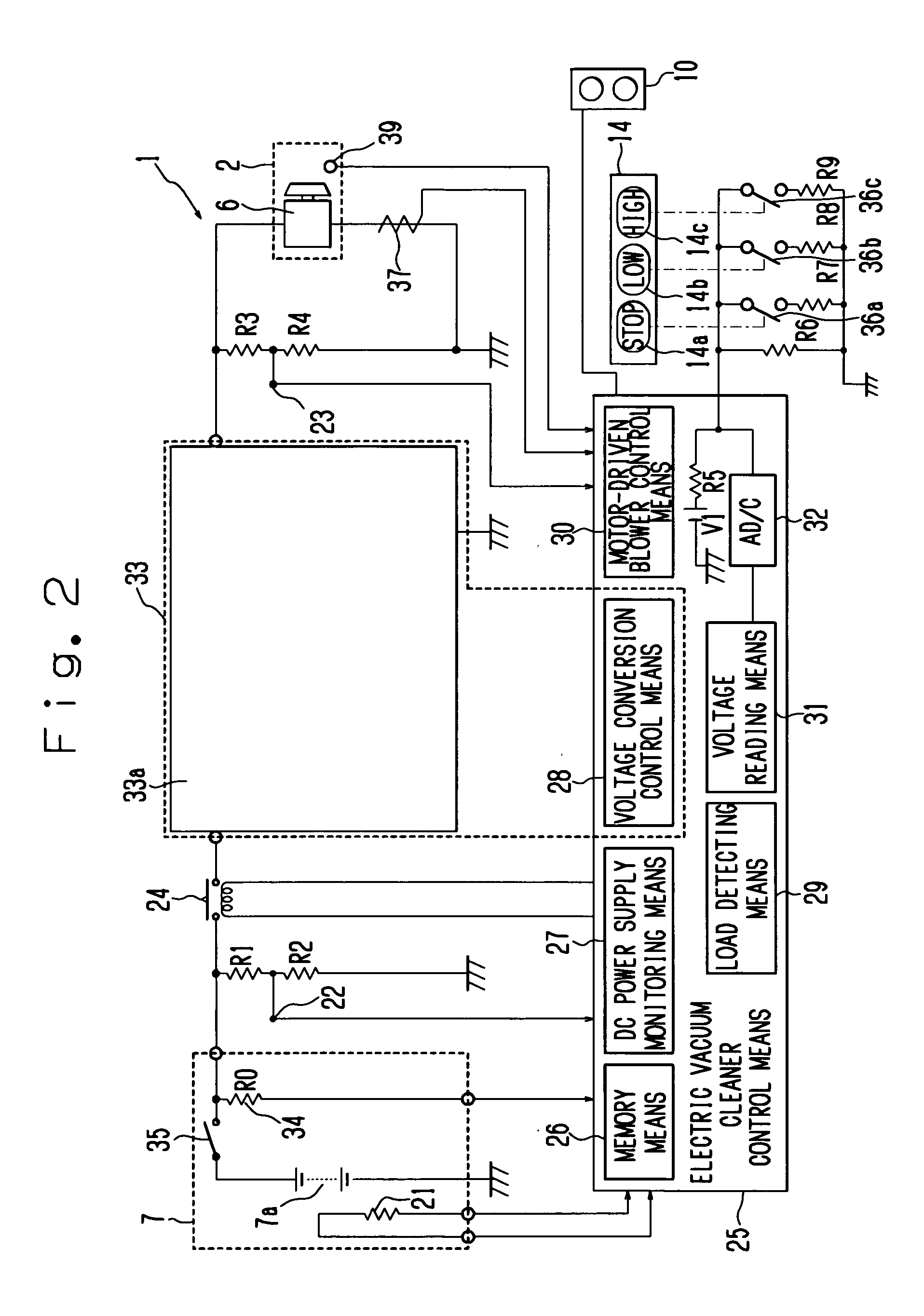

[0036] A first embodiment of the present invention will be described with reference to FIGS. 1 through 17.

[External Configuration]

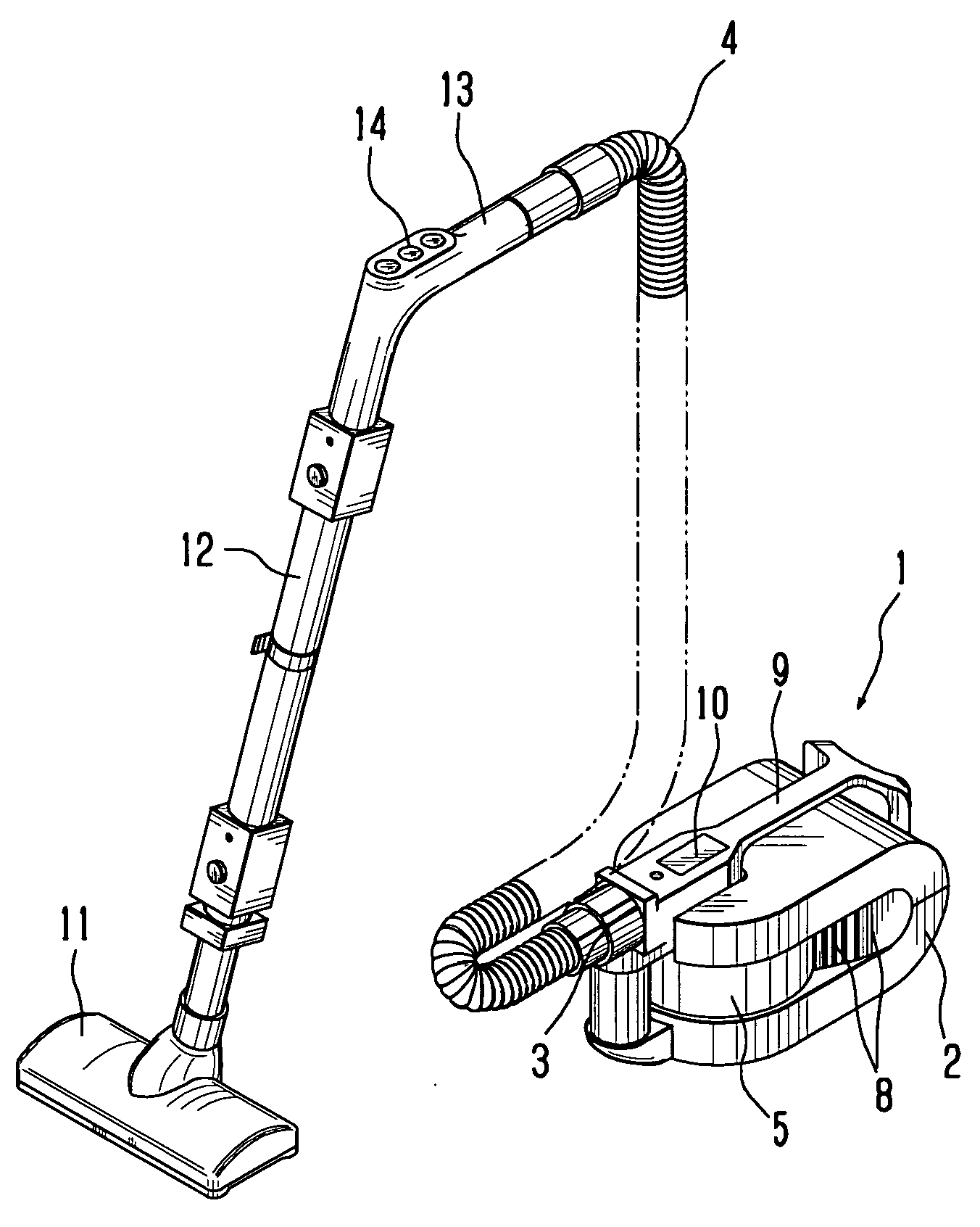

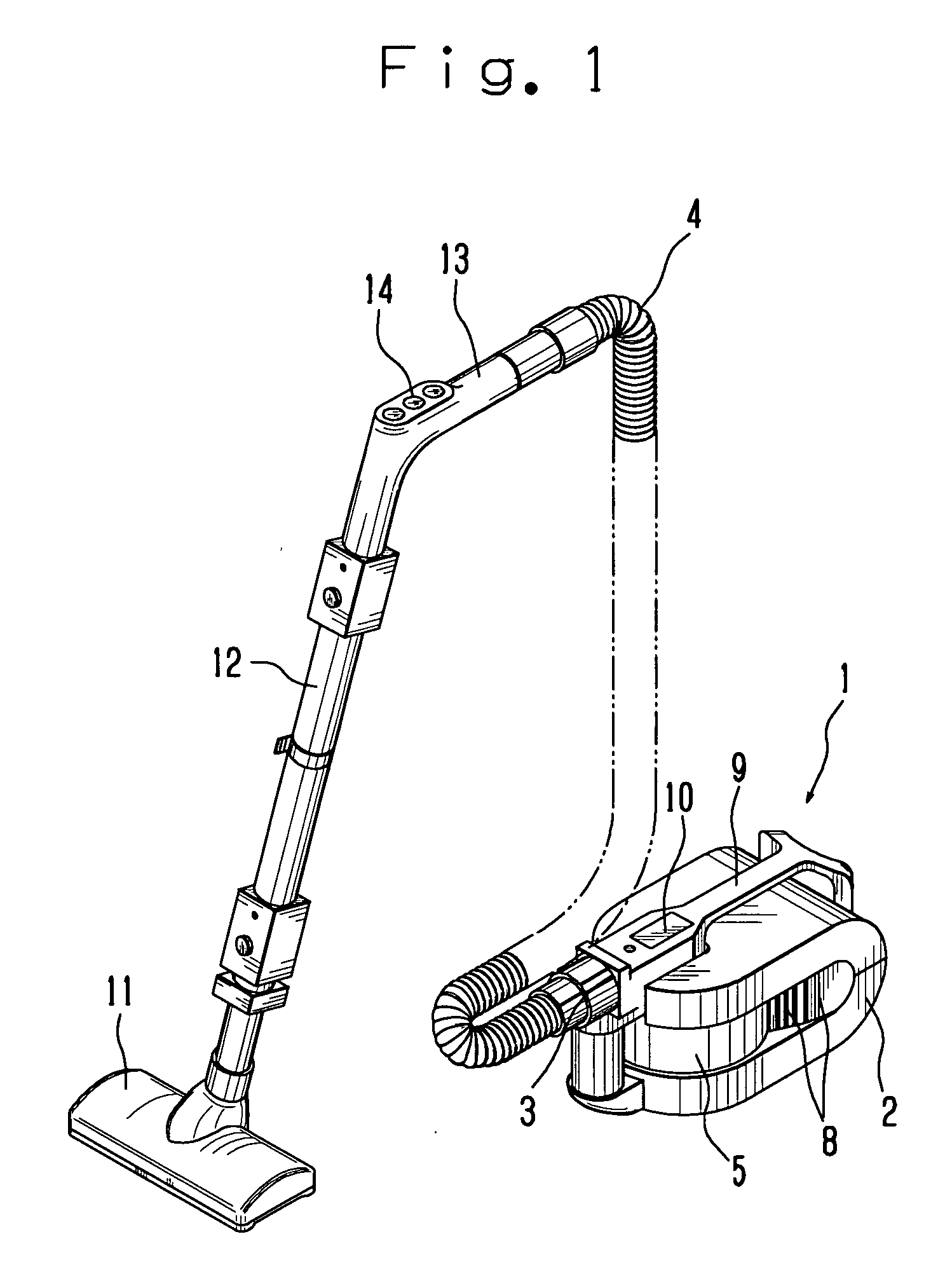

[0037]FIG. 1 is a perspective view showing an external configuration of an electric vacuum cleaner according to the embodiment of the present invention. As shown in FIG. 1, the electric vacuum cleaner 1 according to the present embodiment includes a hose body 4 detachably mounted to an inlet 3 attached to a case 2.

[0038] A dust cup 5 used as a dust chamber, a motor-driven blower 6, and a DC power supply (see FIG. 2) are provided within the case 2. A plurality of exhaust ports 8, which communicate with the motor-driven blower 6 and are open in substantially front side directions, are defined in side plate portions of the case 2. A handle 9 used as a knob means is provided on its corresponding upper surface of the case 2. The handle 9 is formed so as to take a substantially Y-shape as seen in a plane surface. A display means 10 provided with a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com