Safety switch device for turning on and safely cutting off electric load

A technology for safety switches and electrical loads, applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of safety accidents, affecting the normal use of safety switches, and the failure of normal use of safety switches, and achieve the effect of preventing moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

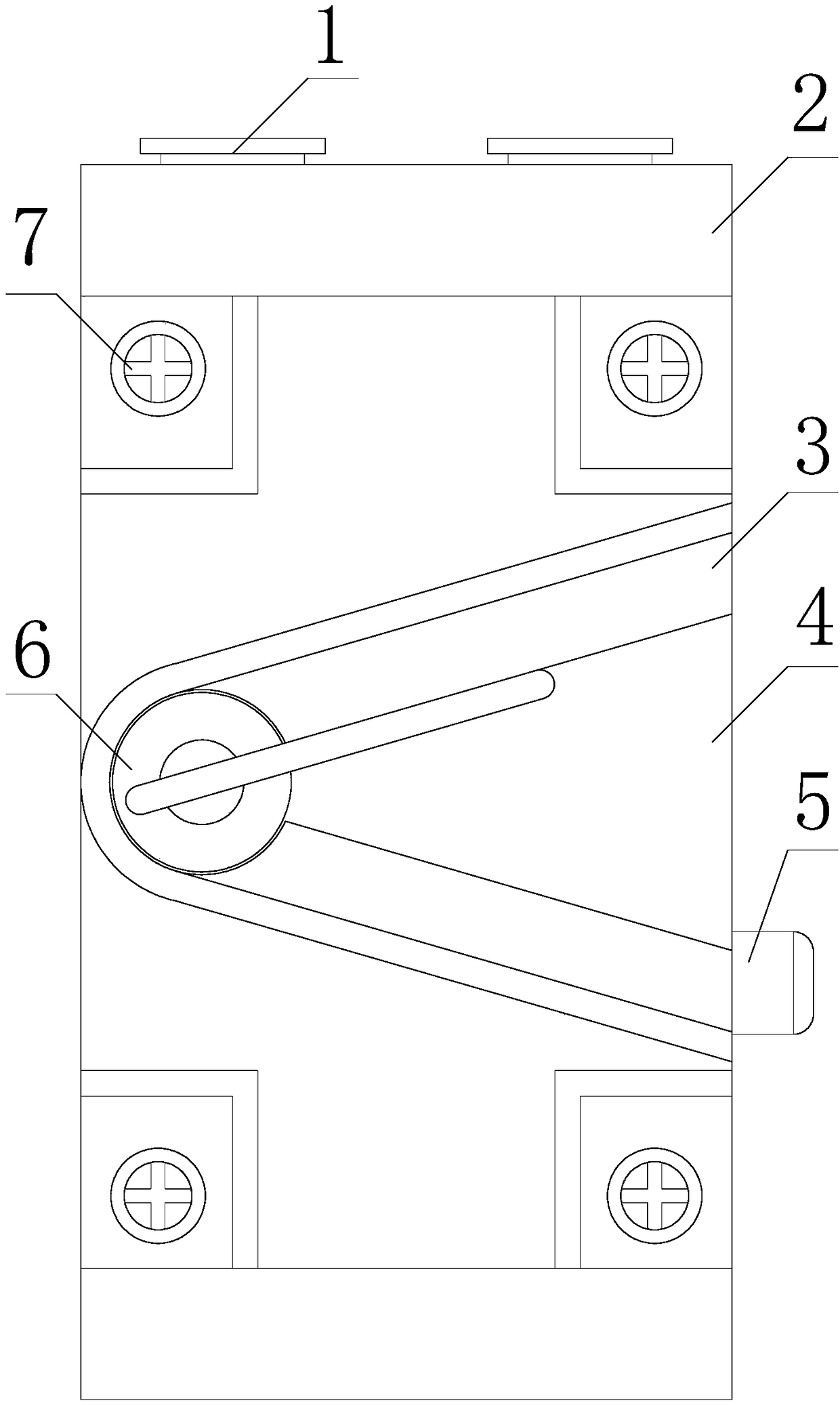

[0023] see Figure 1-Figure 4 , the present invention provides a safety switch device for switching on and safely cutting off electrical loads, the structure of which includes a connecting block 1, a mounting base 2, a limit plate 3, a safety switch host 4, an emergency cut-off button 5, an on switch 6, screws 7. The lower end of the connection block 1 is installed inside the installation seat 2, the lower surface of the installation seat 2 is attached to the upper surface of the safety switch host 4, the limit plate 3 is welded to the front surface of the safety switch host 4, and the The left end of the emergency cut-off button 5 is installed inside the right side of the safety switch host 4 by embedding, the on switch 6 is installed on the front surface of the left end of the safety switch host 4, and one end of the on switch 6 is attached to the limit plate 3, The screw 7 is threadedly connected with the front surface of the safety switch host 4 .

[0024]The safety switc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com