Device for removing water from waste combustion tail gas

A waste combustion and exhaust gas technology, applied in the direction of combustion method, combustion type, deodorization, etc., can solve the problems of inability to separate liquids, doping harmful substances, environmental pollution, etc., and achieve the effect of preventing random discharge and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

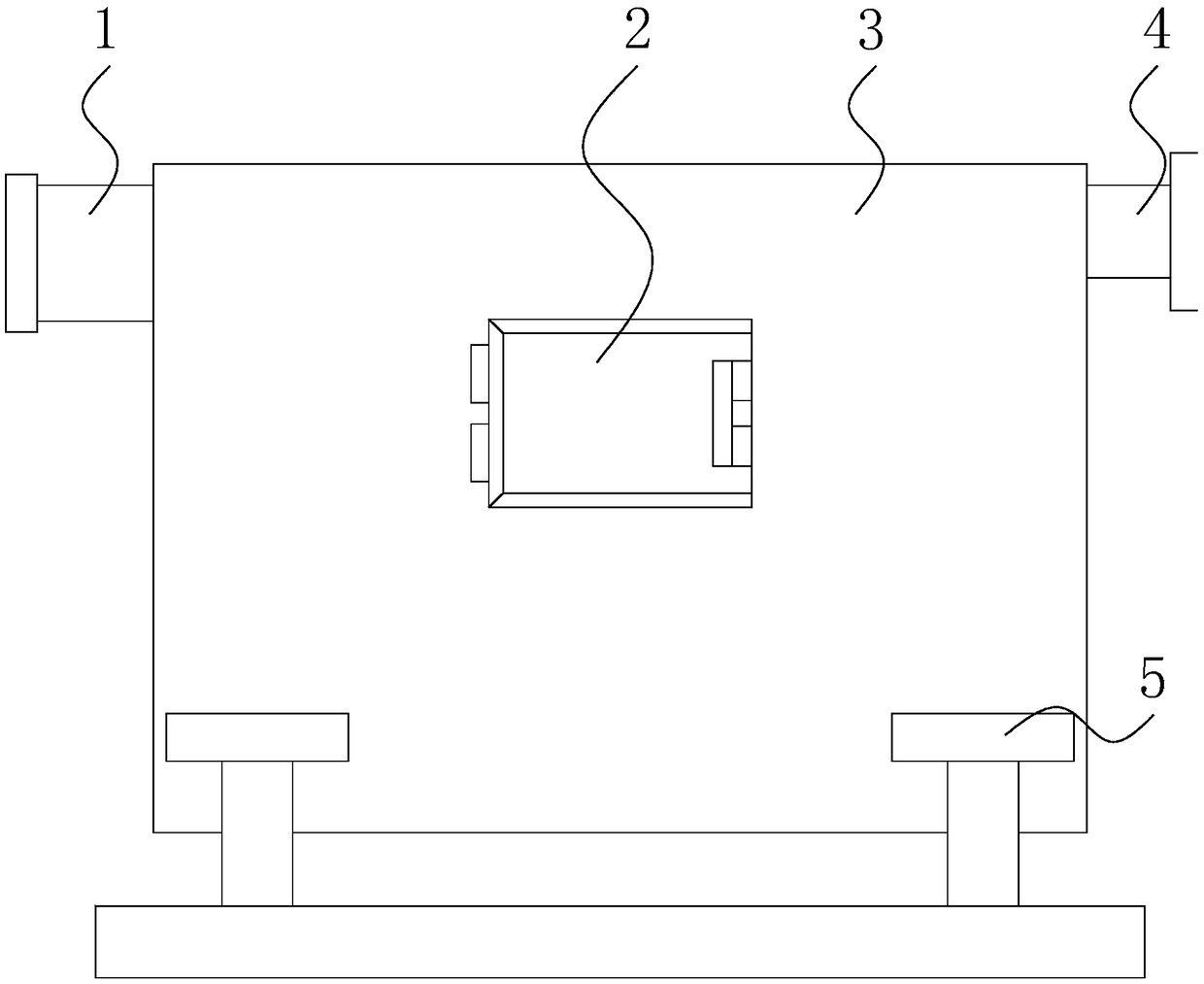

[0024] see Figure 1-Figure 5, the present invention provides a water removal device for waste combustion tail gas, the structure of which includes a purification outlet 1, a box door 2, a water removal host 3, an exhaust gas inlet 4, and a support base 5, and the purification outlet 1 is installed on the water removal host by embedding 3 on the left inner upper end, the box door 2 is hinged to the front surface of the water removal main machine 3, the left end of the exhaust gas inlet 4 is installed on the right inner upper end of the water removal main machine 3 by embedding, and the lower end of the water removal main machine 3 is welded to Support base 5 upper ends.

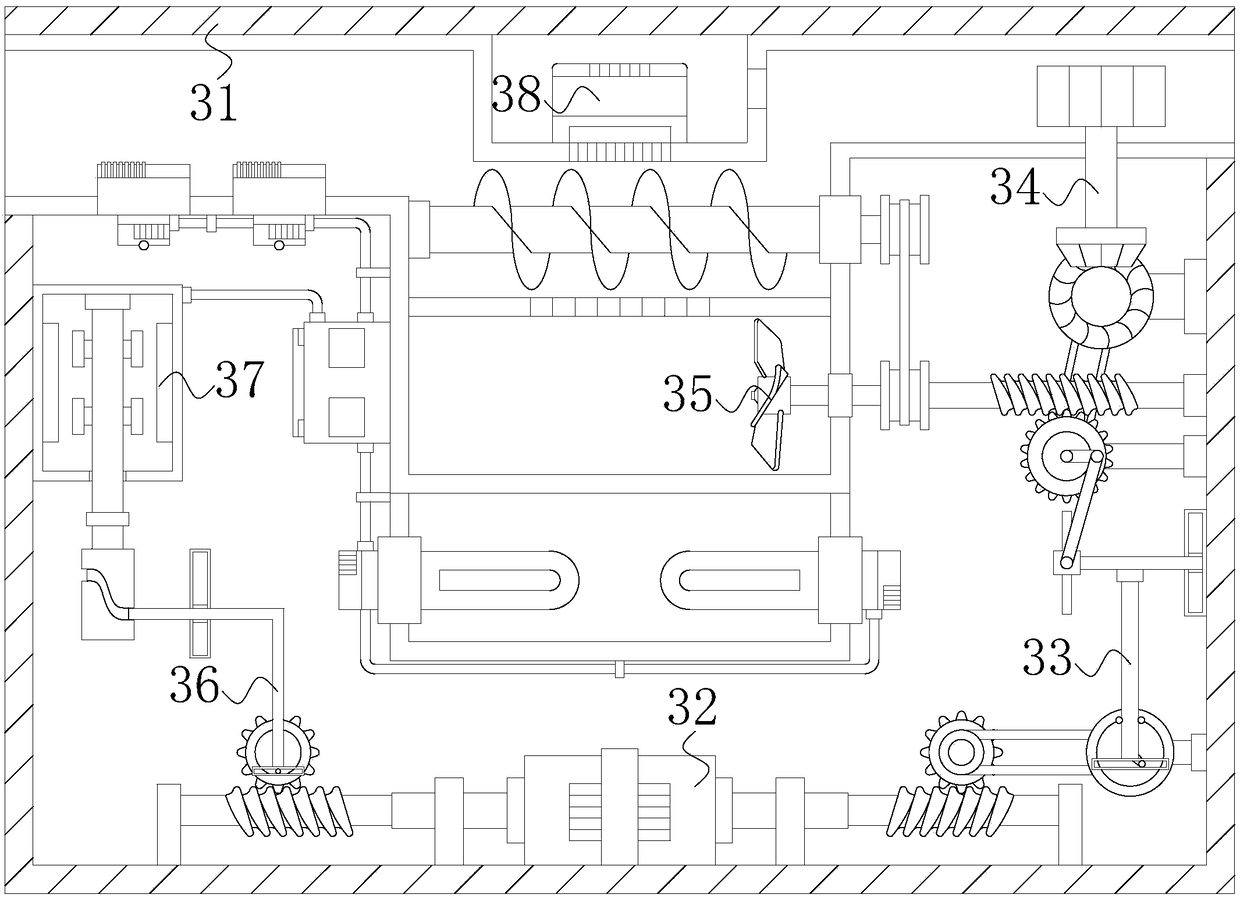

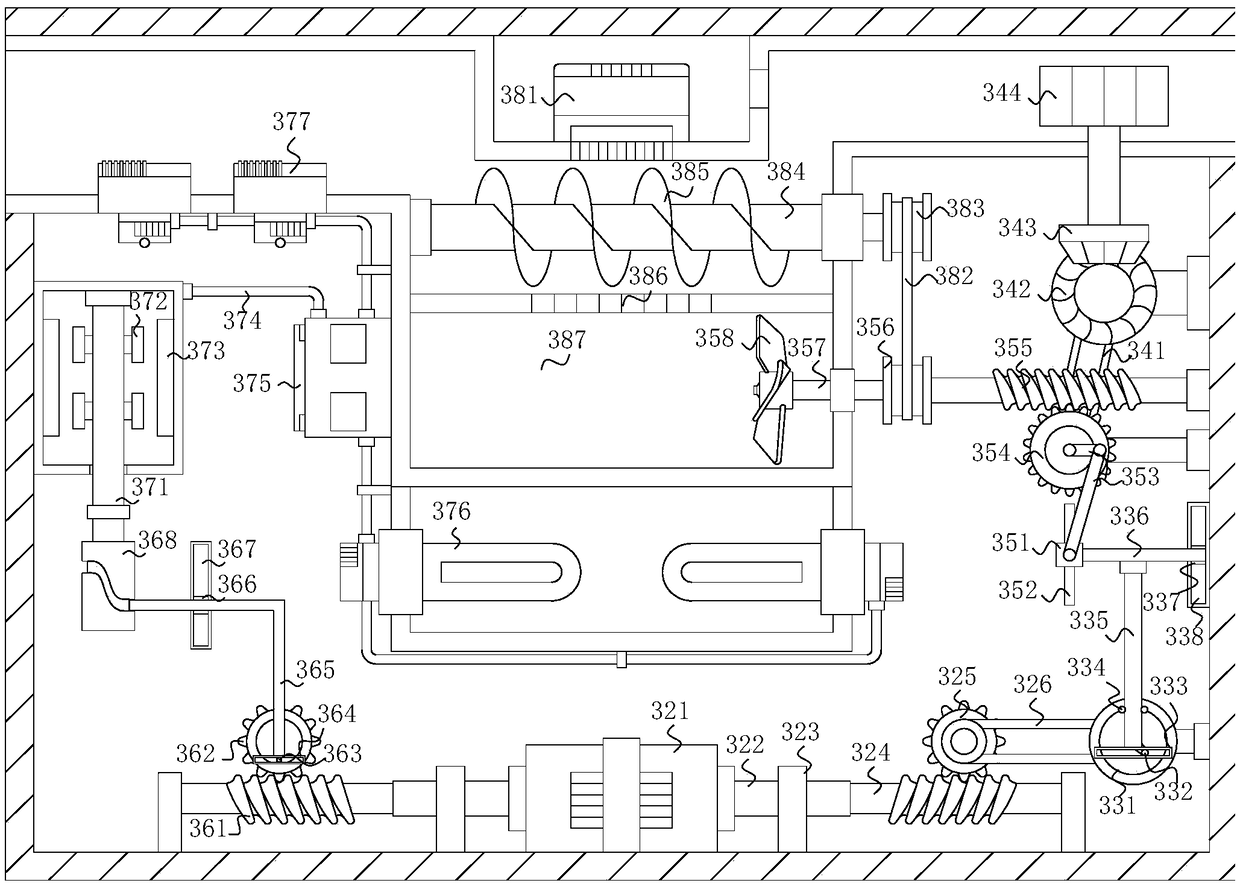

[0025] The main machine 3 for removing water comprises a main machine shell 31, a power mechanism 32, a driving mechanism 33, an air intake mechanism 34, a wind force mechanism 35, a transmission mechanism 36, a power supply mechanism 37, and a water collection mechanism 38. The outer surface of the lower end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com