Engine radiator

A radiator and engine technology, applied in engine components, machines/engines, engine cooling, etc., can solve problems such as poor heat dissipation, reduce heat dissipation efficiency, affect radiators, etc., to achieve better heat dissipation effect, Better effect, ensure the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

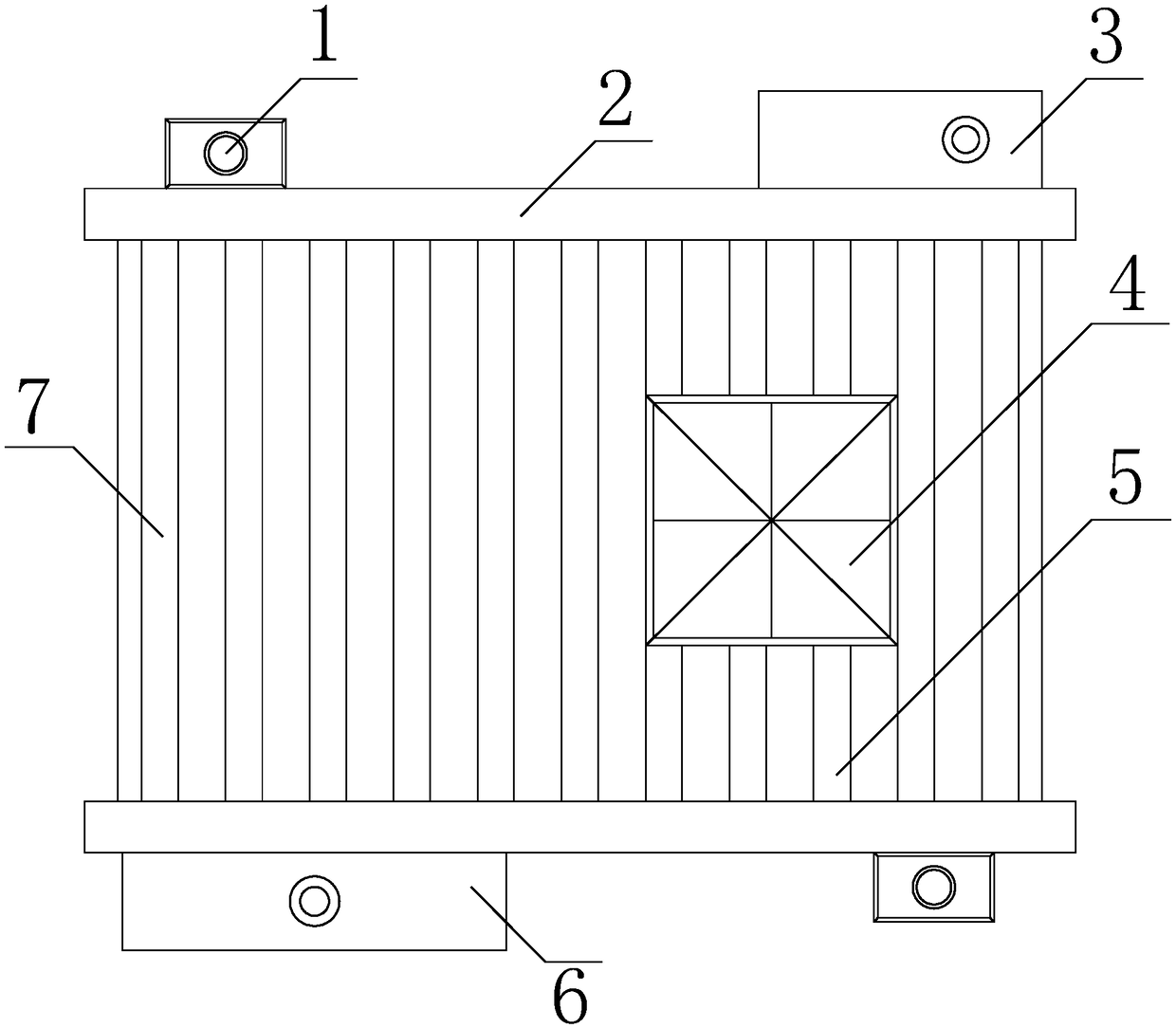

[0024] see Figure 1-Figure 5, the present invention provides an engine radiator, the structure of which includes a lifting lug 1, a fixing seat 2, a water inlet 3, an air outlet 4, a heat dissipation body 5, a cooling water outlet 6, and a cooling fin 7, and the lifting lug 1 is fixedly installed on the fixing seat 2 on the upper surface on the left side, the upper surface on the right side of the fixing seat 2 is provided with a water inlet 3, the water inlet 3 is connected to the inside of the heat dissipation body 5, and the air outlet 4 is embedded in the right front surface of the heat dissipation body 5, so A cooling water outlet 6 is provided at the left lower end of the heat dissipation body 5 , and the heat dissipation fins 7 are embedded on the outer surface of the heat dissipation body 5 .

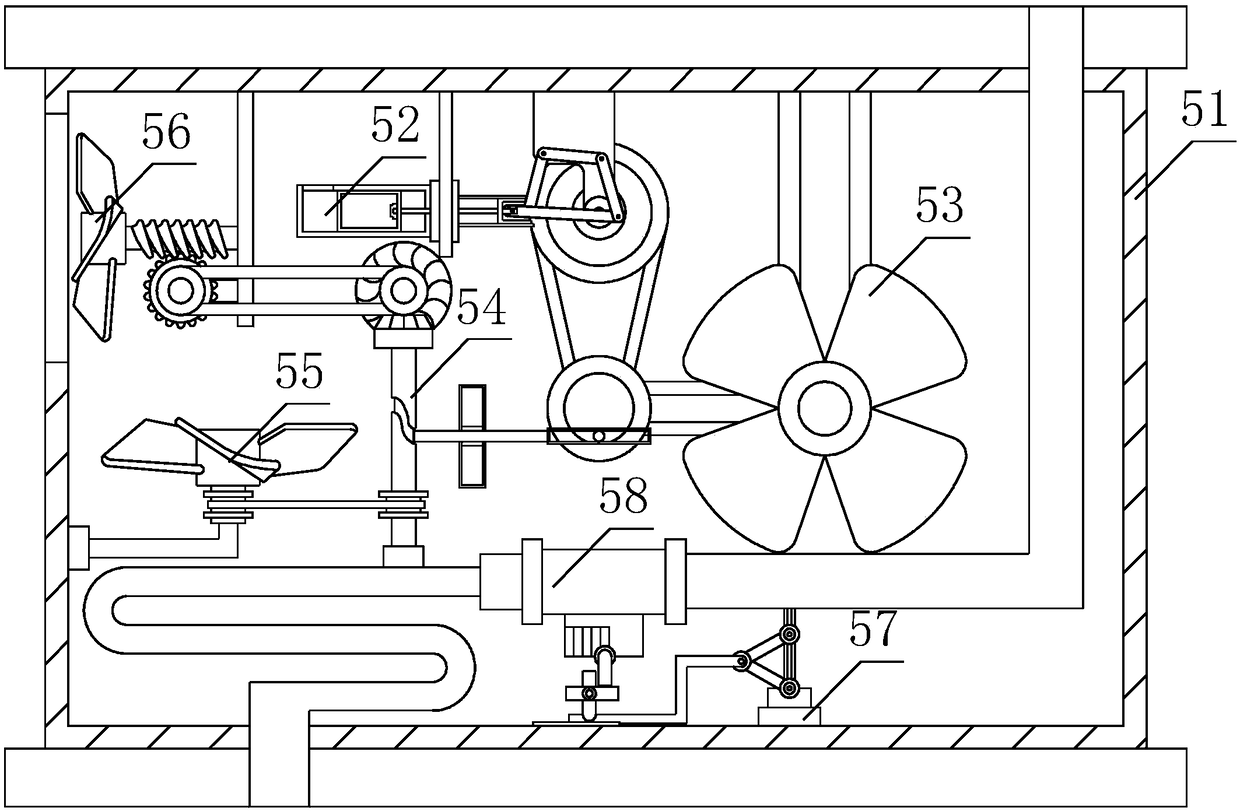

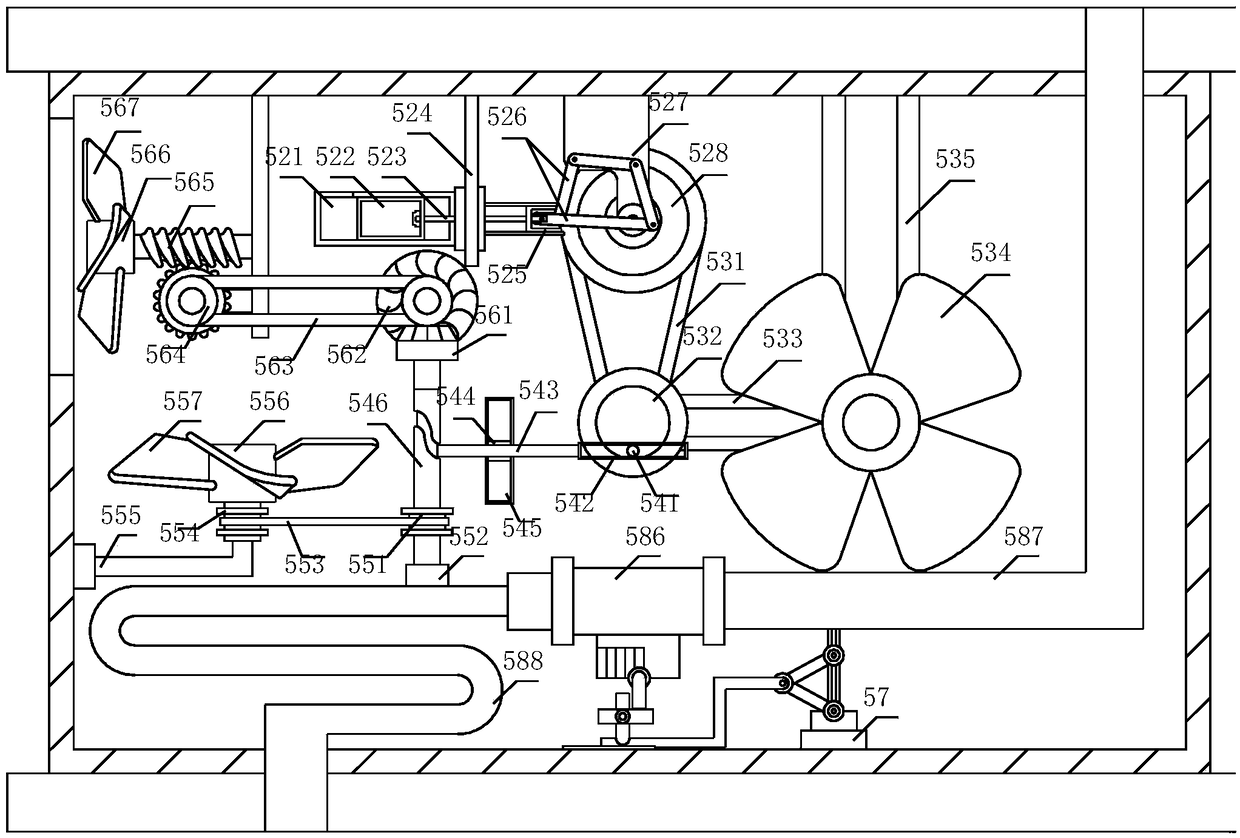

[0025] The heat dissipation main body 5 includes a host casing 51, a thermal transmission mechanism 52, a wind energy mechanism 53, a driving mechanism 54, a cooling mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com