Heat preservation type logistic trolley

A trolley and logistics technology, applied in trolleys, motor vehicles, multi-axle trolleys, etc., can solve the problems of ineffective cargo protection, cargo damage, moldy items, etc., and achieve the effect of preventing damage, deterioration, and mildew.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

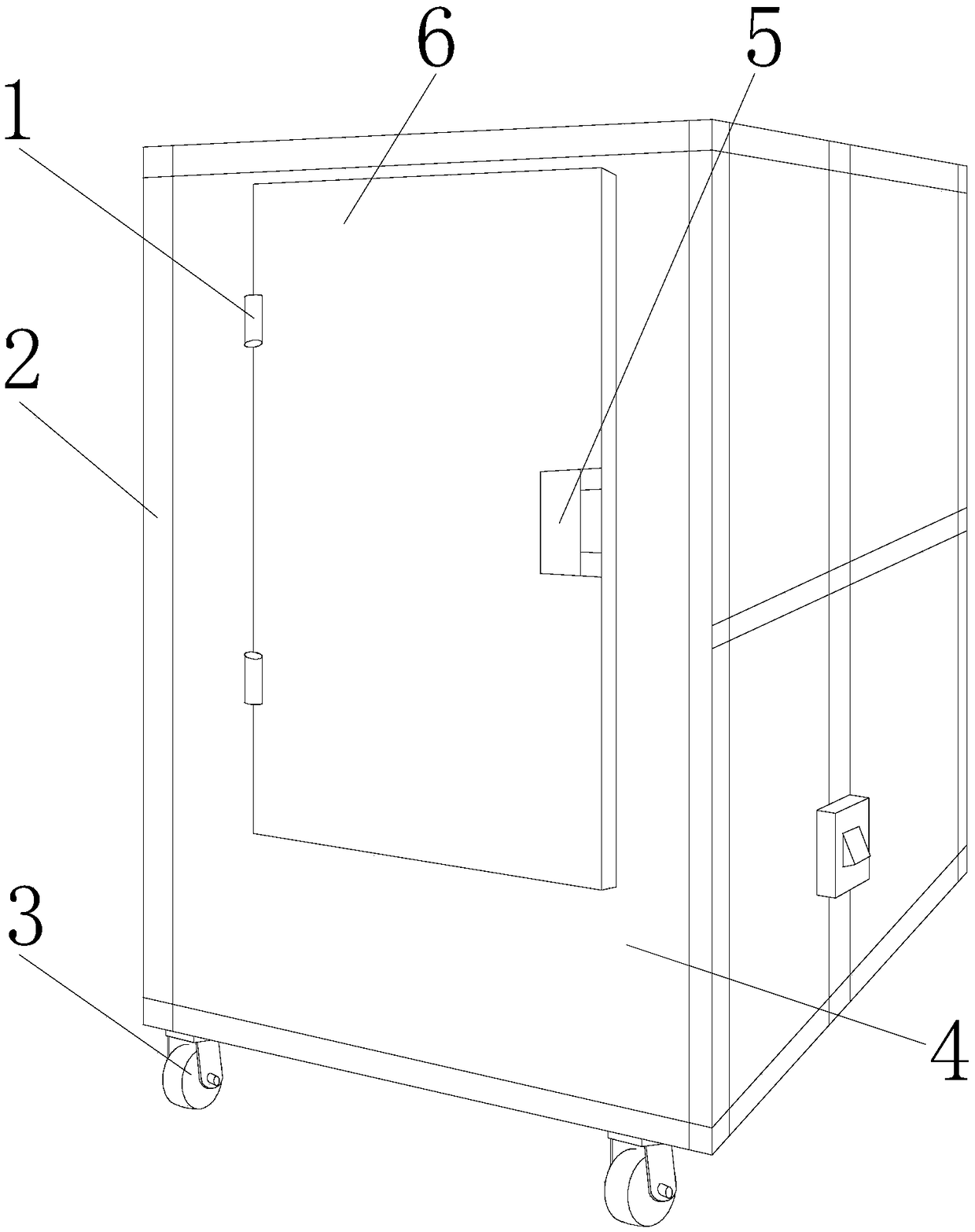

[0025] see Figure 1-Figure 5, the present invention provides an insulated logistics trolley, the structure of which includes a hinge 1, an anti-collision strip 2, a moving wheel 3, a trolley main body 4, a handle 5, and a box door 6, and the hinge 1 is welded to the left end of the front surface of the trolley main body 4 , the anti-collision strip 2 is fixedly installed around the main body 4 of the trolley, four moving wheels 3 are fixedly installed at the four corners of the main body 4 of the trolley, and the door 6 is installed on the main body 4 of the trolley through the hinge 1 front surface.

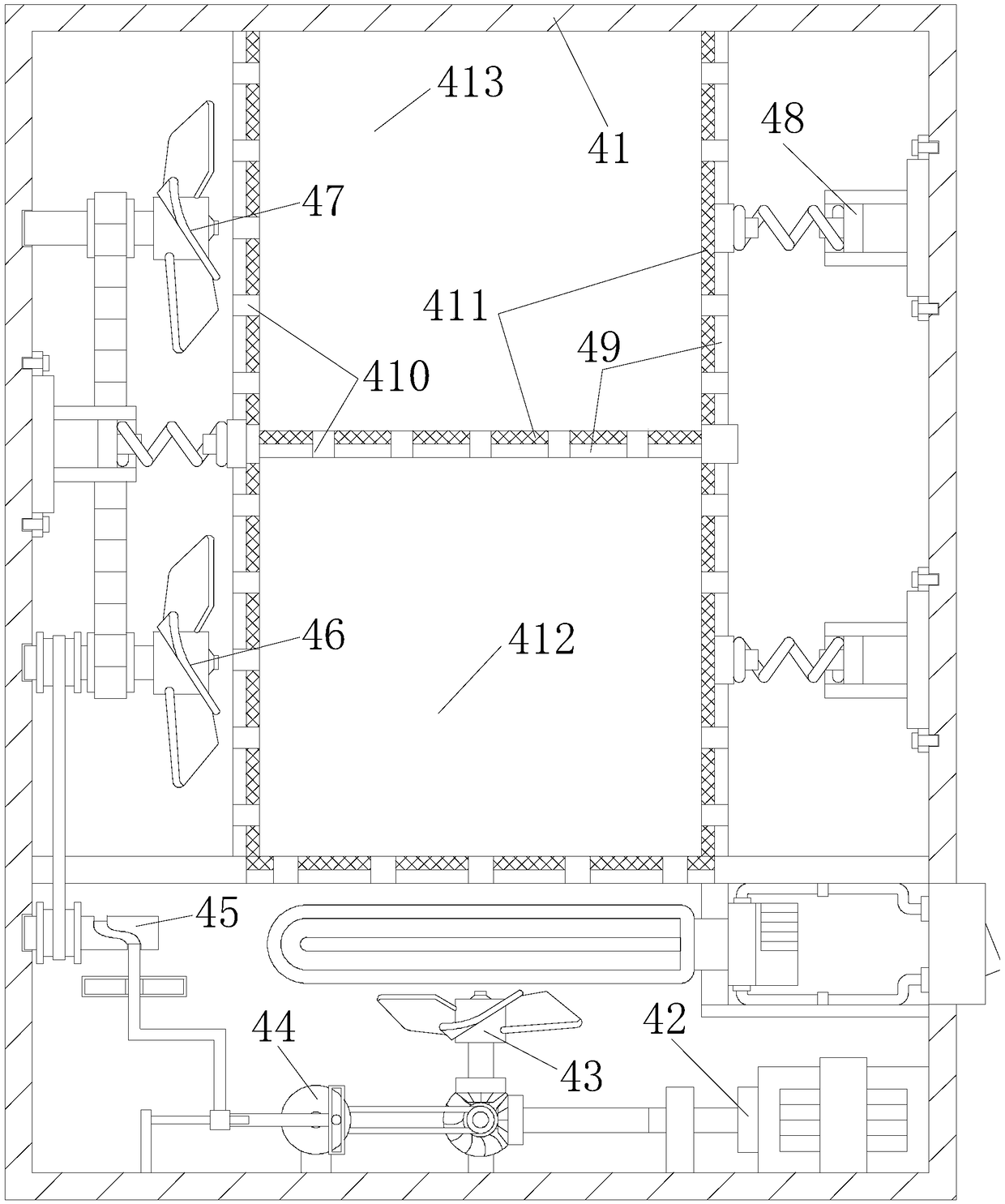

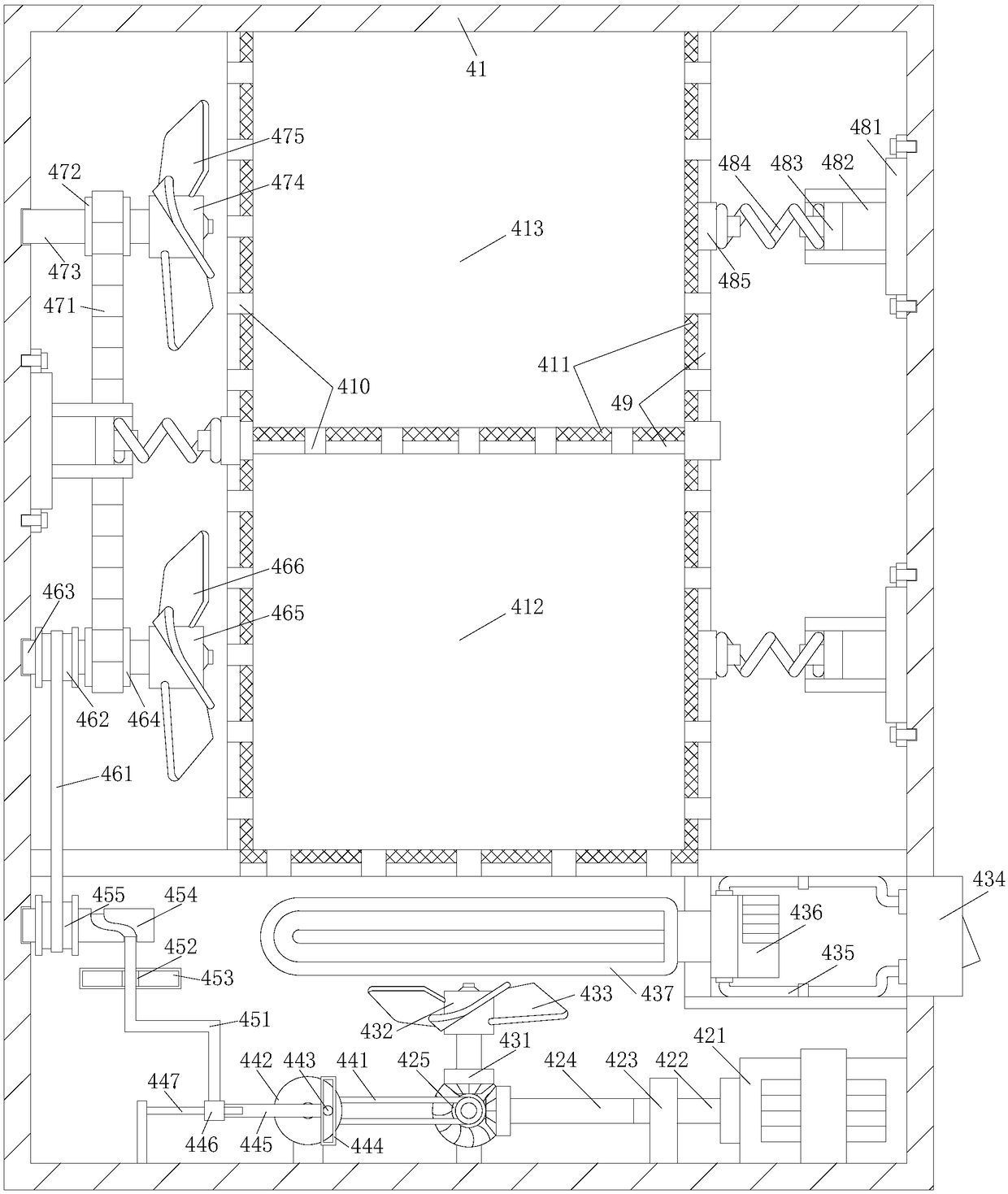

[0026] The trolley main body 4 includes a casing 41, a power mechanism 42, a blower mechanism 43, a transmission mechanism 44, a drive mechanism 45, a first heat dissipation mechanism 46, a second heat dissipation mechanism 47, a vibration damping mechanism 48, a support compartment 49, and cooling holes 410, crash pad 411, first storage room 412, second storage room 413, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com