Printing machine dust removal device

A technology of dust removal device and printing machine, which is applied in the direction of printing machine, printing, general parts of printing machinery, etc. It can solve the problems of workshop environment and product quality impact, scattering, dust drilling, etc., so as to improve the quality of workshop environment and product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

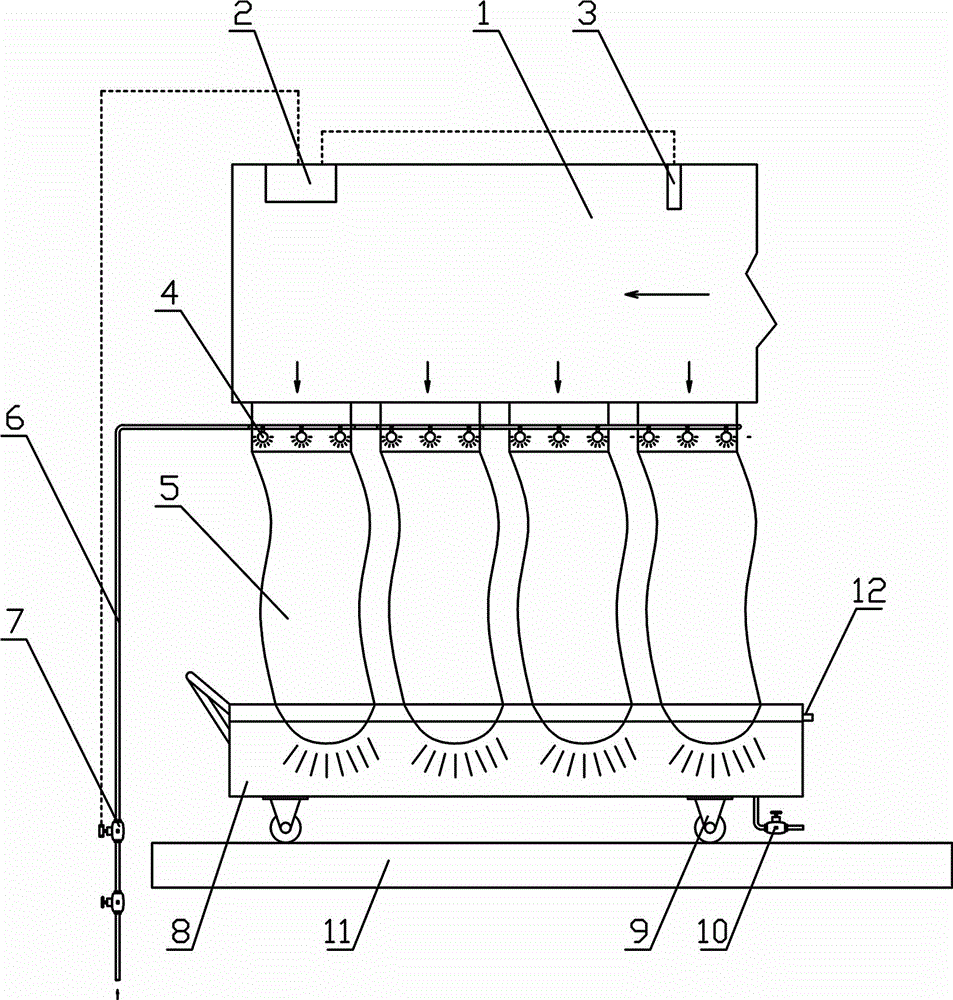

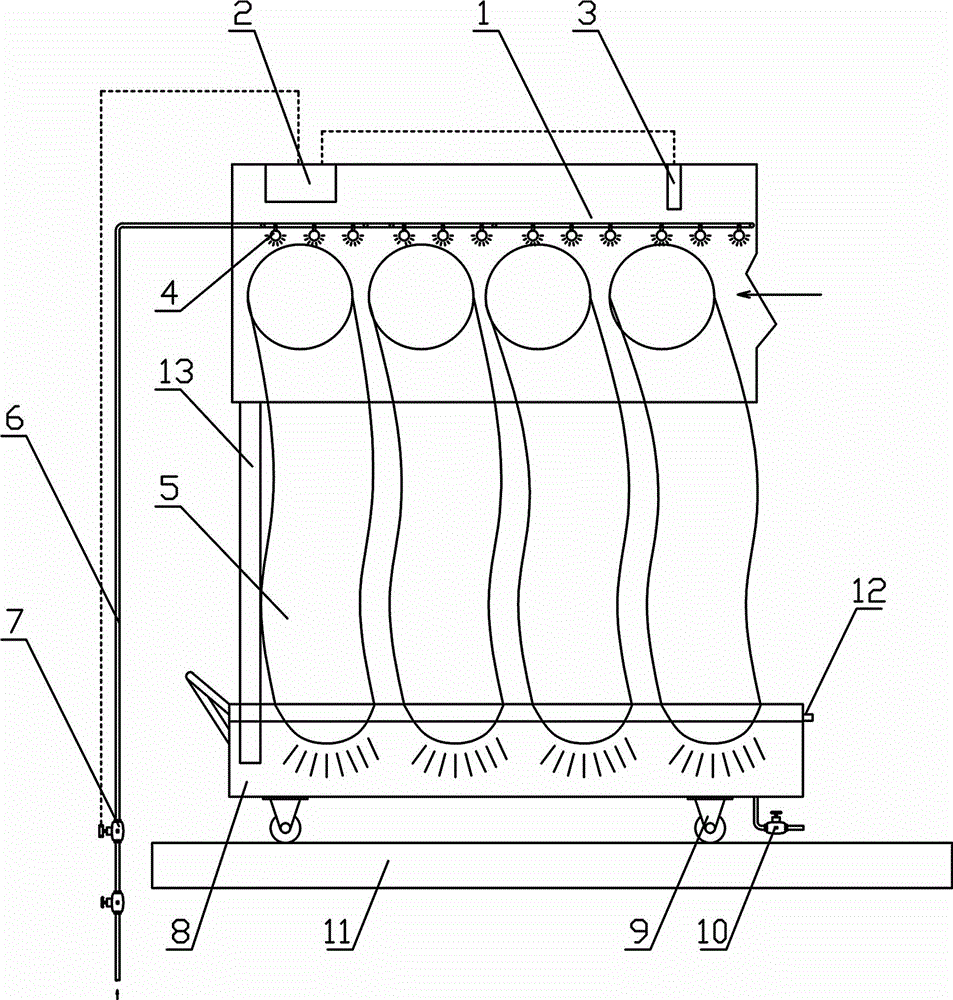

[0017] Such as figure 1 Among them, a printing machine dust removal device, the air inlet box 1 connected to the printing machine is connected to a plurality of cloth bags 5, a water receiving tray 8 is provided under the cloth bags 5, at least a part of the cloth bags 5 is located in the water receiving tray 8,

[0018] A plurality of atomizing nozzles 4 are also arranged in the air inlet box 1, and the atomizing nozzles 4 are connected with a water inlet pipe 6, and a solenoid valve 7 is arranged on the water inlet pipe 6. In this way, a more comprehensive dust removal work can be carried out on the air with a large ash content. Not only can the larger dust be collected in the cloth bag, but also the water mist produced by the atomizing nozzle can absorb the smaller dust, avoiding the smaller dust. Through the pores on the bag, it returns to the air again, affecting the workshop environment and product quality.

[0019] The preferred solution is as figure 1 Among them, clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com