Fabric surface dust removal device for fabric processing

A dust removal device and fabric technology, applied in the field of dust removal, can solve the problems of high cost of dust removal, effectiveness and poor effect of dust removal on the surface of fabrics, and achieve the effects of comprehensive dust removal, reduced adsorption, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

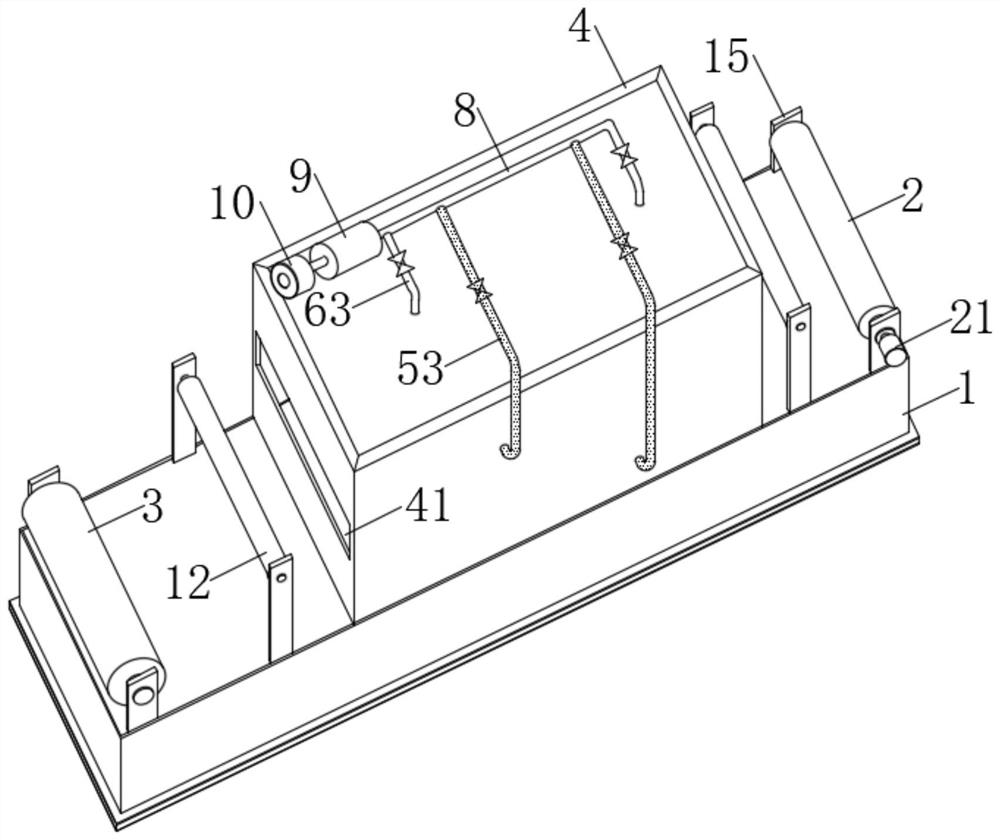

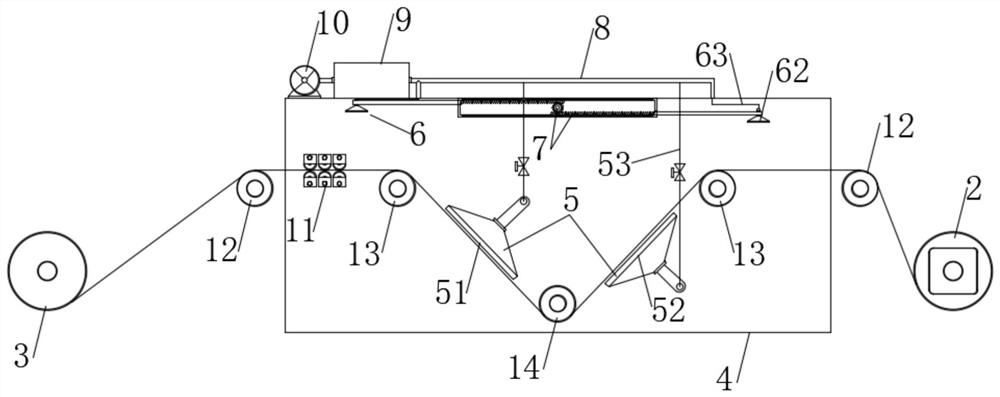

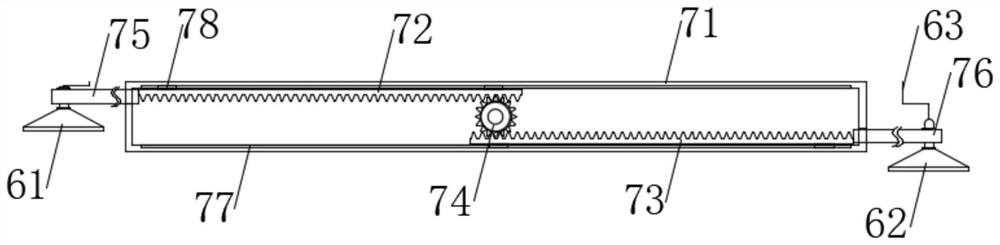

[0024] like Figure 1-5 As shown, this specific embodiment adopts the following technical solutions: a fabric surface dust removal device for fabric processing, comprising a fabric processing table 1 and a winding roller 2, and one side of the top of the fabric processing table 1 is rotated and installed with a support frame 15 Rewinding roller 2, one side of the rewinding roller 2 is fixedly installed with the output end of the rewinding motor 21 on the support frame 15 through a coupling, and the side of the top of the fabric processing table 1 away from the rewinding roller 2 is supported by Frame 15 is rotatably equipped with discharging roller 3, and the top of fabric processing table 1 between described winding roller 2 and discharging roller 3 is fixedly installed with dust removal protective cover 4, and described dust removal protective cover 4 is close to winding roller 2, puts Both sides of the feed roller 3 are provided with cloth guide openings 41, and the fabric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com