Polishing dust removal agent and dust removal process

A process and medicament technology, which is applied in the field of polishing dust removal medicament and dust removal process, can solve problems such as health threats, dust pollution, residues, etc., and achieve the effects of preventing inhalation hazards, improving safety, and preventing residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

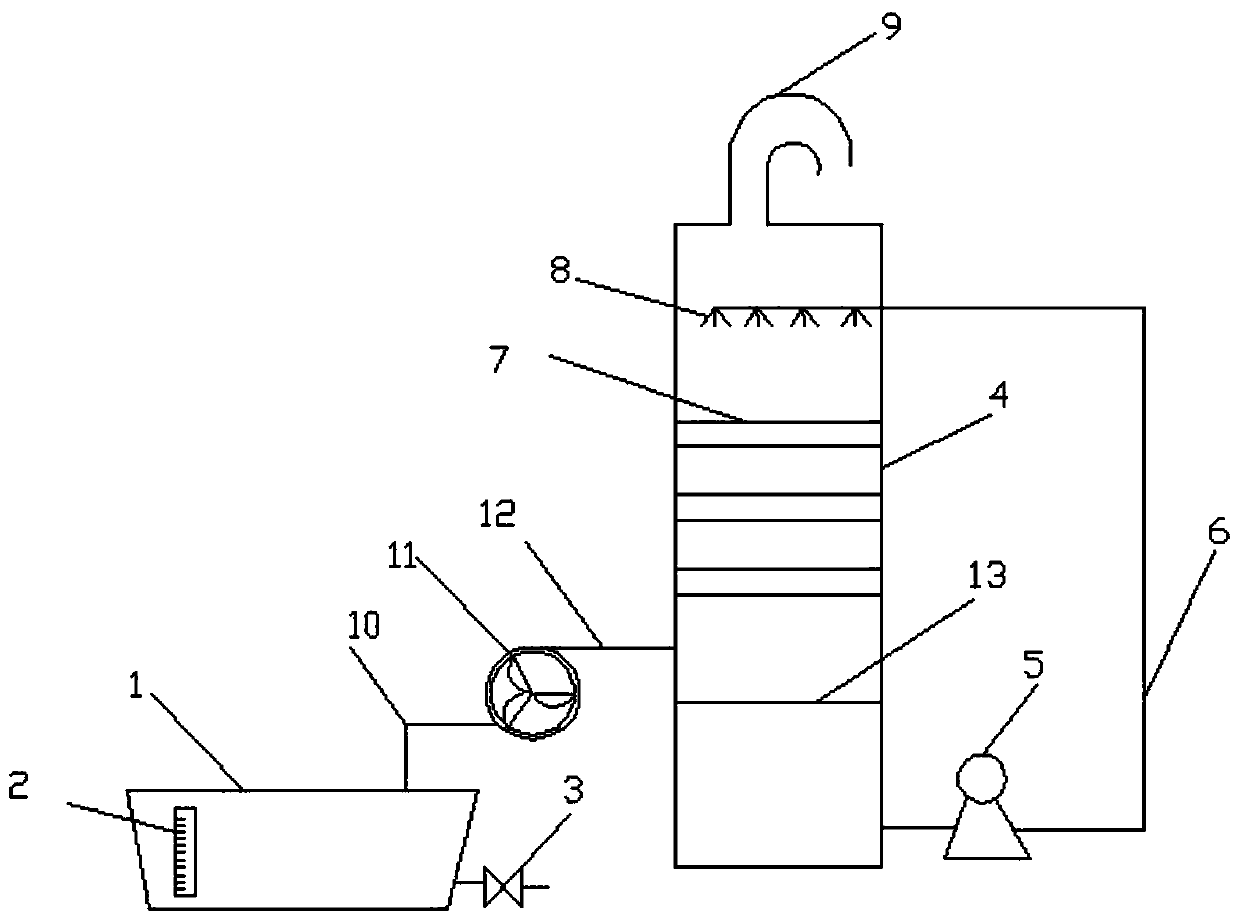

Image

Examples

preparation example Construction

[0056] In a preferred embodiment, the preparation method of the ionic liquid of the present invention comprises the following steps:

[0057] 1) heating N-methylimidazole to 40-50°C, adding butane sultone to react, washing and drying to obtain intermediate A;

[0058] 2) React intermediate A and p-toluenesulfonic acid at 110-130°C, lower the temperature to 90-100°C, wash and dry to obtain the ionic liquid.

[0059] The present invention reacts N-methylimidazole (CAS No.: 616-47-7) and butane sultone (CAS No.: 1633-83-6) to generate sulfonate-containing imidazole inner salt, and reacts with p-toluenesulfonic acid Generate imidazole acidic ionic liquids, containing both nitrogen cations and p-toluenesulfonate anions.

[0060] In order to improve the absorption speed of the medicament to dust, the applicant added an appropriate amount of ionic liquid to the medicament, and found that the addition of ionic liquid can greatly improve the absorption efficiency of the medicament to ...

Embodiment 1~15

[0104] Embodiments 1-15 provide a preparation method of polishing and dust-removing agent, comprising the following steps:

[0105] The preparation raw materials of the polishing and dust-removing agent are mixed to obtain the polishing and dust-removing agent.

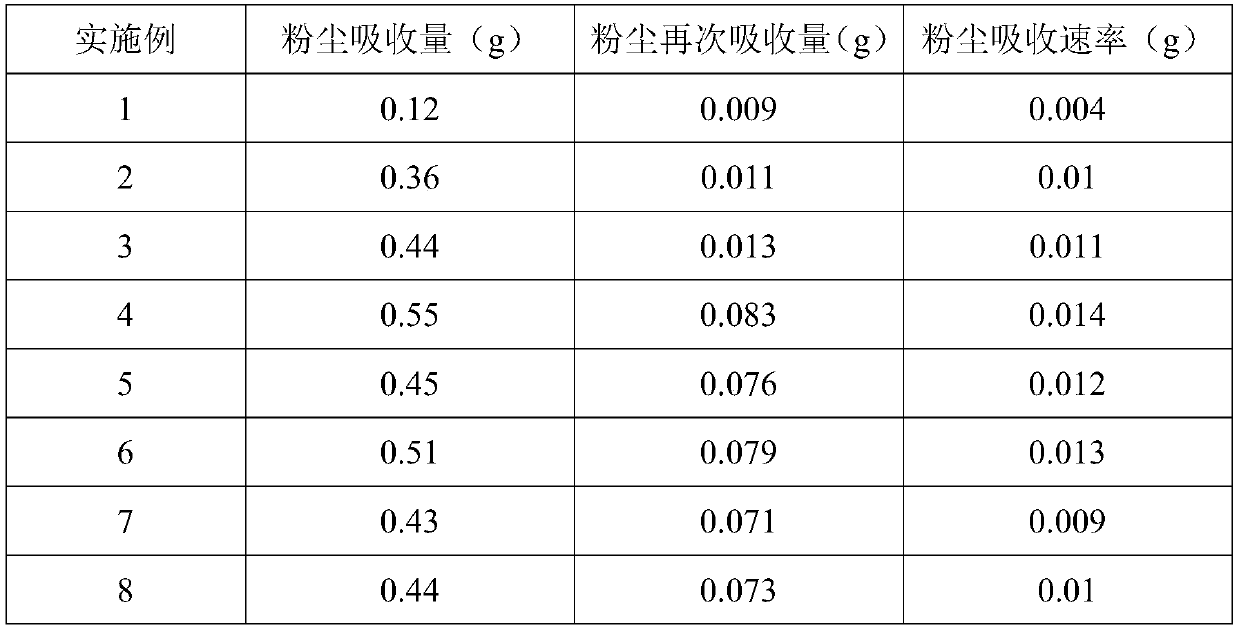

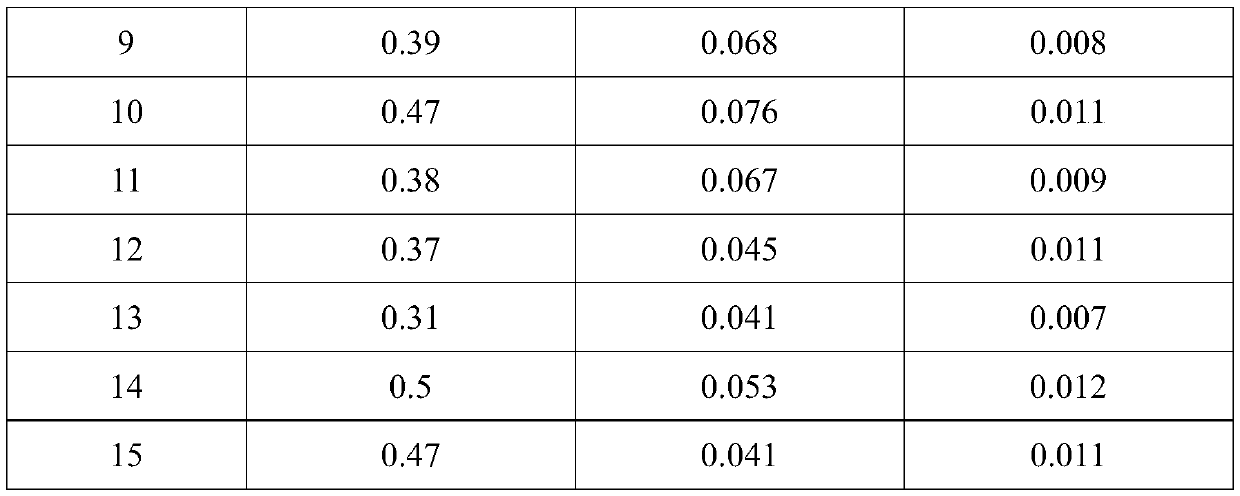

[0106] performance evaluation

[0107] 1. Dust absorption performance:

[0108] (1) Dust absorption: At 28°C, under normal pressure, add an equivalent amount of polishing dust removal agents provided in Examples 1 to 15 respectively in the dust absorption bottle, and then pass it into the magnesium alloy and aluminum alloy for polishing at a speed of 60mL / min. For the dust generated during the test, test the weight gain of the dust absorbing article until the weight of the absorbing article no longer changes to calculate the weight of the dust absorbed by the medicament. The results are shown in Table 2.

[0109] (2) Dust secondary absorption: After the medicaments provided in Examples 1 to 15 after absorbing the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com