Coal-fired boiler smoke efficient desulfurization and dedusting purification system for steam production

A technology for coal-fired boilers and steam production, which is applied in gas treatment, chemical instruments and methods, and gaseous effluent wastewater treatment, etc. It can solve the problems that the exhaust gas still contains serious particles, equipment cannot be recycled, and it is difficult to recycle, etc., to achieve Perfect dust removal, convenient for next use, and guaranteed dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

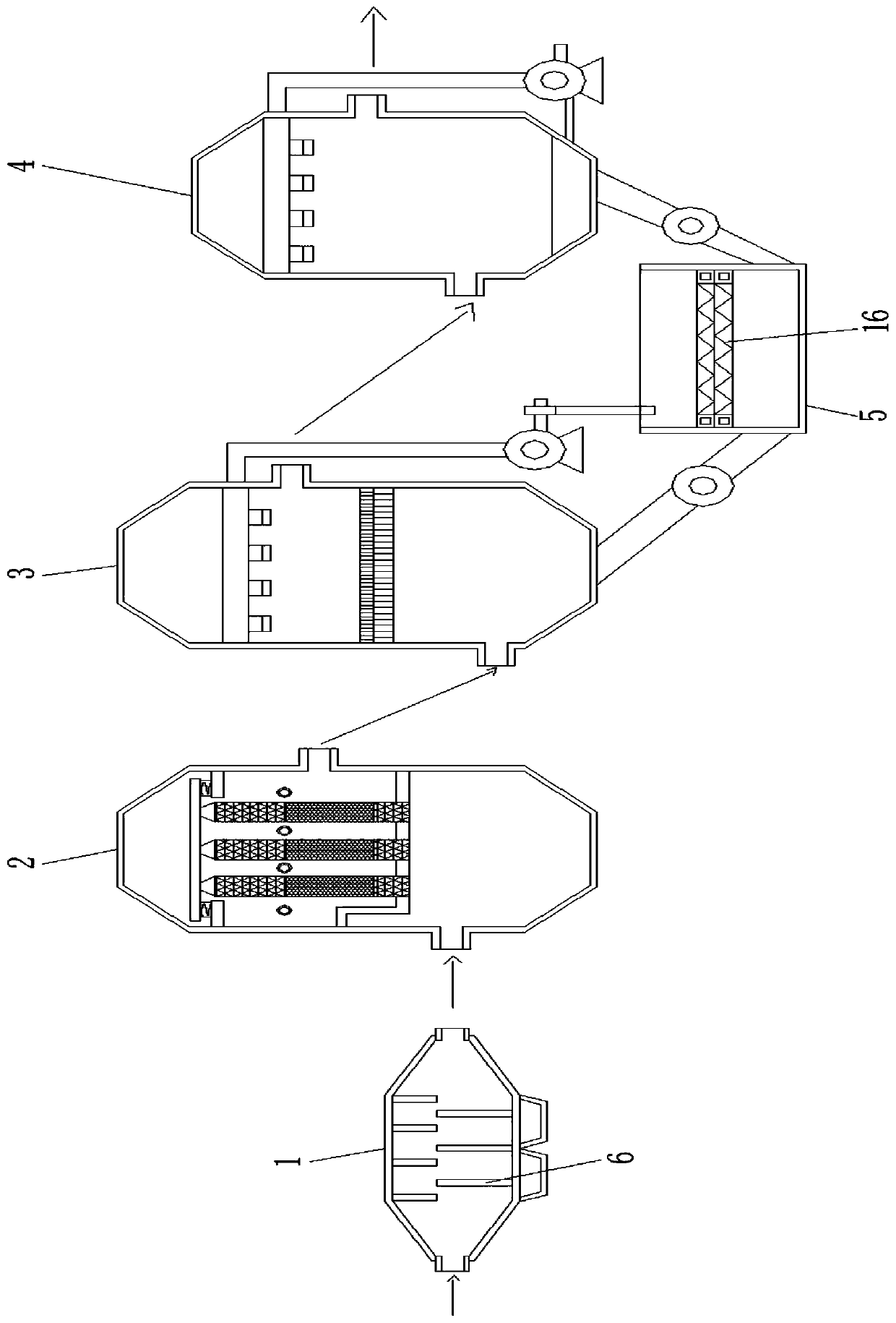

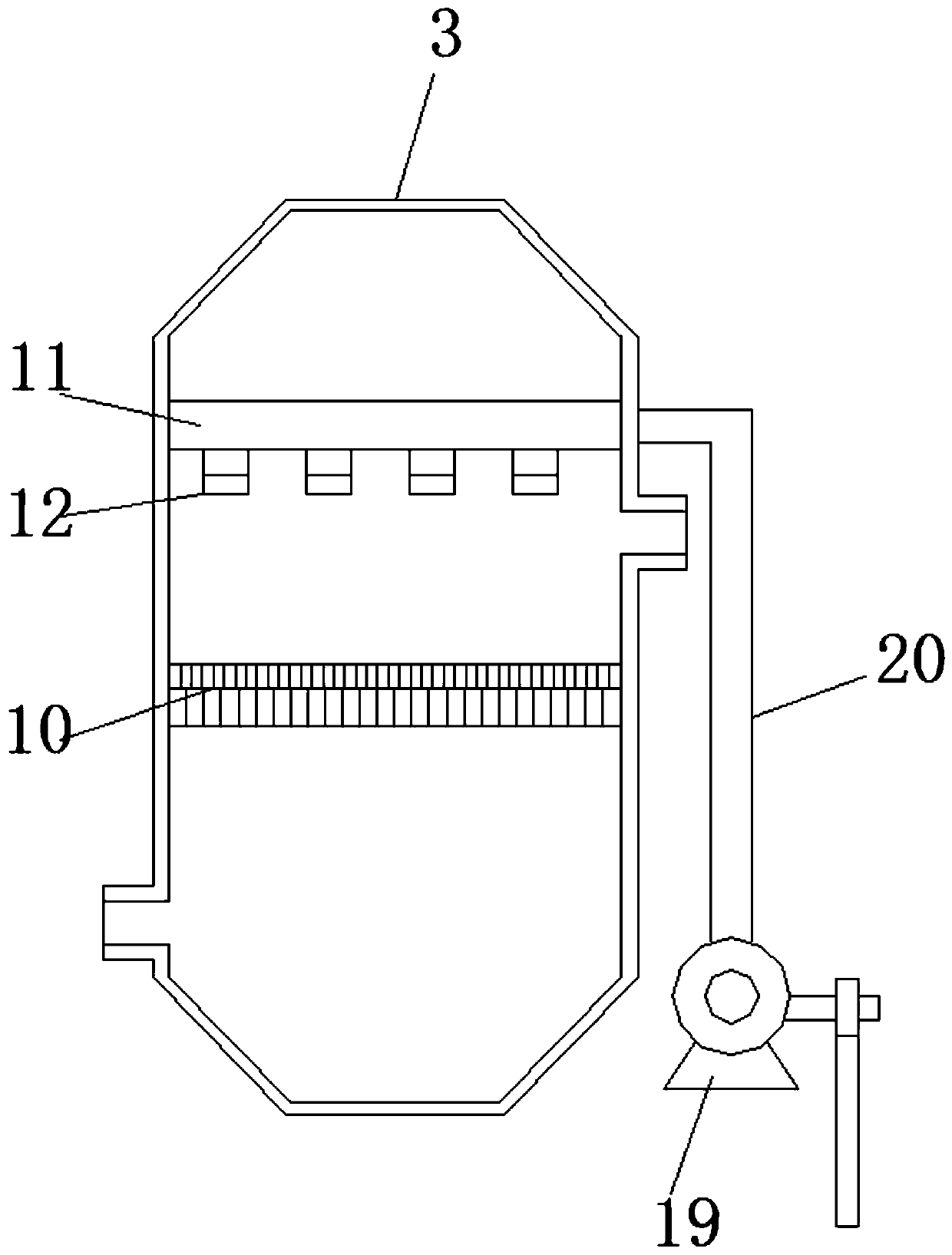

[0024] according to figure 1 , 2 , 3, 4, and 5, the present embodiment provides a coal-fired boiler flue gas efficient desulfurization and dust removal purification system for steam production, including a gravity settling chamber 1, a filter dust removal tower 2, a water bath dust removal tower 3, a desulfurization tower 4 and Settling filter tank 5, the inner wall of the gravity settling chamber 1 is provided with ash baffles 6, and the ash baffles 6 are staggered and arranged in multiple groups;

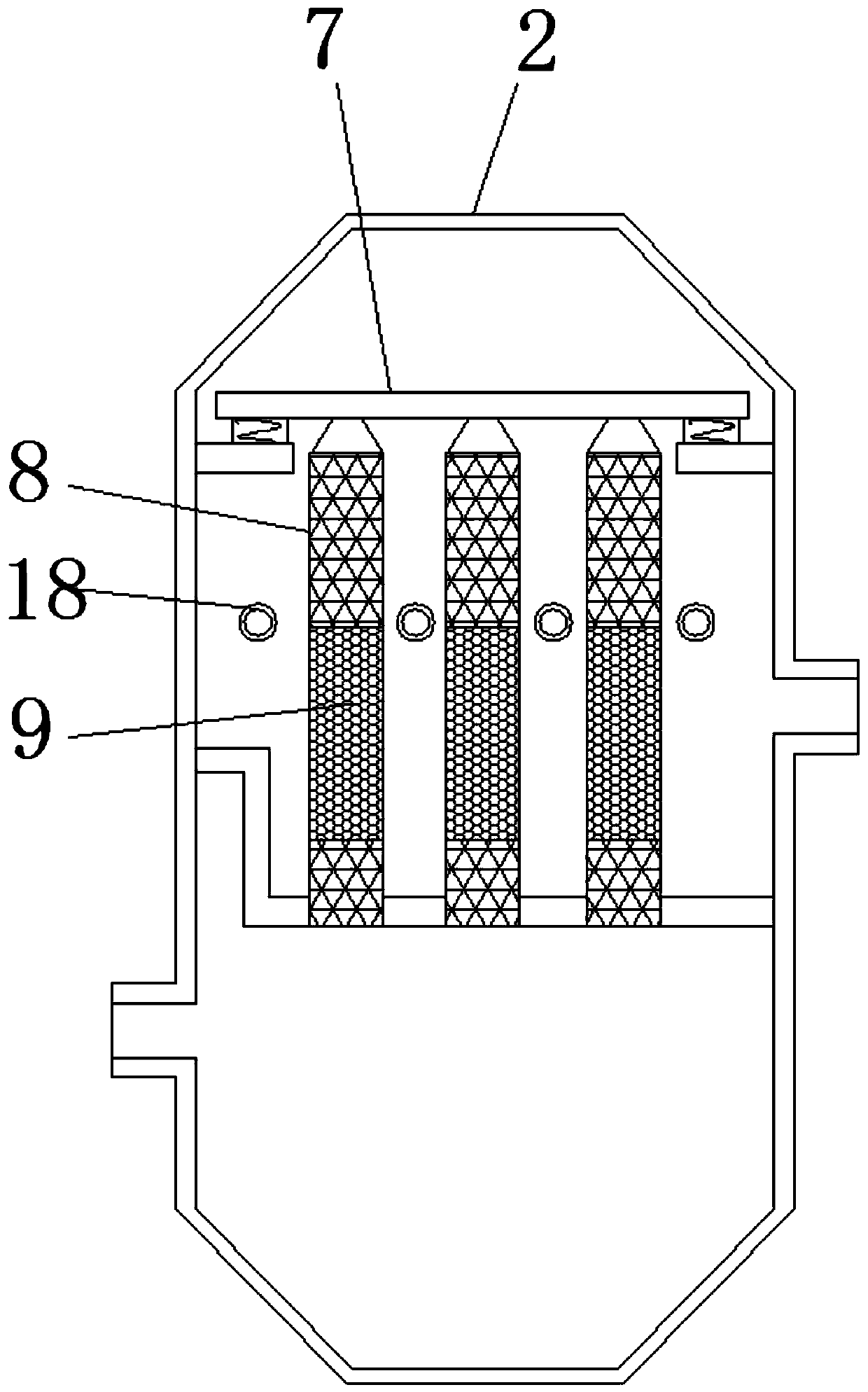

[0025] The interior of the filter and dedusting tower 2 is provided with a filter cavity, and a mounting plate 7 is installed softly above the filter cavity, and a dust removal bag 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com