Low-altitude electrostatic oil fume purifier and purification method thereof

An oil fume purifier, electrostatic technology, applied in chemical instruments and methods, external electrostatic separators, electrostatic separation, etc., can solve the problems of no effective treatment of oil fume pollution, small removal of oil fume pollutants, and high density of oil fume emissions. Achieve the effects of reducing equipment fire hazards, prolonging the use and maintenance cycle, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

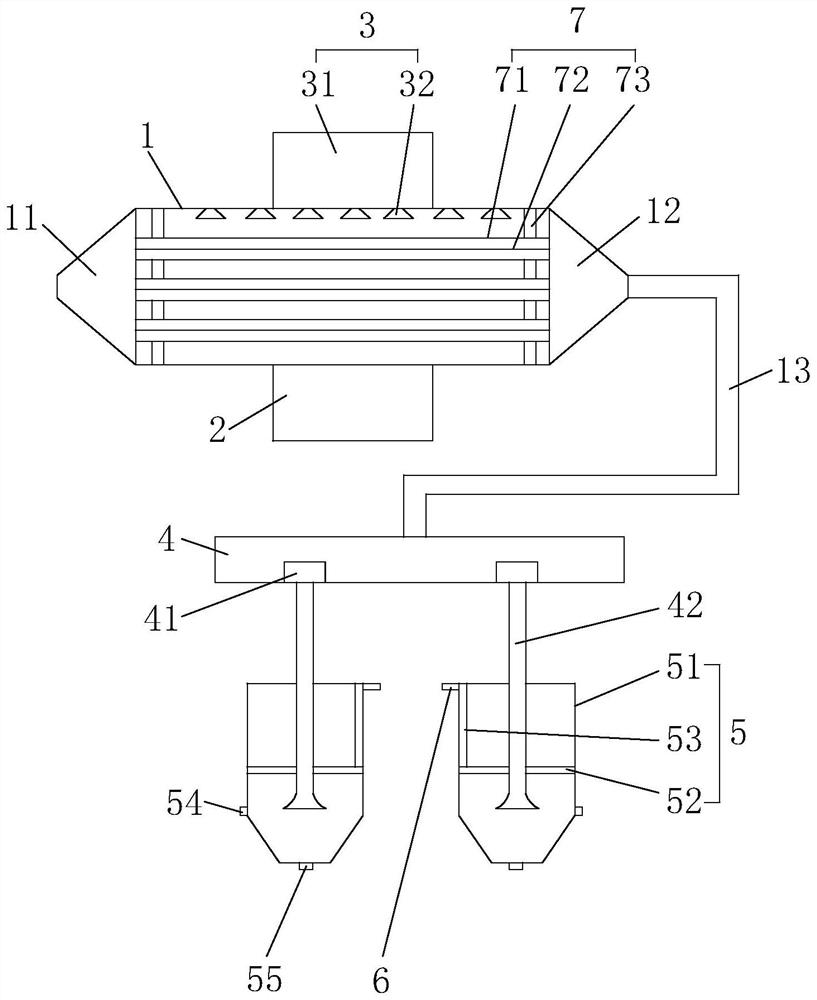

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0043] refer to figure 1 , is a low-altitude electrostatic oil fume purifier disclosed in the present invention, including a wet electrostatic purification system and an adsorption purification mechanism connected to the wet electrostatic purification system. The control electric box 2 and the fire extinguishing system 3 are provided with a DC high-voltage power supply in the control electric box 2, and a cylindrical honeycomb electric field 7 electrically connected to the DC high-voltage power supply is provided in the housing 1 .

[0044] The adsorption and purification mechanism includes a smoke collection hood 4 and a plurality of filter units 5 connected to the smoke collection hood 4. A plurality of range fume motors 41 are arranged in the smoke collection hood 4. The bottom of the range fume motor 41 is connected with a filter pipe 42. The filter unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com