Cleaning device for return rubber belt of belt conveyor

A belt conveyor and cleaning device technology, applied in the direction of conveyors, cleaning devices, conveyor objects, etc., can solve problems such as unsatisfactory results, polluting the site environment, and high treatment costs, so as to reduce belt deviation and achieve good cleaning effects , The effect of convenient operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Further description will be made below in conjunction with specific embodiments.

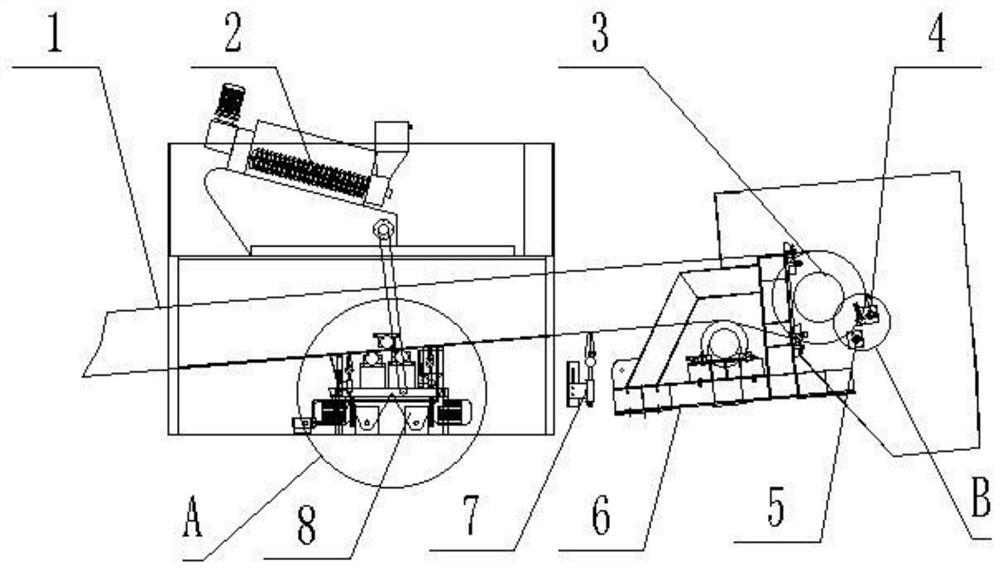

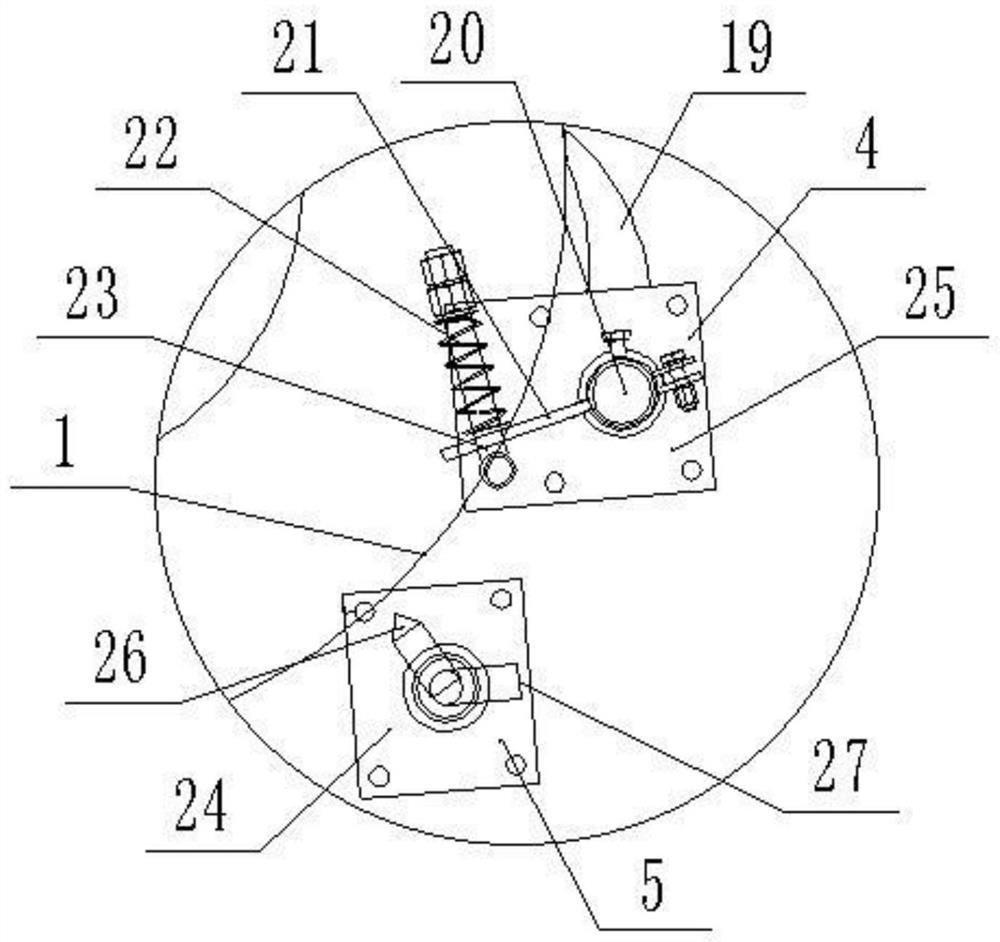

[0040] A belt conveyor return belt cleaning device, comprising: a cleaning device 4, a wet belt cleaning part 8 and a feed bin 29, and the discharge drum 3 of the belt conveyor is fixed with the feed bin 29 for receiving and unloading, so The first cleaning device 4 is installed at the discharge drum 3, the cleaning device 4 is used to clean the material remaining on the surface of the belt 1 and falls into the silo 29, and the return section of the belt 1 is equipped with a further cleaning device. Said wet belt cleaning means 8 for belt 1 residual material;

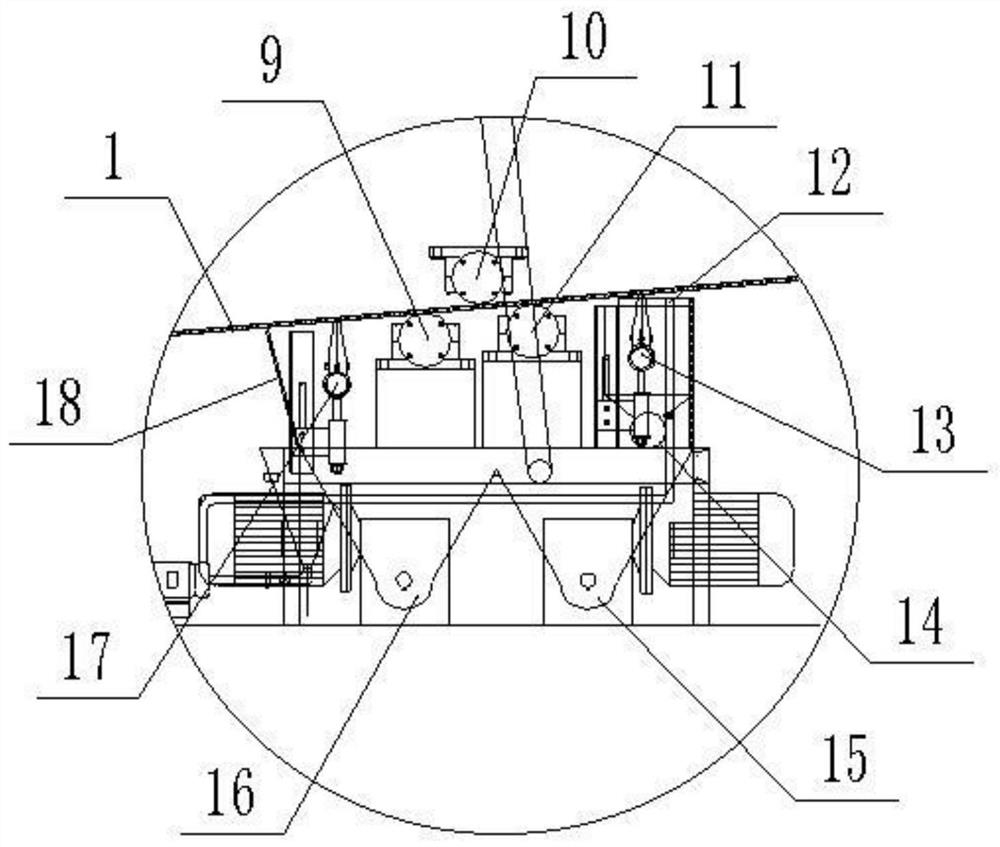

[0041] Described wet belt cleaning part 8 comprises: spray pipe 12, three road cleaners 13, drum group and No. 4 cleaner 17, described spray pipe 12, three road cleaners 13, roller group and No. 4 cleaner 17 It is arranged in sequence along the running direction of the return section of the belt 1, and the spray pipe 12 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com