A swirl filter combined pyrolysis gas dedusting device and method with adjustable flow rate

A technology of cyclone filtration and dust removal device, which is applied in cyclone devices, devices whose axial directions of cyclone can be reversed, etc., can solve the problem of not taking into account the attenuation of centrifugal separation, unfavorable pyrolysis dust collection, increased pressure drop, etc. problem, to achieve the effect of promoting overall performance, short residence time and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

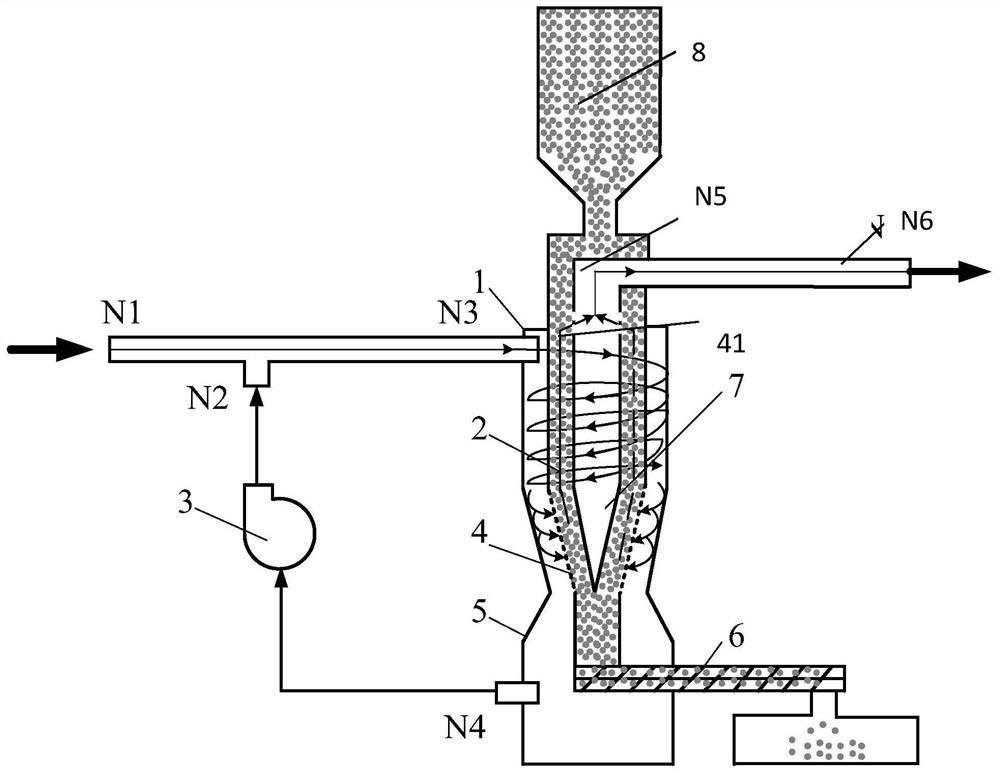

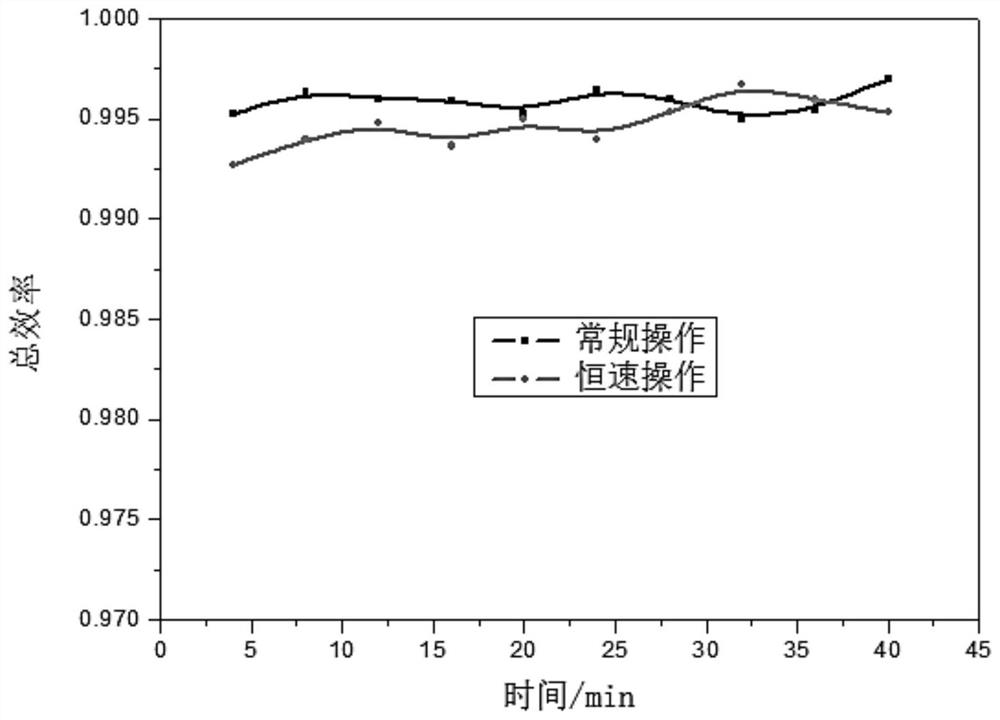

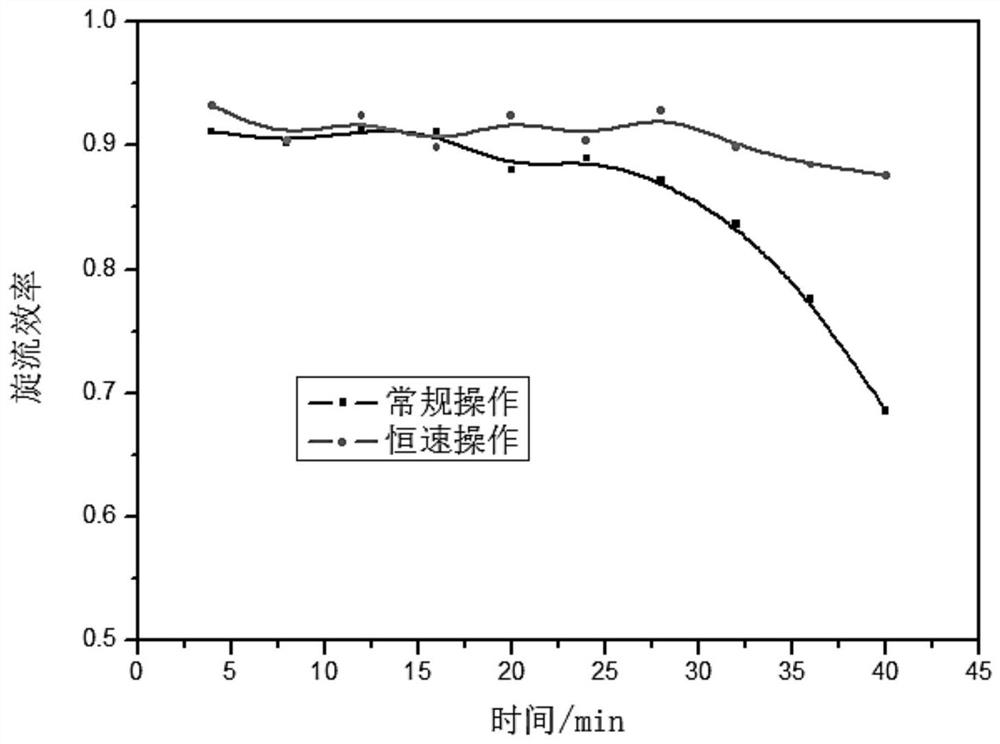

[0033] This embodiment is a Φ200mm, 20mm×60mm direct-cut tangential air inlet tangential reverse cyclone separator, a Φ150mm particle bed filter and a vortex fan controlled by a frequency converter. Such as figure 1 , the inlet of the frequency conversion fan is connected with the tangential outlet of the circulating airflow of the bottom ash hopper to carry out the pumping cycle, and the outlet of the frequency conversion fan is connected with the inlet of the dust-laden airflow. The test was carried out at room temperature, and the test device was operated with suction-type negative pressure. The gas is sucked in directly from the atmosphere, passed through a cyclone separator and a particle bed filter, and then evacuated by a fan. The swirling air velocity and filtering air velocity are measured by the Pitot tube on the pipeline. The dust concentration was measured at the outlet of the dust collector and the outlet of the bottom circulating airflow to calculate the total ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com