Rapid pipe joint mounting device and advanced small pipe construction method

An advanced technology of small conduits and pipe joints, which is applied in shaft equipment, earthwork drilling, wellbore lining, etc., can solve the problems of slurry leakage, complicated operation, increased workload, etc., and achieve safe and reliable process operation, firm and reliable connection, and avoid The effect of wasting resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

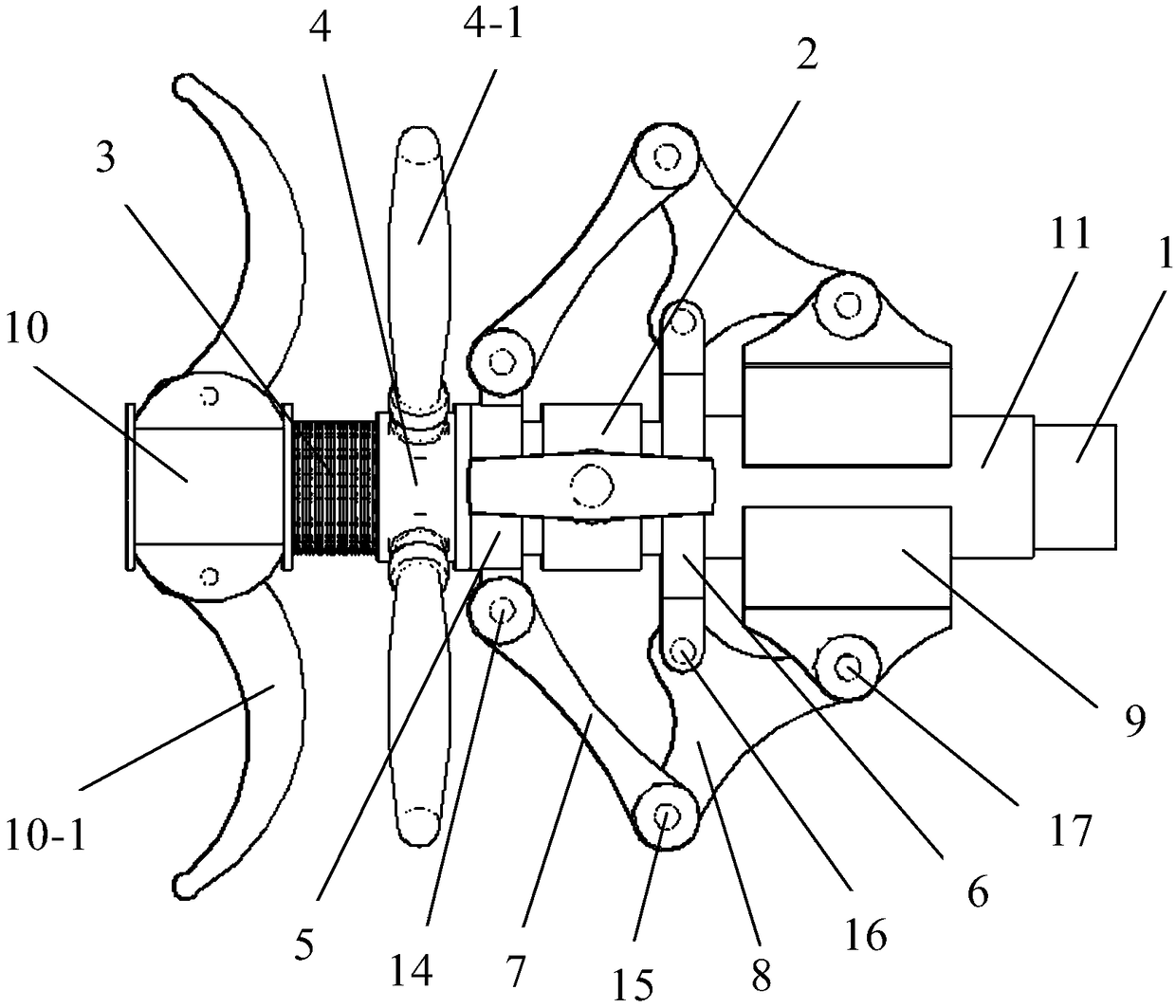

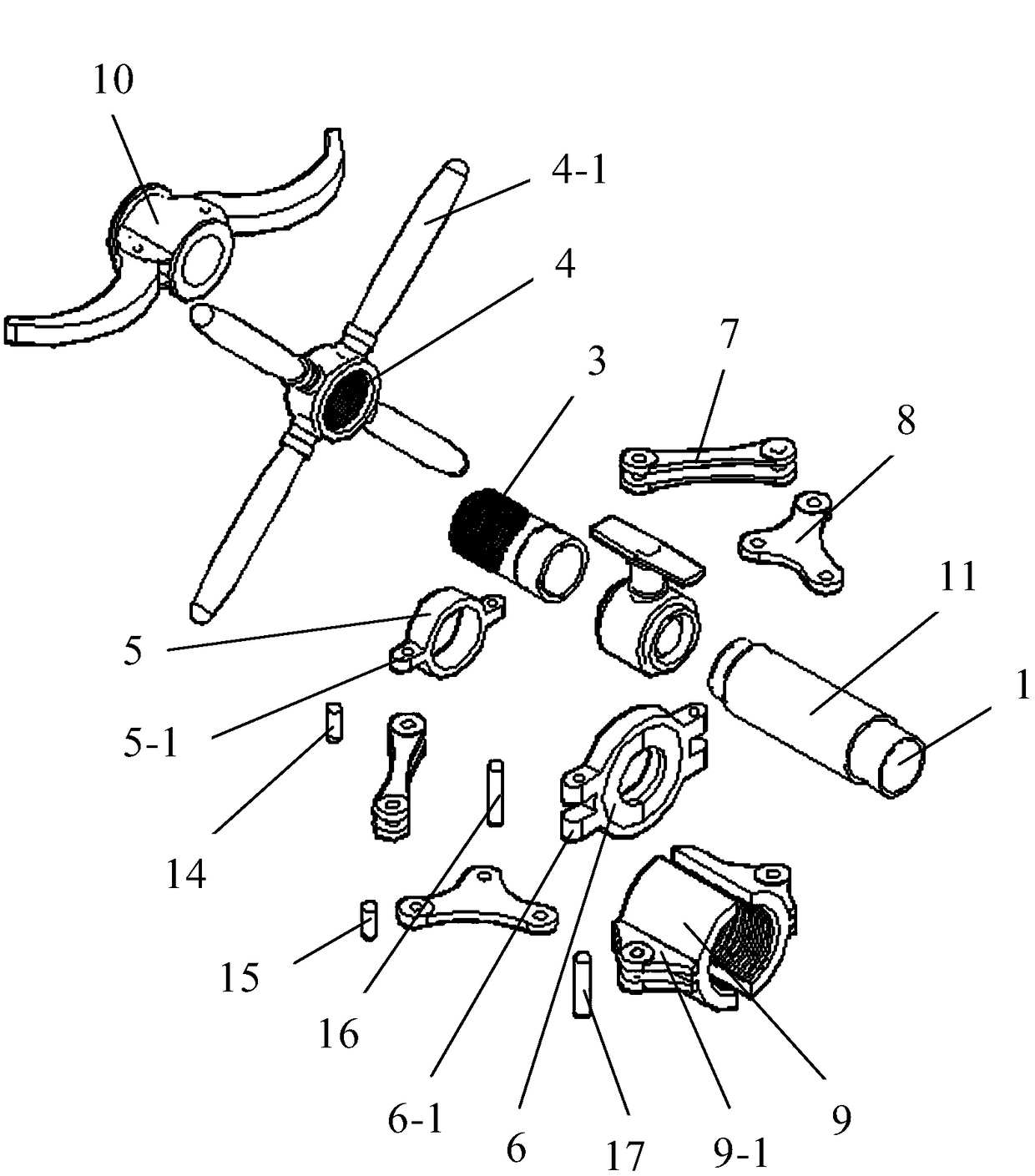

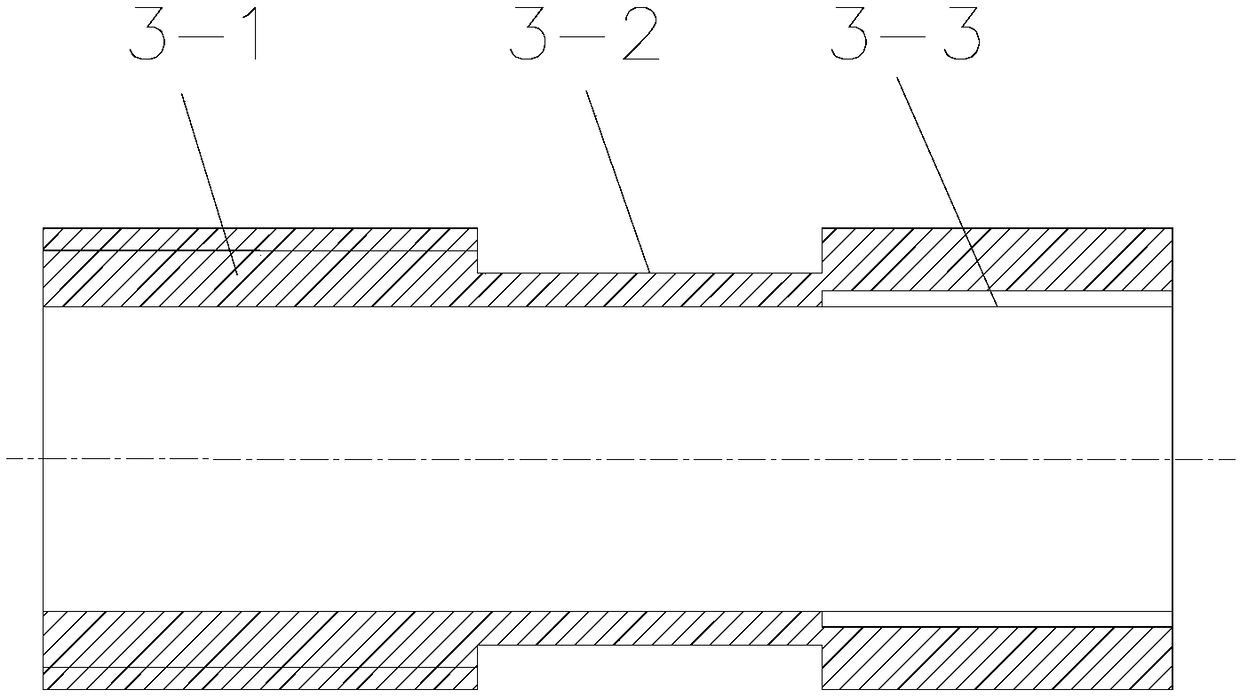

[0046] Such as figure 1 with figure 2 As shown, the present invention includes a pipe joint body, a clamping mechanism arranged on the pipe joint body and a quick joint 10 connected to the pipe joint body. The pipe joint body consists of a front end pipe 1, a slurry stop valve 2 and The rear end pipes 3 are connected sequentially, and the clamping mechanism includes at least two interlocking jaws 9, and a pusher set on the rear end pipe 3 to drive at least two jaws 9 to open and close. The pipe 4 and the connecting rod transmission assembly arranged between the push pipe 4 and each of the claws 9, the push pipe 4 is threadedly fitted with the rear end pipe 3, and the front end pipe 1 is fitted There is a rubber sealing tube 11, and the connecting rod transmission assembly includes a first sliding tube 5 set on the rear end tube 3, a second sliding tube 6 set on the front end tube 1, and a second sliding tube 6 set on the first The linear connecting rod 7 on the sliding tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com