Safe and environment-friendly oil refining technology achieving cracking recycling of waste organic matter by means of continuous feeding and slag discharging

A safe, environmentally friendly and organic technology, applied in solid waste removal, petroleum industry, recycling technology, etc., can solve problems such as accelerated scrapping, prone to accidents, unsafety, etc., and achieve improved production efficiency, good heat transfer effect, and good The effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

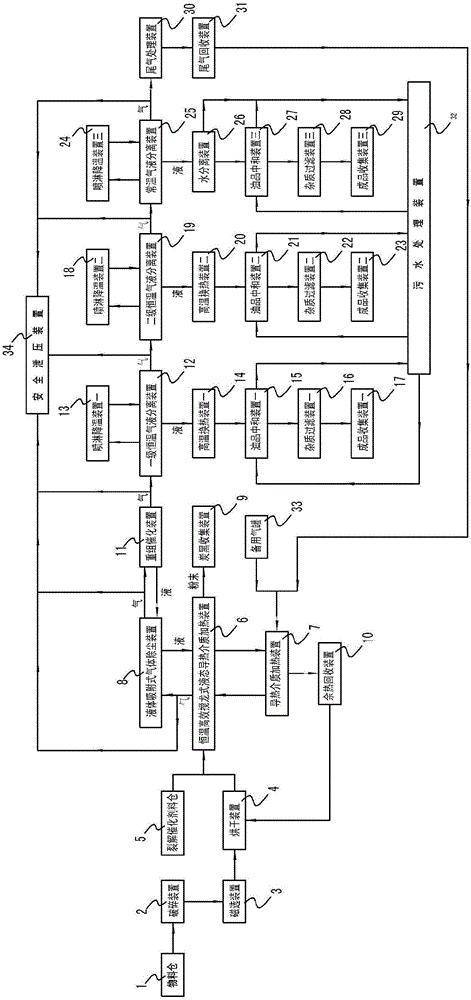

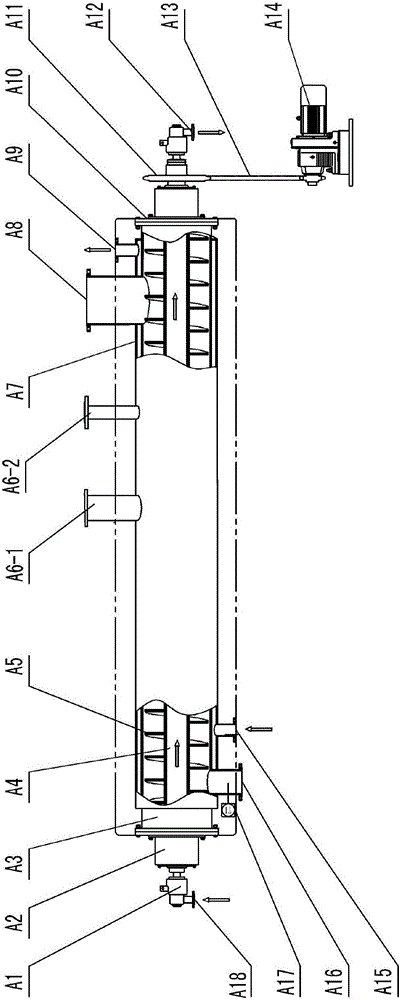

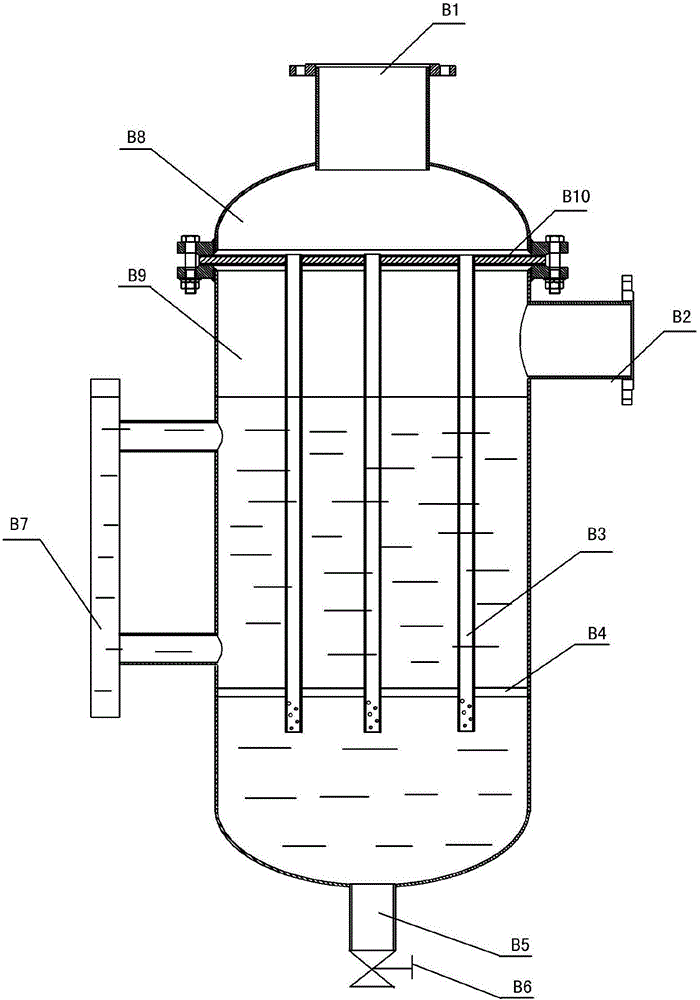

[0033] In this example, if figure 1As shown, a safe and environment-friendly oil refining device for continuous feeding, slagging waste organic matter cracking and recycling includes: material bin 1, crushing device 2, magnetic separation device 3, drying device 4, cracking catalyst bin 5, constant temperature and high-efficiency stirring Dragon-type liquid heat transfer medium heating device 6, heat transfer medium heating device 7, liquid adsorption gas dedusting device 8, carbon black collection device 9, waste heat recovery device 10, catalytic recombination device 11, primary constant temperature gas-liquid separation device 12, spray Device one 13, high temperature heat exchange device one 14, oil neutralization device one 15, impurity filter device one 16, finished product collection device one 17, spray device two 18, secondary constant temperature gas-liquid separation device 19, high temperature heat exchange device Two 20, oil neutralization device two 21, impurity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com