Manufacturing method and production line of composite panels

A composite board and production line technology, which is applied in the direction of manufacturing tools, other plywood/plywood appliances, wood processing appliances, etc., can solve the problems of non-green environmental protection household materials, high formaldehyde emission from particleboard, and large amount of mixed glue from particleboard, etc. Improve the bonding strength and production efficiency, shorten the hot pressing cycle, and facilitate the effect of the veneer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

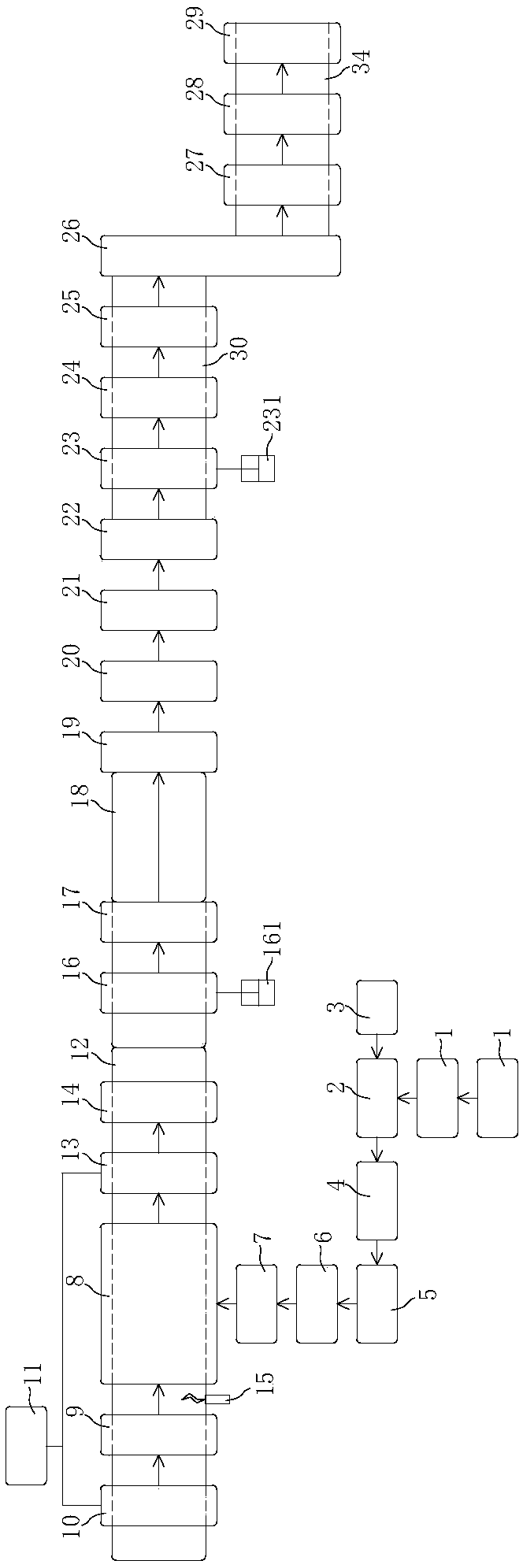

[0047] Such as figure 1 As shown, the present embodiment provides a production line for composite panels, including the lower surface layer paving station 10, the first pre-pressing station 9, the bonding station 8, the upper surface layer paving station 13, the first Two pre-pressing stations 14 and hot-pressing stations 21; also include conveying devices to convey materials to each station; conveying devices in the present embodiment include downward surface layer paving stations 10, the first pre-pressing stations 9, The bonding station 8, the upper surface layer paving station 13 and the first conveyor 12 for conveying materials at the second pre-pressing station 14; the bonding station 8 is provided with two material inlets, and the bonding station 8 One of the two material inlets is connected to the material outlet of the first pre-pressing station 9 , and the other material inlet is provided with a gluing station 6 . Specifically, a paving machine is provided at the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com