Marigold lutein supercritical CO2 extraction method

A supercritical, marigold technology, applied in the fields of medicine, health food processing and application, and food, to achieve the effects of strong selectivity, improved yield and good development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

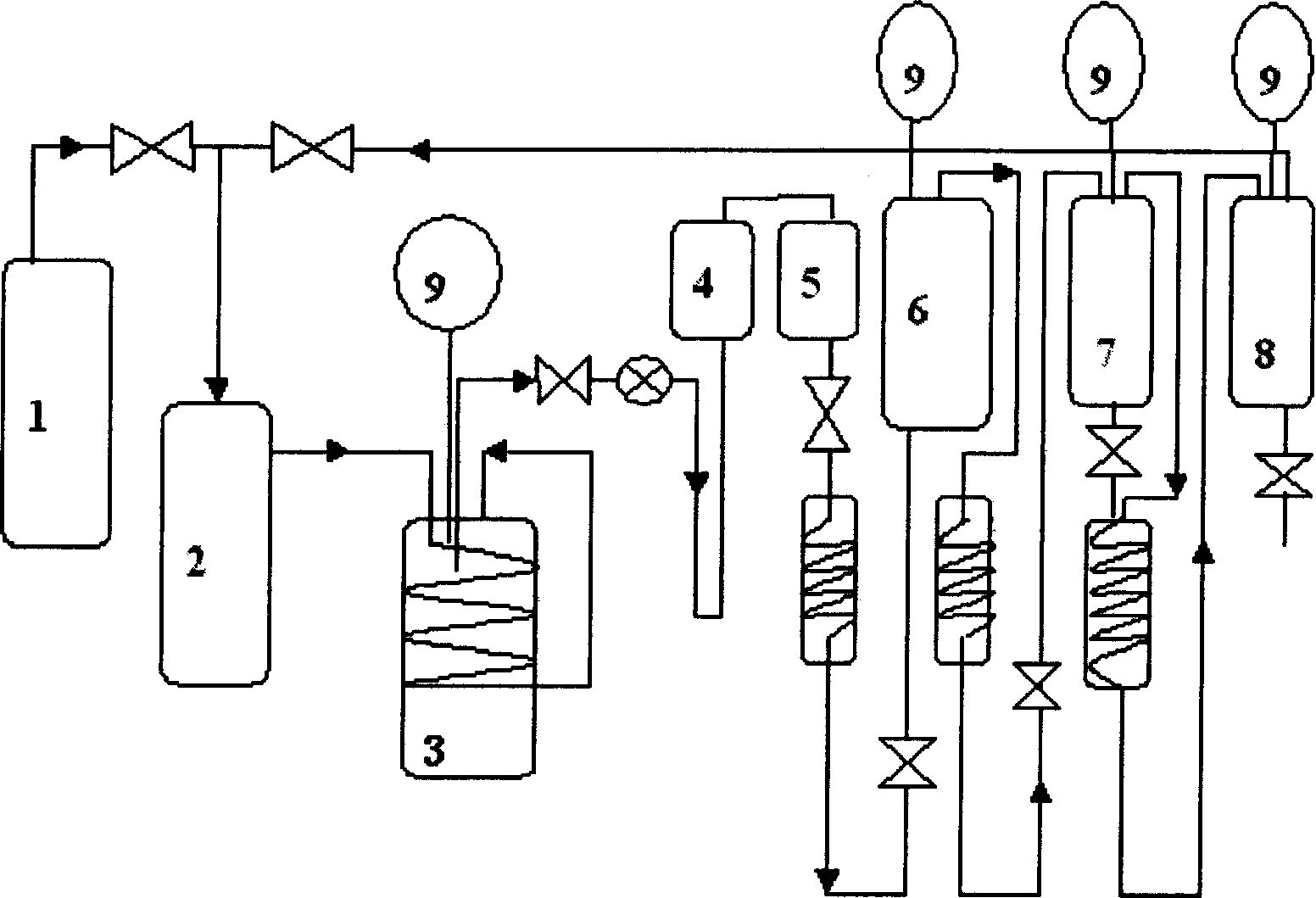

Image

Examples

Embodiment 1

[0026] 1. After the fermented and granulated marigold granules are dried at room temperature, they are pulverized by a pulverizer.

[0027] 2. Put 200 g of crushed marigold raw materials into the extractor, use supercritical carbon dioxide with a purity of 99%, extract at 40°C at an extraction temperature of 35 MPa, and CO 2 Extract for 11 hours under the condition of flow rate 10L / h, separation I temperature 45°C, separation pressure 10MPa, separation II temperature 25°C, same pressure as the storage tank, and a total of 19.0g marigold oleoresin was obtained.

[0028] 3. Measure the lutein content by the marigold oleoresin obtained from the separation I by the FAO method, and calculate that the lutein is 750.36 mg.

Embodiment 2

[0030] 1. After the fermented and granulated marigold granules are dried at room temperature, they are pulverized by a pulverizer.

[0031] 2. Put 200g of the pulverized marigold raw material into the extractor, use supercritical carbon dioxide with a purity of 99%, at a temperature of 50°C, a pressure of 30MPa, CO 2 Under the condition of flow rate 10L / h, extract for 11h, separation I temperature is 50°C, separation pressure is 12MPa, separation II temperature is 25°C, the pressure is the same as that of the storage tank, and a total of 20.2g of marigold oleoresin is separated.

[0032] 3. Measure the lutein content by the marigold oleoresin obtained from the separation I by the FAO method, and calculate that the lutein is 1023.56 mg.

Embodiment 3

[0034] 1. After the fermented and granulated marigold granules are dried at room temperature, they are pulverized by a pulverizer.

[0035] 2. Put 200g of the pulverized marigold raw material into the extractor, use supercritical carbon dioxide with a purity of 99%, at a temperature of 45°C, a pressure of 35MPa, CO 2 Extracted for 9 hours under the condition of flow rate 15L / h, separation I temperature was 60°C, separation pressure was 10MPa, separation II temperature was 20°C, and the pressure was the same as that of the storage tank. A total of 18.776g of marigold oleoresin was isolated.

[0036] 3. Measure the lutein content by the marigold oleoresin obtained from the separation I by the FAO method, and calculate that the lutein is 836.23 mg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com