Method for preparing lignin nanoparticles by taking papermaking black liquid as raw material

A paper-making black liquor and nano-particle technology, which is applied in the field of lignin nano-particle preparation, can solve the problems of difficult to obtain, expensive ionic liquid, difficult to promote the application of nano-lignin, etc., to achieve easy to obtain, avoid oxidation, and good adsorption performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

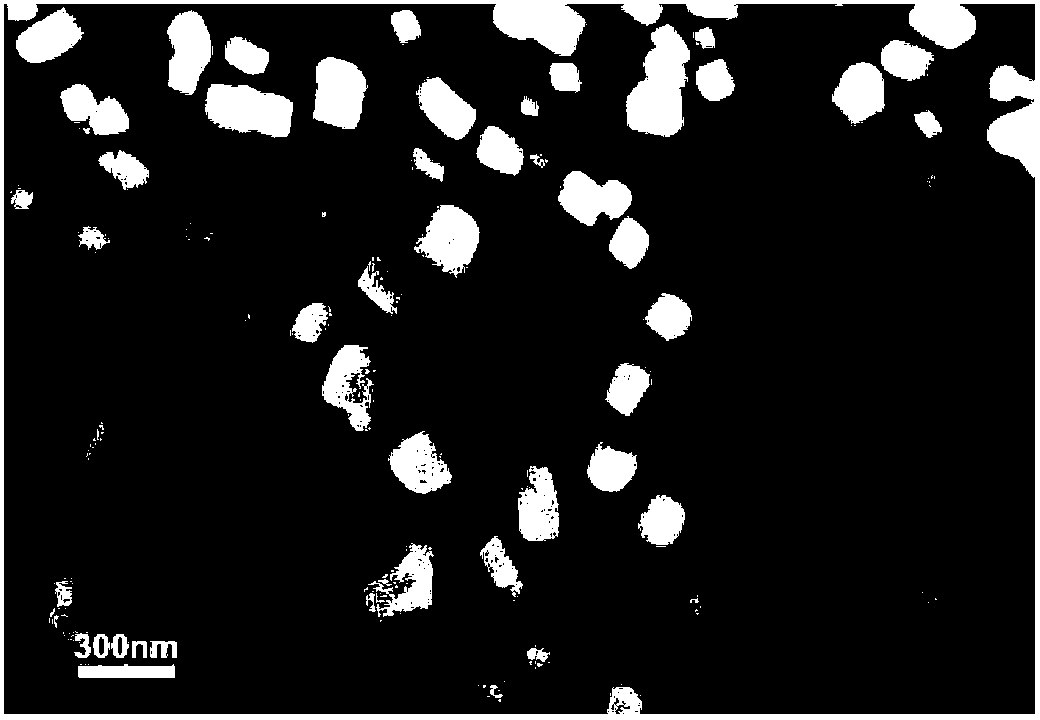

Embodiment 1

[0033] (1) Preparation of alkali lignin from papermaking black liquor:

[0034] (a) Take 100 parts of papermaking black liquor from Pumiao Paper Mill, heat it in a water bath to 50°C, add 10% sulfuric acid to pH=2.2~3.0 while stirring, and precipitate a large amount of alkali lignin, filter it, and rinse it repeatedly with distilled water until medium properties, dried under vacuum at 65°C for 12 hours, and ground to obtain soda ash lignin;

[0035] (b) Take 100 parts of papermaking black liquor and perform ultrafiltration with an ultrafiltration device. The molecular weight cut-off of the ultrafiltration membrane is 2,000 and 50,000 to remove a large amount of inorganic salts and low molecular weight organic substances in the black liquor. The obtained filtrate is heated at 65°C Dry under vacuum for 12 hours, and grind to obtain soda ash lignin.

[0036] (2) Preparation of lignin colloid:

[0037](a) Take 50 parts of the alkali lignin obtained in the above step (1), add 375...

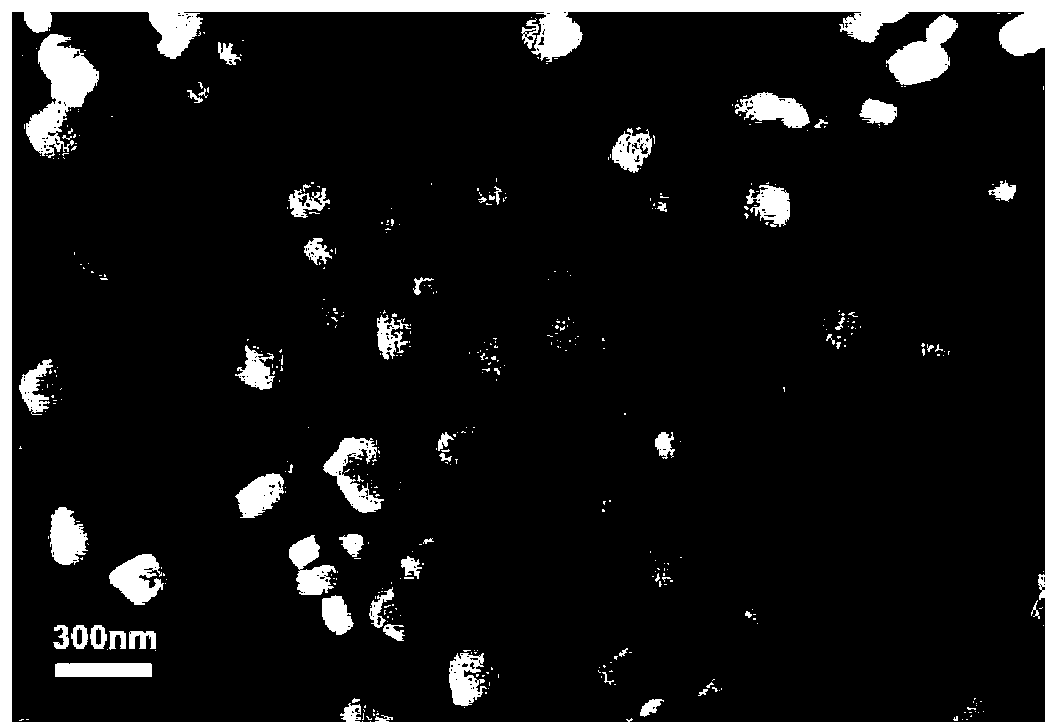

Embodiment 2

[0042] (1) Preparation of alkali lignin from papermaking black liquor:

[0043] (a) Take 100 parts of papermaking black liquor from Pumiao Paper Mill, heat it in a water bath to 60°C, add 10% sulfuric acid to pH=2.2~2.8 while stirring, and precipitate a large amount of alkali lignin, filter it, and rinse it repeatedly with distilled water until medium properties, dried under vacuum at 70°C for 11 hours, and ground to obtain soda ash lignin;

[0044] (b) Take 100 parts of papermaking black liquor and perform ultrafiltration with an ultrafiltration device. The molecular weight cut-off of the ultrafiltration membrane is 2,000 and 50,000 to remove a large amount of inorganic salts and low-molecular-weight organic substances in the black liquor. Dry under vacuum for 13 hours, and grind to obtain soda ash lignin.

[0045] (2) Preparation of lignin colloid:

[0046] (a) Take 50 parts of the alkali lignin obtained in the above step (1), add 400 parts of distilled water, keep stirrin...

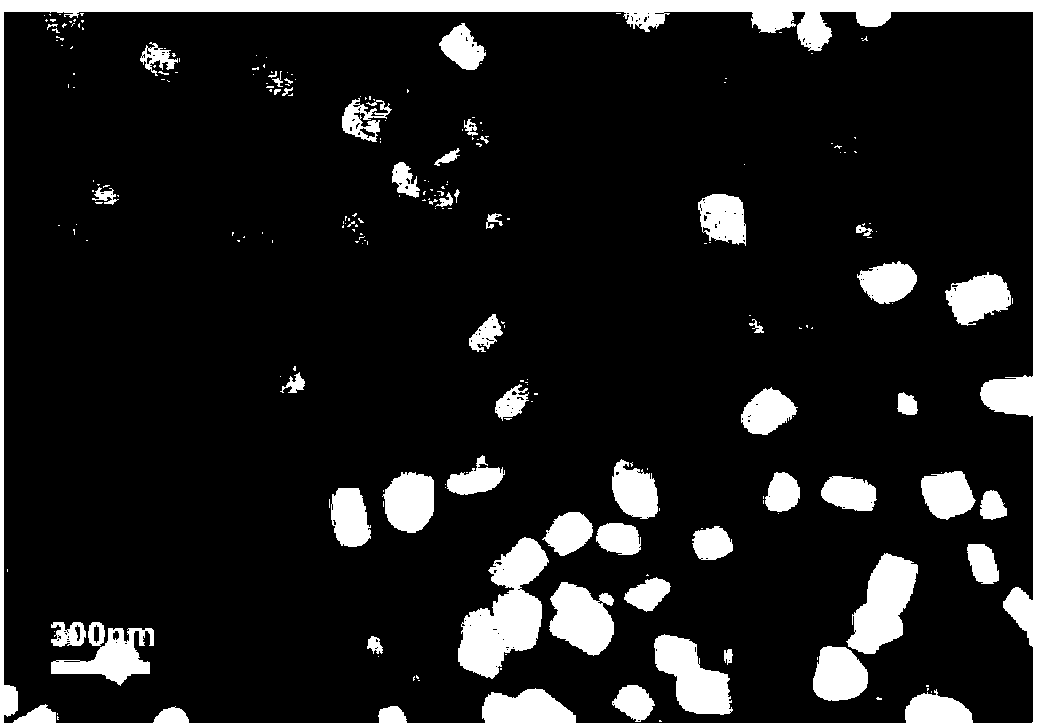

Embodiment 3

[0051] (1) Preparation of alkali lignin from papermaking black liquor:

[0052] (a) Take 100 parts of papermaking black liquor from Pumiao Paper Mill, heat it in a water bath to 55°C, add 10% sulfuric acid to pH=2.2~3.0 while stirring, and precipitate a large amount of alkali lignin, filter it, and rinse it repeatedly with distilled water until medium properties, dried under vacuum at 60°C for 13 hours, and ground to obtain soda ash lignin;

[0053] (b) Take 100 parts of papermaking black liquor and perform ultrafiltration with an ultrafiltration device. The molecular weight cut-off of the ultrafiltration membrane is 2,000 and 50,000 to remove a large amount of inorganic salts and low-molecular-weight organic substances in the black liquor. Dry under vacuum for 11 hours, and grind to obtain soda ash lignin.

[0054] (2) Preparation of lignin colloid:

[0055] (a) Take 50 parts of the alkali lignin obtained in the above step (1), add 350 parts of distilled water, keep stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com