Wall-breaking abstraction melissa powder oil and fat method with supercritical carbonic anhydride

A technology of carbon dioxide and bee pollen, which is applied in the fields of medicine and health care product processing, can solve problems such as high extraction pressure and temperature, broken pollen cell walls, complex process steps, etc., and achieves reduced blockage, simplified process, and strong selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

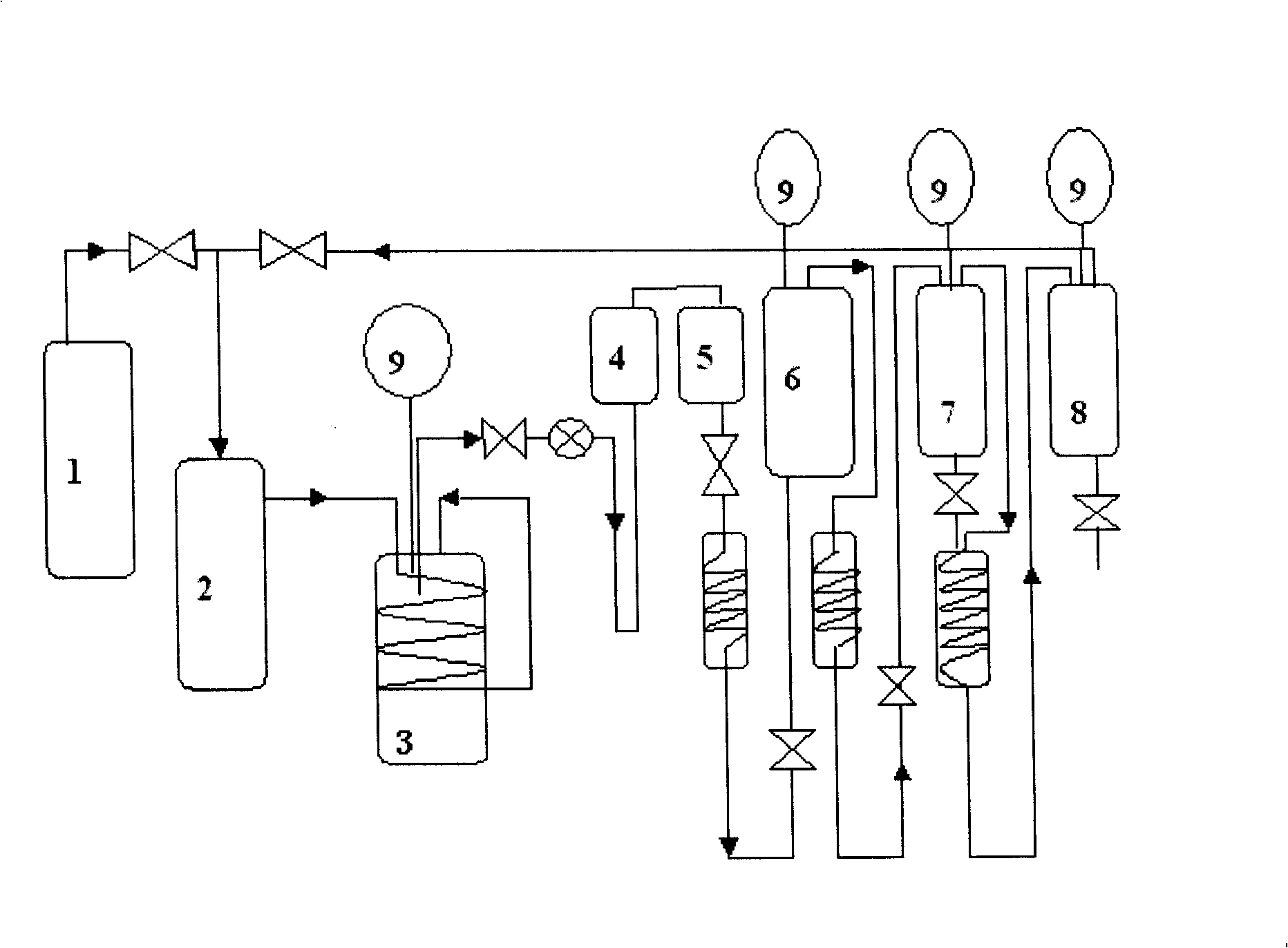

Method used

Image

Examples

Embodiment 1

[0017] Dry the bee pollen to a moisture content of 10.0%; then put 300g of the dried bee pollen into the extraction kettle, control the temperature of the extraction kettle at 35°C, use carbon dioxide with a purity of 99% to boost the pressure to 45MPa, hold the pressure for 10 minutes, and then open the exhaust The valve quickly empties the carbon dioxide, and continues to feed carbon dioxide into the extraction kettle. Extract for 2 hours under the conditions of extraction temperature 40°C, pressure 35MPa, carbon dioxide flow rate 10L / h, separation I temperature 45°C, separation pressure 10MPa, separation II temperature 40°C , the pressure is the same as that of the storage tank, and a total of 15.03g of bee pollen oil is obtained.

Embodiment 2

[0019] Dry the bee pollen to a moisture content of 10.0%; then put 300g of the dried bee pollen into the extraction kettle, control the temperature of the extraction kettle at 40°C, use carbon dioxide with a purity of 99% to boost the pressure to 30MPa, hold the pressure for 10 minutes, and then open the exhaust The valve quickly empties the carbon dioxide, and continues to feed carbon dioxide into the extraction kettle, extract for 1 hour under the conditions of extraction temperature 50°C, pressure 30MPa, carbon dioxide flow rate 15L / h, separation I temperature 45°C, separation pressure 8MPa, separation II temperature 40°C , the pressure is the same as that of the storage tank, and a total of 14.63g of bee pollen oil is obtained.

Embodiment 3

[0021] Dry the bee pollen to a moisture content of 10.0%; then put 300g of the dried bee pollen into the extraction kettle, control the temperature of the extraction kettle at 45°C, use carbon dioxide with a purity of 99% to boost the pressure to 45MPa, hold the pressure for 10 minutes, and then open the exhaust The valve quickly empties the carbon dioxide, continues to feed carbon dioxide into the extraction kettle, extracts for 2 hours under the conditions of extraction temperature 60°C, pressure 20MPa, carbon dioxide flow rate 20L / h, separation I temperature 60°C, separation pressure 10MPa, separation II temperature 40°C , the pressure is the same as that of the storage tank, and a total of 15.80g of bee pollen oil is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com