Arc start control method for AC arc welding

A technology of AC arc and control method, which is applied in the direction of arc welding equipment, welding equipment, manufacturing tools, etc., and can solve problems such as time-consuming, arc breaking, and easy arc breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, various embodiments of the present invention will be described with reference to the drawings.

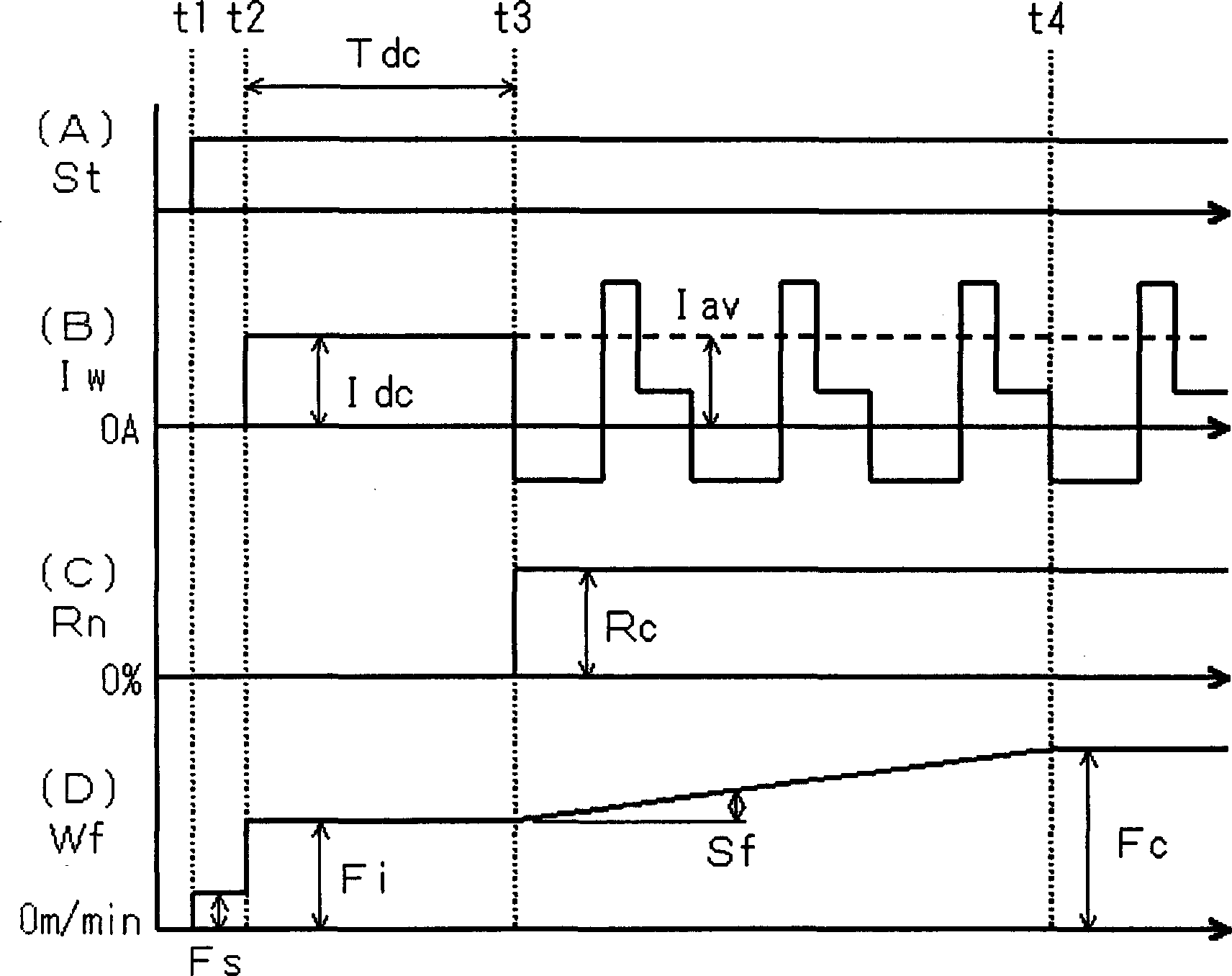

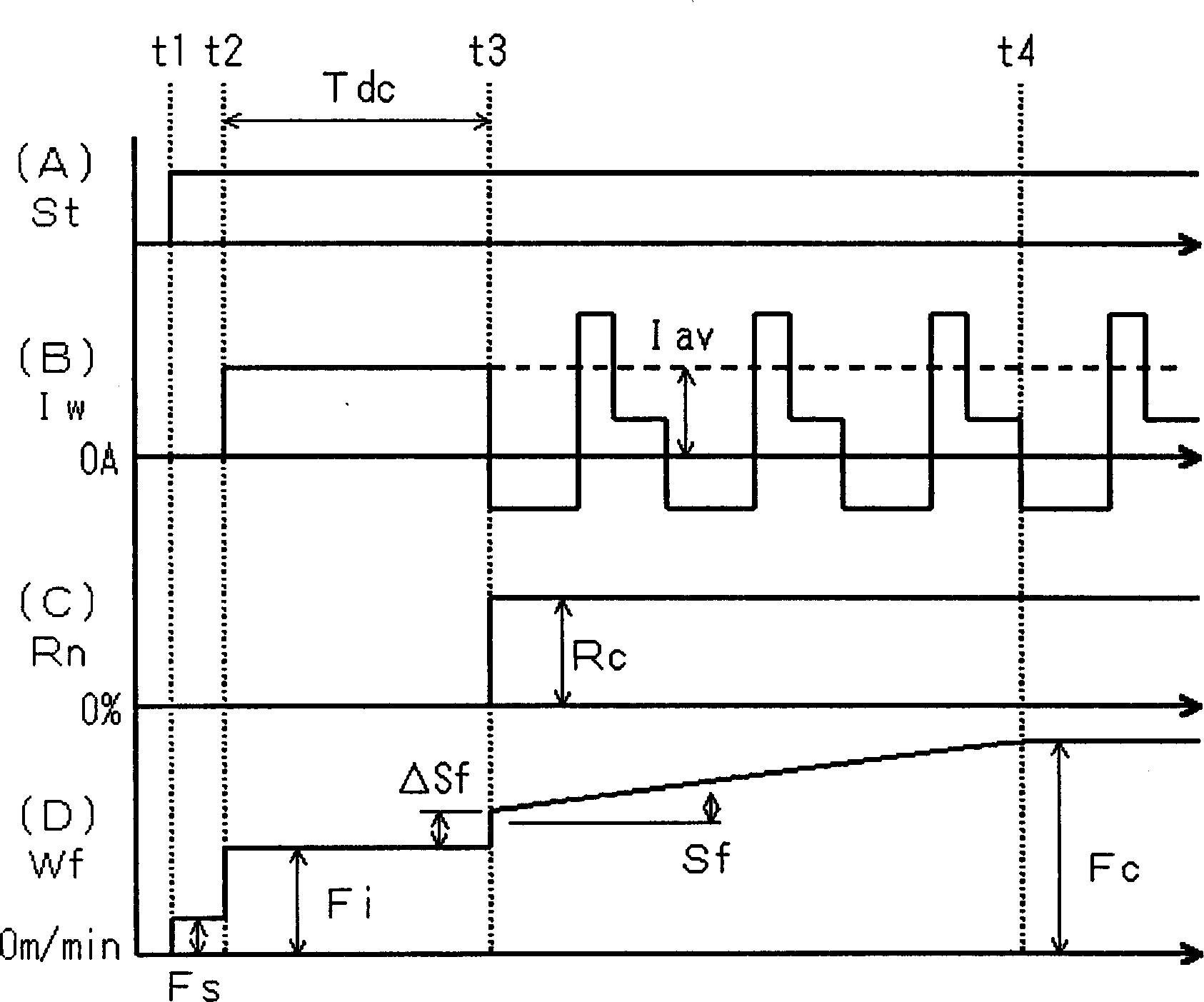

[0039] figure 1 It is a waveform diagram showing the arc ignition control method of AC arc welding according to the embodiment of the present invention. The figure (A) shows the time change of the welding start signal St, the figure (B) shows the time change of the welding current Iw, the figure (C) shows the time change of the electrode negative polarity ratio Rn, and the figure (D) shows the wire feeding speed of the welding wire Time variation of Wf. Hereinafter, description will be made with reference to this figure.

[0040] At time t1, when the welding start signal St is at a high level as shown in (A), the welding wire is fed to the base metal at a slow decelerated wire-feeding speed Fs as shown in (D). At time t2, when the leading end of the welding wire reaches and touches the base material, the welding wire is switched to the initial wire feeding s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com