Particulate filler mattress

a filler mattress and mattress technology, applied in the field of mattresses, can solve the problems of user fatigue, soreness and limited rest, stiffness of users of mattresses, and weight of liquid filler, etc., and achieve the effects of less weight, easy lifting, maneuvering, moving and otherwise transporting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

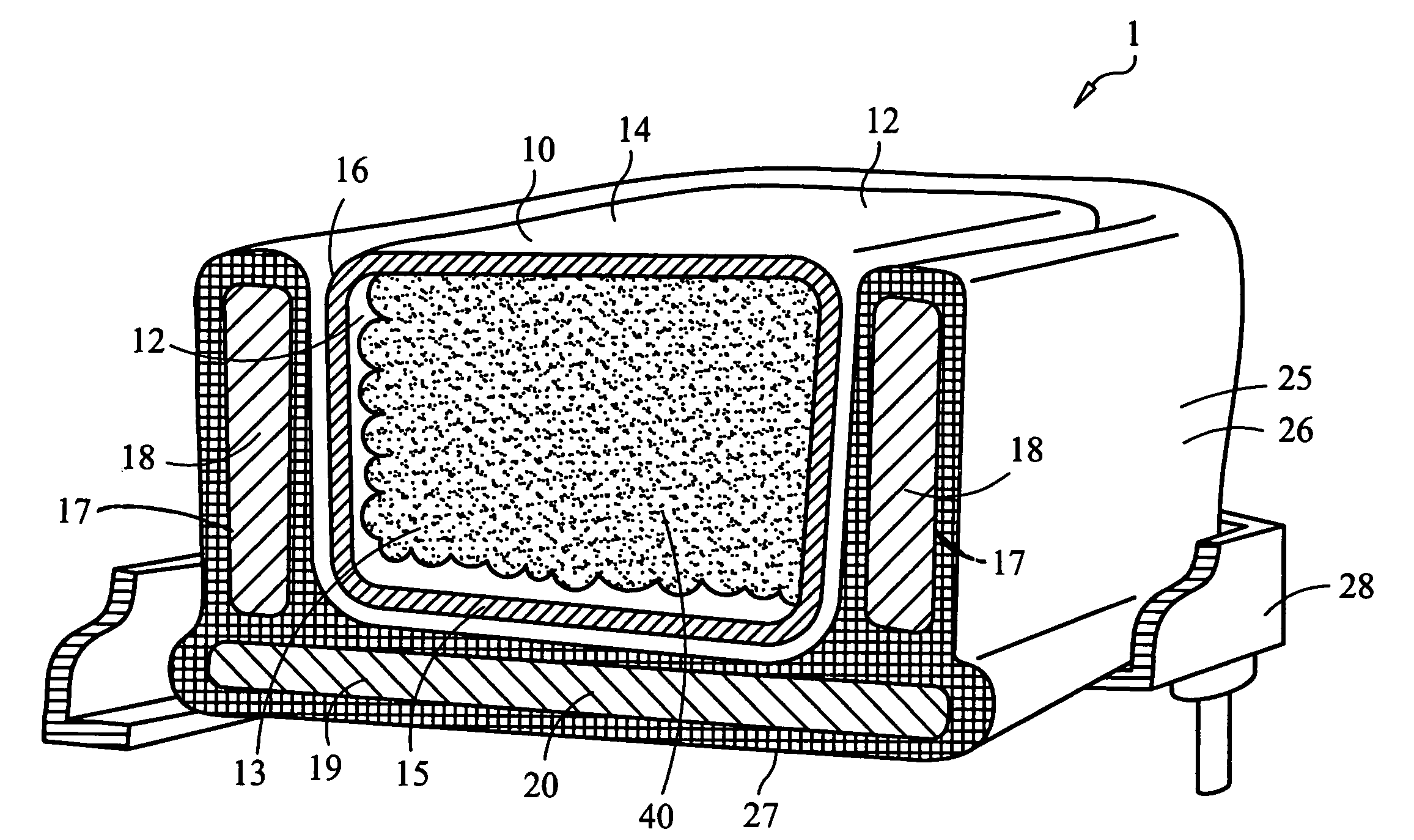

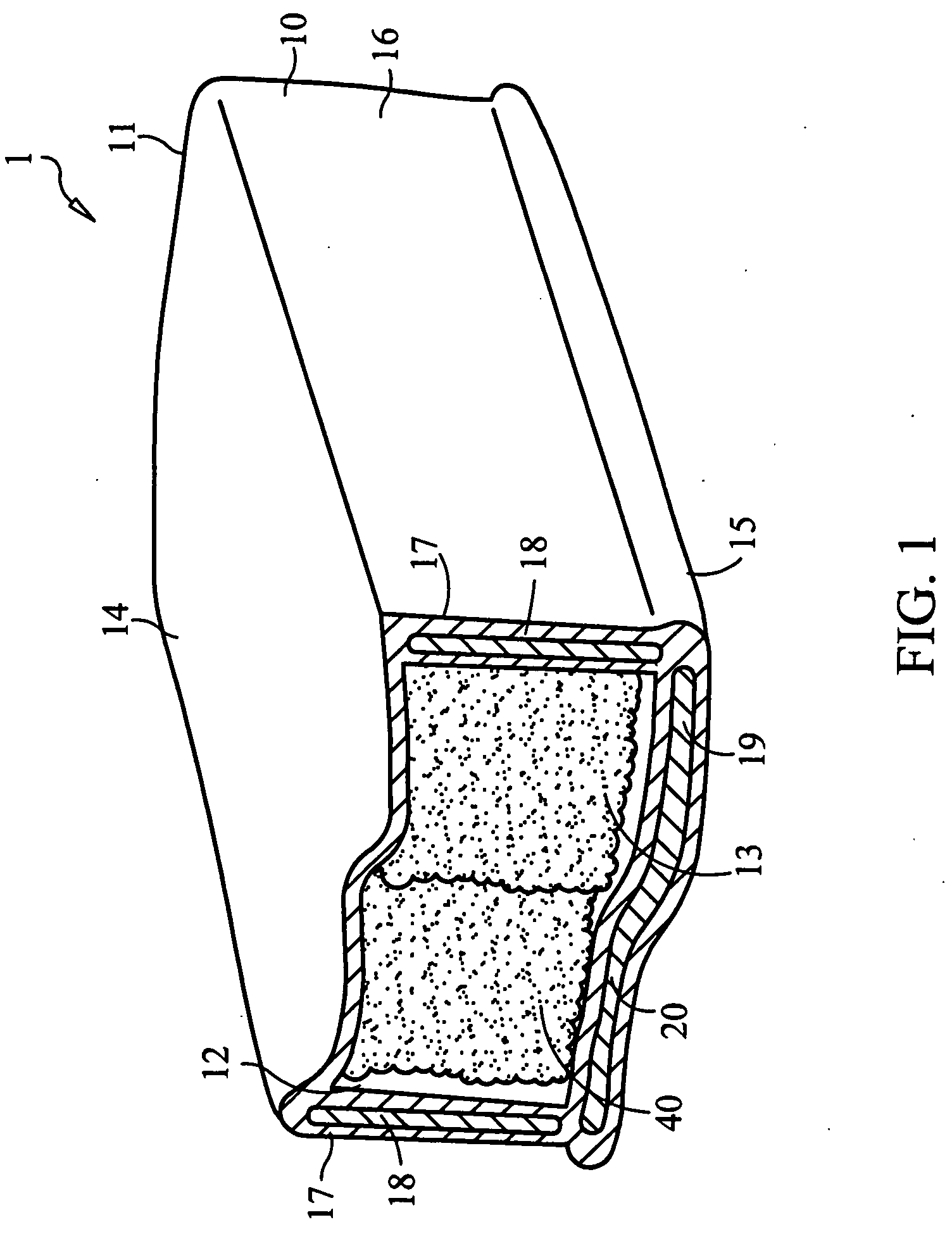

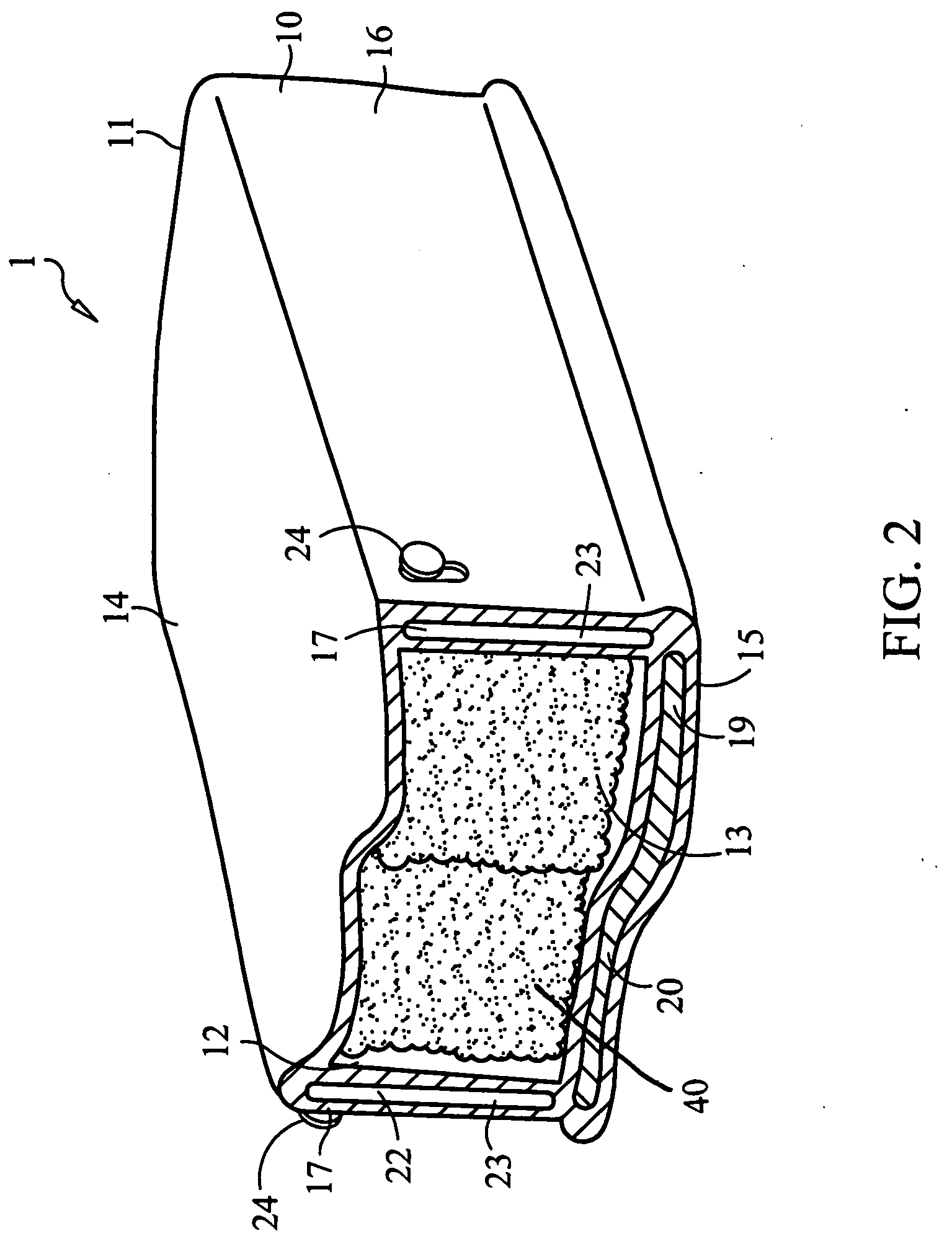

Image

Examples

Embodiment Construction

[0011] Advantages of One or More Embodiments of the Present Invention

[0012] The various embodiments of the present invention may, but do not necessarily, achieve one or more of the following advantages:

[0013] the ability to reduce foam sheet waste by the foam manufacturers;

[0014] provide a comfort, form fitting and support of a fluid based mattress without the weight and possibility of leakage damage that may be found with a fluid base mattress;

[0015] provide a non-fluid based mattress with the comfort, form fitting and support of a fluid-based mattress;

[0016] provide a mattress which could provide comfort levels that meet or exceed traditional spring- based mattresses with less weight, and bulk of spring-based mattresses;

[0017] provide a mattress that has waterbed type support and comfort that is easily transportable;

[0018] provide a mattress that has waterbed type support and comfort without the usage of liquid filler;

[0019] provide a mattress that is easier to lift, maneu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com