Hollow desktop board and its hollow blow molding process

A desktop board and hollow technology, applied to tables, furniture parts, household appliances, etc., can solve problems such as poor hollow blow molding process, poor structural design, poor strength, and poor load-carrying weight, so as to achieve feasible process and low production cost , good firmness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

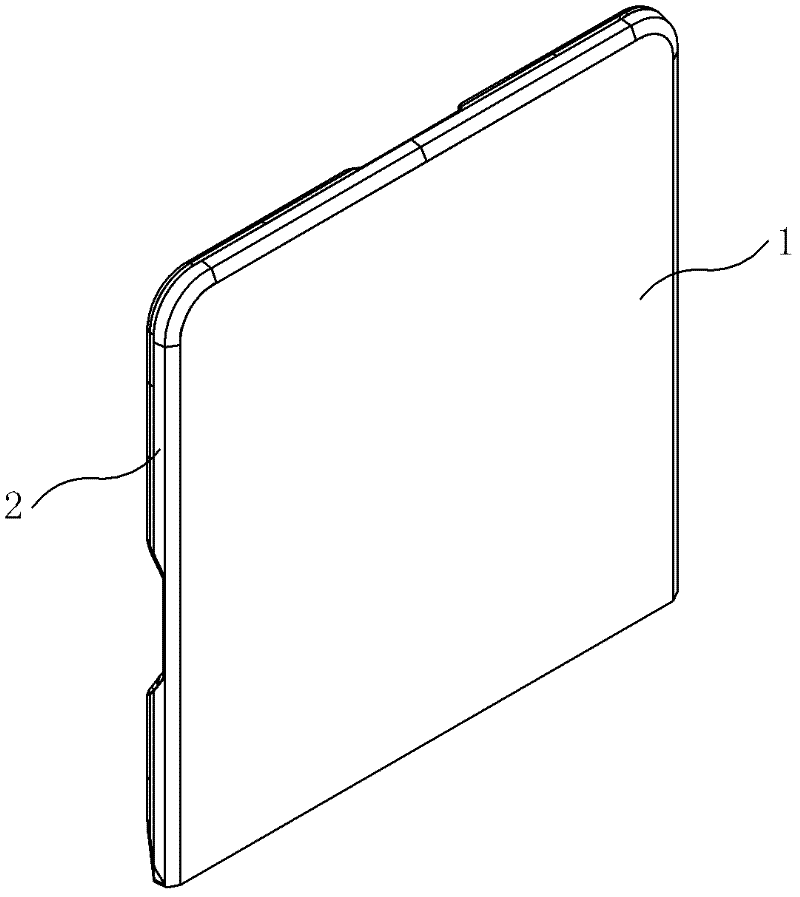

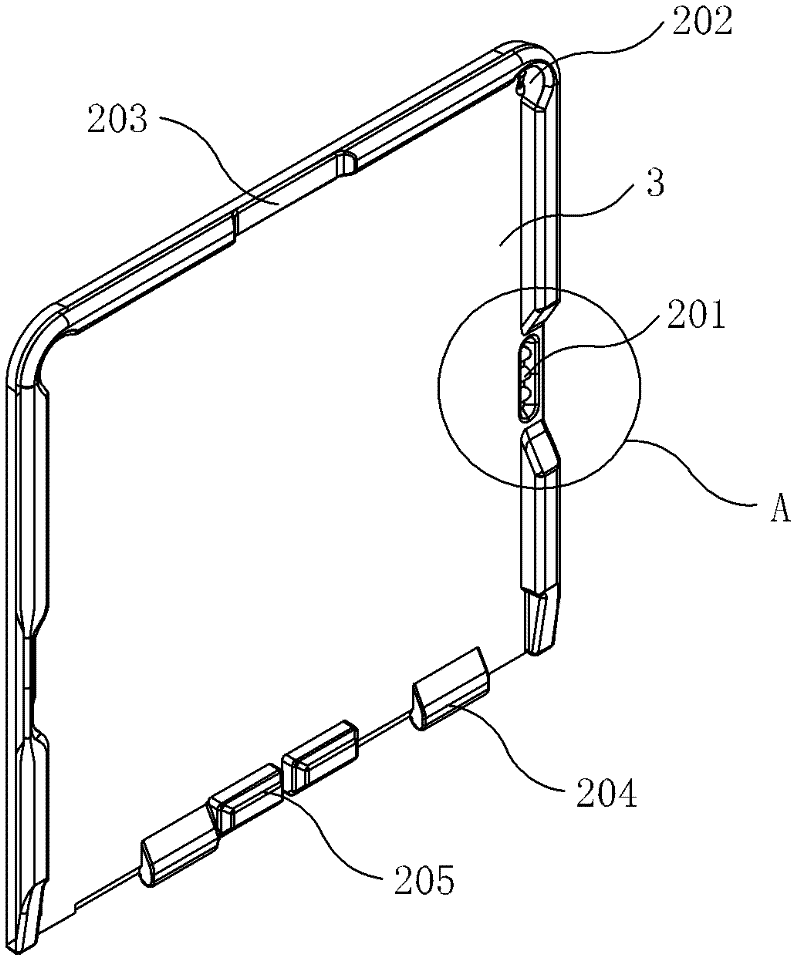

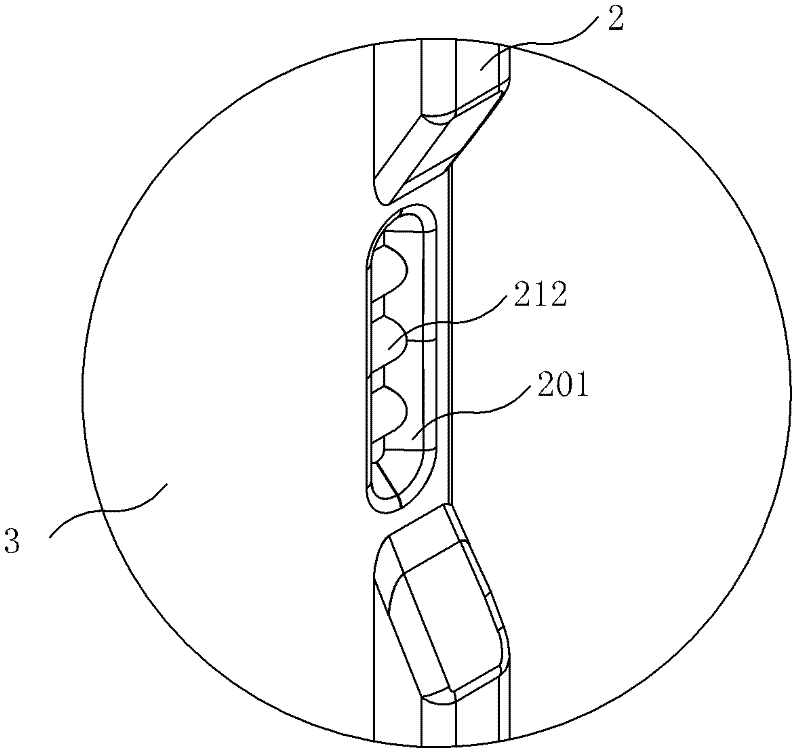

[0025] Now in conjunction with the accompanying drawings, the structure and use of the present invention will be further described. Such as Figure 6 As shown, the table top consists of one or two groups of table board monomers, the bottom of the table board monomers are respectively provided with table leg frames, and the two groups of table board monomers are connected as a whole by hinges. Such as Figure 1 to Figure 5 In the first embodiment shown, the hinge is arranged on the edge 2 of the reverse side 3, that is, the hinge rib 204 on the reverse side edge plane where the two groups of desktop boards are connected; When the two groups of desktop panels are folded and folded, the table leg frame is fixed to the edge of the reverse side by the positioning rib; The opposite plane of the symmetrical edge of the hinge rib and the positioning rib is provided with a buckle groove 203, and the folded and folded desktop board unit is unfolded through the buckle groove. The othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com