Flux for electroslag overlay welding

An electroslag surfacing and flux technology, applied in arc welding equipment, welding medium, welding equipment, etc., can solve the problems of reduced welding slag peelability, high viscosity of molten welding slag, and thermal adhesion of welding slag, and achieve excellent welding. stability, good bead appearance, good bead shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

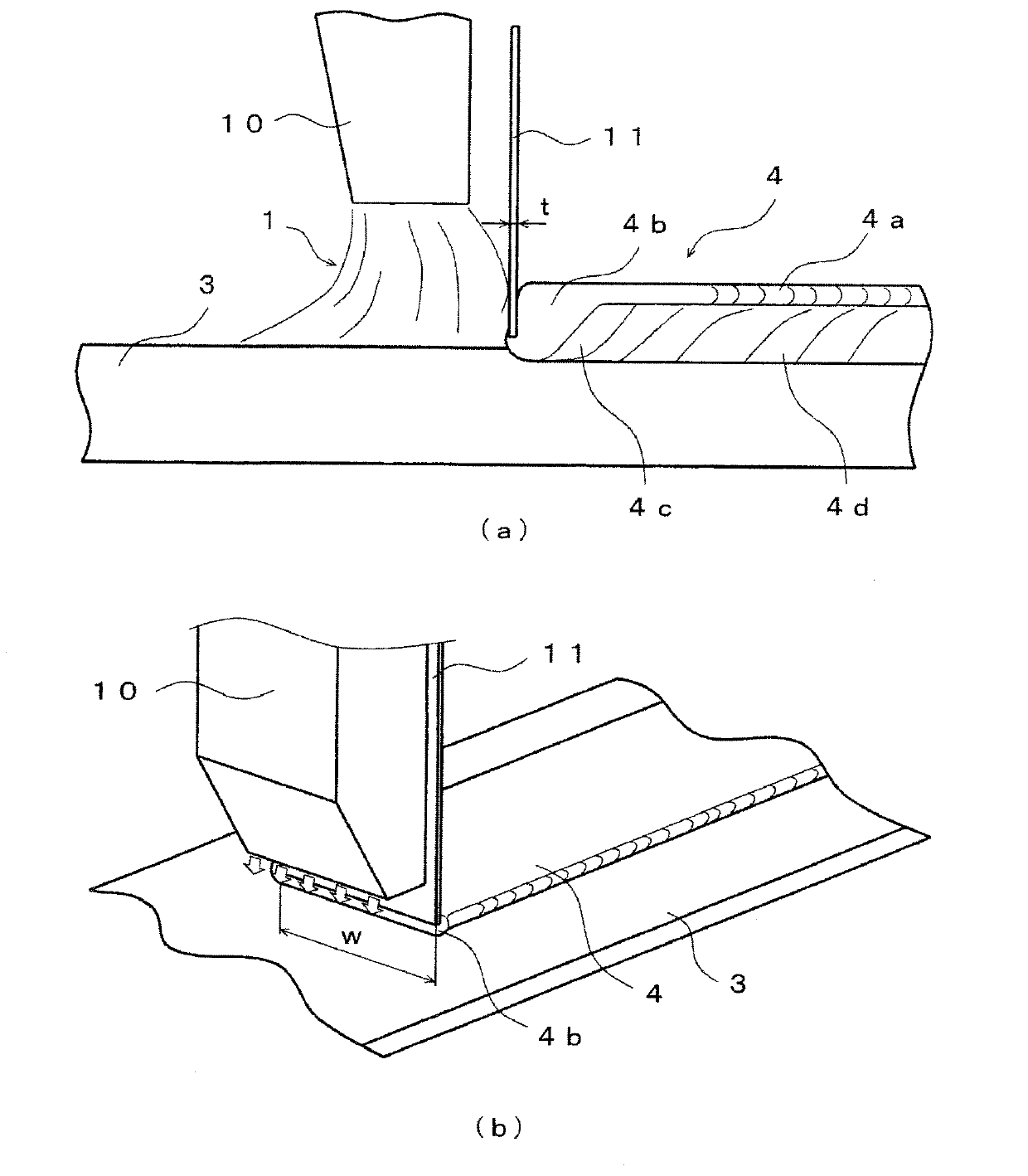

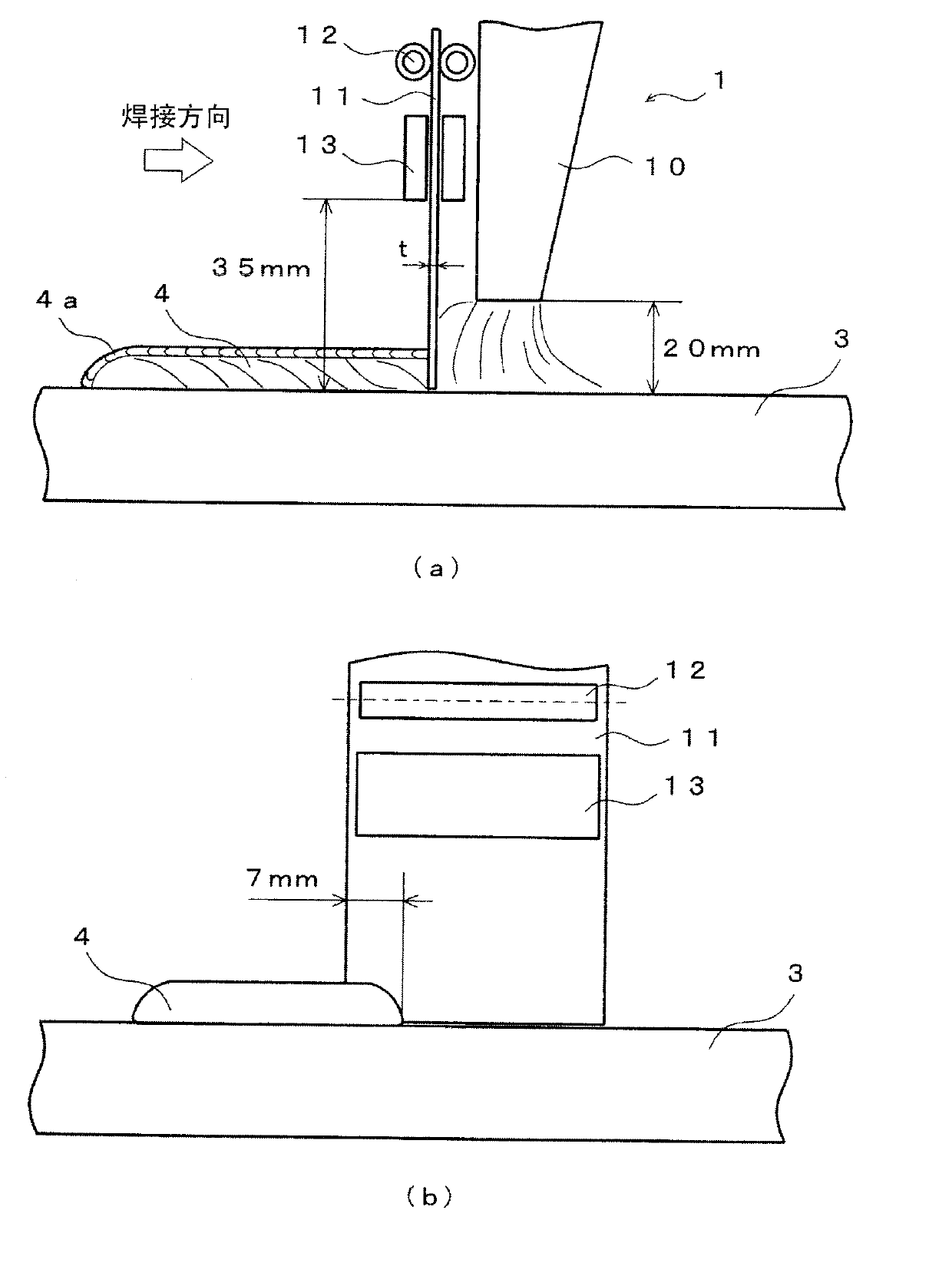

Method used

Image

Examples

Embodiment

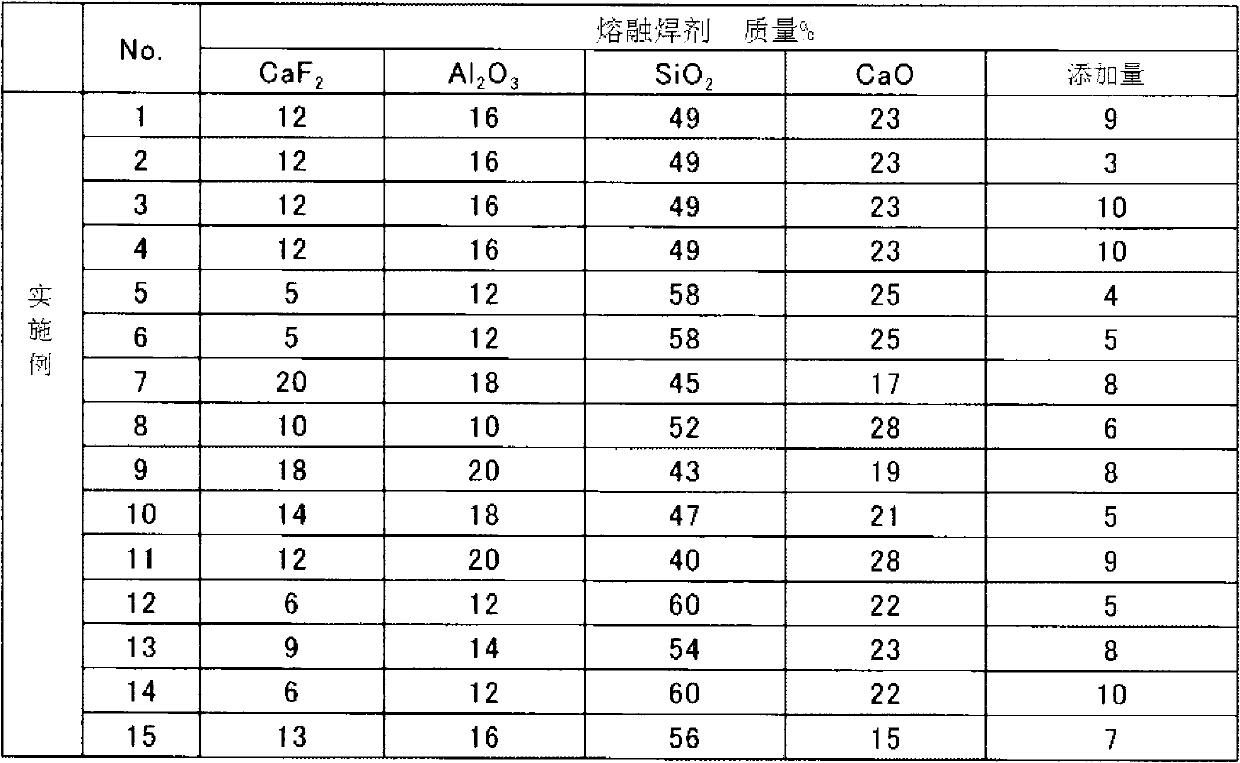

[0057] Next, examples showing the effects of the flux for electroslag overlay welding of the present invention will be specifically described in comparison with comparative examples.

[0058] First, a molten flux material is put into an electric furnace at a predetermined ratio, heated and melted by the electric furnace, and then cooled to obtain a solid molten flux material. The composition of each molten flux material is shown in Table 1-1 and Table 1-2. This molten flux material was pulverized, sized, and mixed as a part of raw materials for sintered flux to obtain a flux for electroslag overlay welding having the composition shown in Table 2-1 and Table 2-2. The addition amount of molten flux in the flux for electroslag overlay welding is collectively shown in Table 1-1 and Table 1-2. In addition, in Table 1-1 and Table 1-2, the column of the addition amount of molten flux is left blank for the case where the molten flux material cannot be obtained. In addition, in Table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com