Lead-free environmental silicon brass alloy bar or alloy ingot and preparation method thereof

A technology of alloy ingots and alloy rods, which is applied in the field of lead-free easy-cutting and environmentally friendly silicon brass alloy materials, can solve the problems of high-end product application of castings that affect casting costs, decline in casting yield, and lack of pouring, etc., to achieve excellent casting performance, Improved fluidity and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

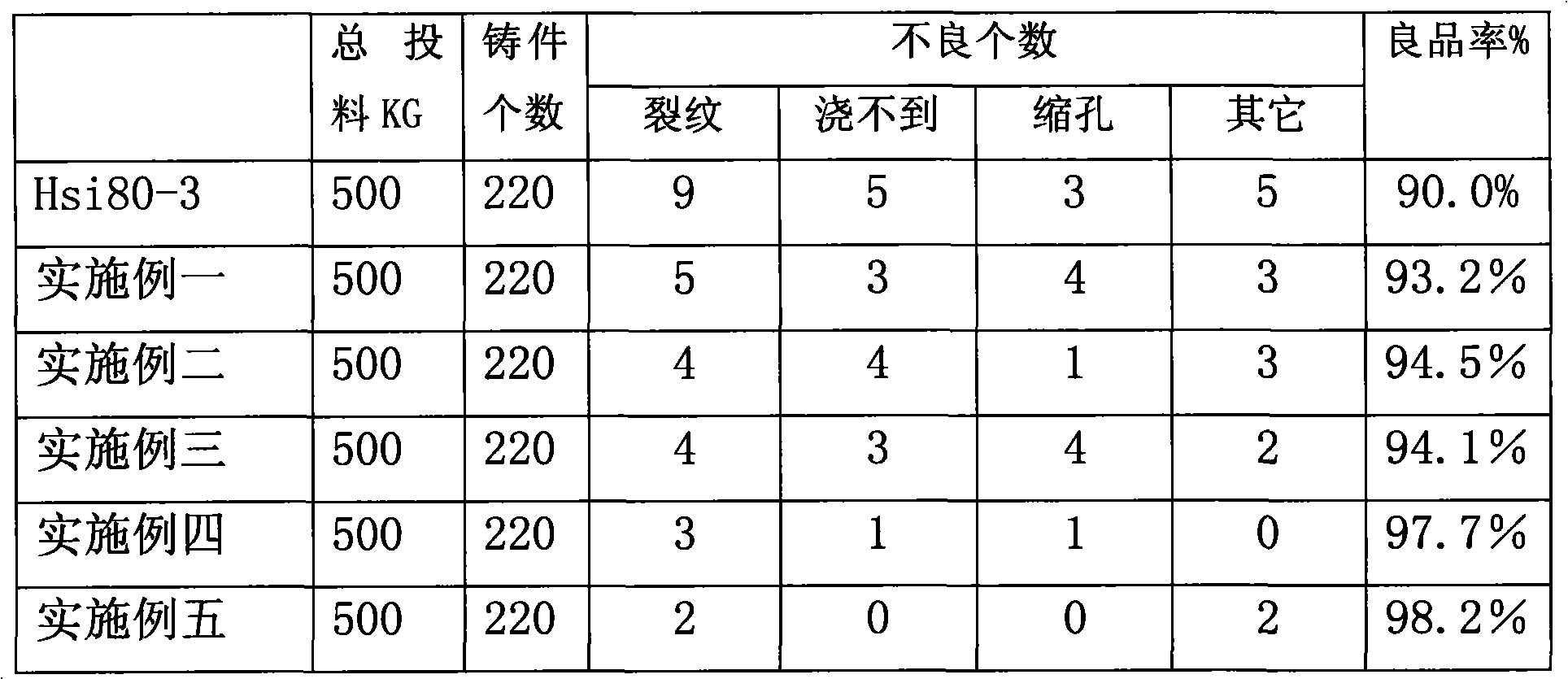

Examples

Embodiment Construction

[0049] The lead-free and environment-friendly silicon brass alloy rod or alloy ingot and the preparation method thereof of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples, but the protection scope of the present invention cannot be limited by this.

[0050] The general composition requirements of the lead-free and environmentally friendly silicon brass alloy rod or alloy ingot involved in the present invention are as follows:

[0051] Element Mass %

[0052] Copper: 60%~70%

[0053] Silicon: 0.7%~30%

[0054] Aluminum: ≤0.15%

[0055] Lead: ≤0.25%

[0056] Iron: ≤0.5%

[0057] Tin: ≤0.3%

[0058] Phosphorus: ≤0.1%

[0059]Nickel: ≤0.2%

[0060] Antimony: ≤0.25%

[0061] The balance is zinc and unavoidable impurities.

[0062] On the premise of the above composition requirements, as an optimized configuration to achieve better technical effects, the following scheme is proposed:

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com