6410C aluminum alloy

A technology of aluminum alloy and alloy film, applied in the field of aluminum alloy, can solve problems such as color difference, unstable gloss of high-gloss aluminum oxide trim, poor corrosion resistance, etc., to improve surface quality, reduce effective contact height, and reduce shrinkage rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

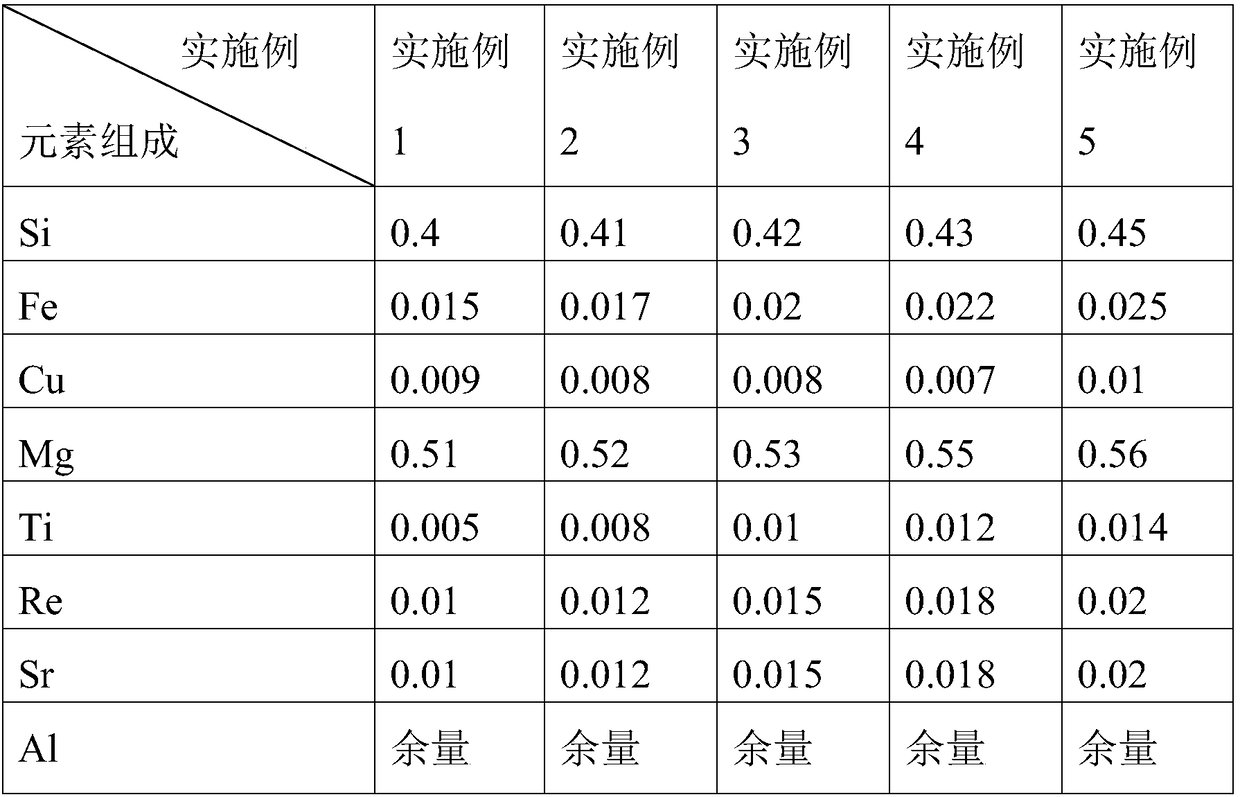

[0038] S1. According to the composition of the 6401C aluminum alloy in Example 1 in Table 1, place 99.99% high-purity refined aluminum ingots with a weight ratio of 4:1 and 99.70% remelting aluminum ingots in an aluminum smelting furnace and heat to 730°C Melted into liquid aluminum;

[0039] S2. Perform the first slag removal treatment on the molten aluminum in the smelting furnace, then add Si and Mg elements first, then add Ti, Re and Sr and pass in argon and refining agent for refining, and then perform the second slag removal treatment , and let it stand for 30 minutes; the Re element is added in the form of an aluminum rare earth master alloy, the Sr element is added in the form of an aluminum strontium master alloy, and the Ti element is added in the form of an aluminum titanium boron master alloy refiner;

[0040] S3. Lead the aluminum liquid in the aluminum smelting furnace to the casting furnace through the aluminum liquid flow channel at the set flow rate per unit t...

Embodiment 2

[0044] S1. According to the composition of the 6401C aluminum alloy in Example 2 of Table 1, place a 99.99% high-purity refined aluminum ingot with a weight ratio of 4.2:1 and a 99.70% remelting aluminum ingot in an aluminum smelting furnace and heat to 732°C Melted into liquid aluminum;

[0045] S2. Perform the first slag removal treatment on the molten aluminum in the smelting furnace, then add Si and Mg elements first, then add Ti, Re and Sr and pass in argon and refining agent for refining, and then perform the second slag removal treatment , and let it stand for 32 minutes; the Re element is added in the form of an aluminum rare earth master alloy, the Sr element is added in the form of an aluminum strontium master alloy, and the Ti element is added in the form of an aluminum titanium boron master alloy refiner;

[0046] S3. Lead the aluminum liquid in the aluminum smelting furnace to the casting furnace through the aluminum liquid flow channel at the set flow rate per un...

Embodiment 3

[0050] S1. According to the composition of the 6401C aluminum alloy in Example 3 of Table 1, put 99.99% high-purity refined aluminum ingot and 99.70% remelting aluminum ingot with a weight ratio of 4.5:1 in an aluminum melting furnace and heat to 735°C Melted into liquid aluminum;

[0051] S2. Perform the first slag removal treatment on the molten aluminum in the smelting furnace, then add Si and Mg elements first, then add Ti, Re and Sr and pass in argon and refining agent for refining, and then perform the second slag removal treatment , and let it stand for 35 minutes; the Re element is added in the form of an aluminum rare earth master alloy, the Sr element is added in the form of an aluminum strontium master alloy, and the Ti element is added in the form of an aluminum titanium boron master alloy refiner;

[0052] S3. Lead the aluminum liquid in the aluminum smelting furnace to the casting furnace through the aluminum liquid flow channel at the set flow rate per unit time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com