Method for preparing high-strength magnesium-lithium alloy by quick setting by using copper mold and copper mold

A magnesium-lithium alloy, high-strength technology, applied in the field of magnesium-lithium alloy preparation, can solve the problems of alloy plasticity reduction, and achieve the effects of high casting performance, fast heat conduction, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of the high-strength magnesium-lithium-aluminum alloy material:

[0019] The high-strength magnesium-lithium alloy prepared by the copper mold rapid solidification technology in the present invention is to use commercially pure Mg, commercially pure Li, and commercially pure Al as raw materials, according to its mass percentage Li: 2~11% (wt%), Al: 3~ The ratio of 6% (wt%) and the balance being Mg is smelted in a vacuum induction melting furnace. Before smelting, the furnace is evacuated to a vacuum state (when the reading of the vacuum gauge is 0.01MPa), and then filled with argon for protection. The melting process has been carried out under the protection of argon atmosphere. The melting temperature is 650-750°C. The heat preservation and standing time is 20-40min. After standing still, the melt (casting temperature is about 700°C) is cast into a square mold made of copper with a thickness of 20-25mm. The inner cavity size of the copper mold ...

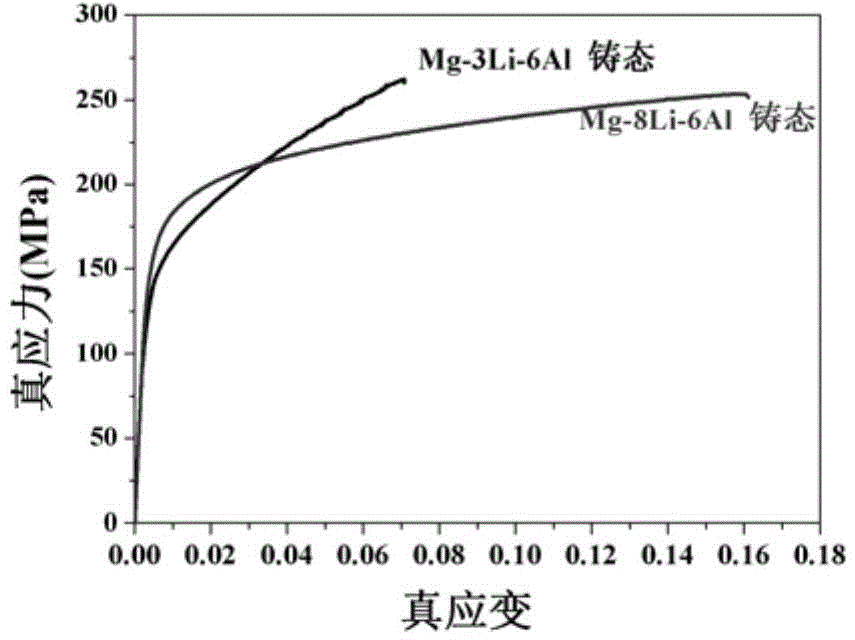

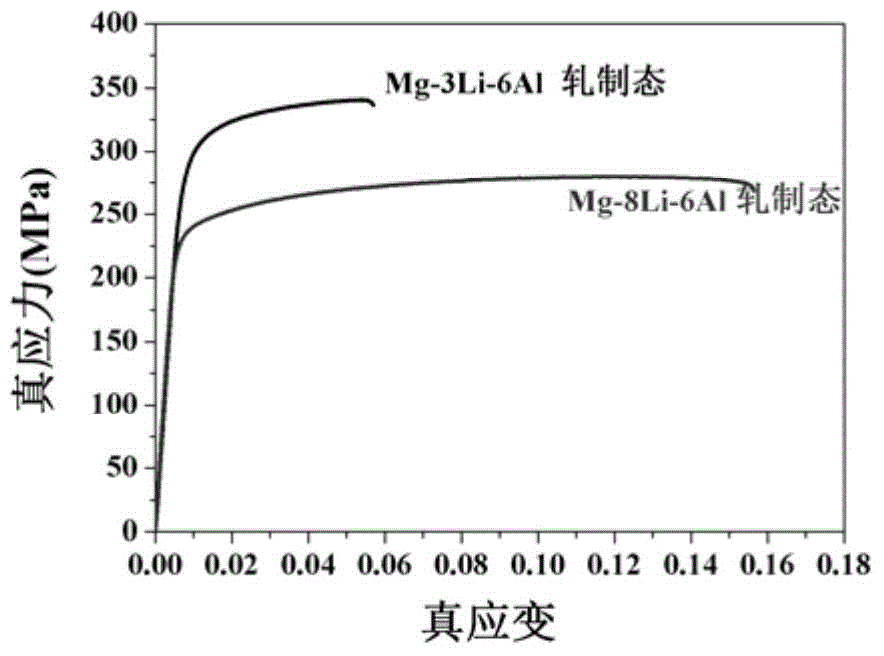

Embodiment 1

[0023] The chemical composition (mass percentage) of the alloy is: Li: 3%, Al: 6%, the total amount of inevitable impurities such as Fe, Cu, Ni, Si, etc. is less than 0.03%, and the balance is Mg.

[0024] The casting and processing techniques for preparing alloys are:

[0025] First, weigh the material according to the proportion, add the prepared Mg, Li and Al alloys into the steel crucible of the vacuum induction melting furnace, evacuate to 0.01MPa, and then fill it with argon. The melting process has been carried out under the protection of argon atmosphere. The melting temperature is about 720°C. After the metal is completely melted, keep it warm for 30 minutes, and then cast the melt (casting temperature is about 700°C) into the prepared copper cup with a thickness of 20mm and a length, width and height of 150mm*55mm*200mm (the inner cavity size is 120mm). *15mm*200mm) square mold, the punching ratio of the molten metal is 3 / 4, the rising speed of the molten metal in ...

Embodiment 2

[0027] The chemical composition (mass percentage) of the alloy is: Li: 8%, Al: 6%, the total amount of inevitable impurities such as Fe, Cu, Ni, Si, etc. is less than 0.03%, and the balance is Mg.

[0028] The casting and processing techniques for preparing alloys are:

[0029]First, weigh the material according to the proportion, add the prepared Mg, Li and Al alloys into the steel crucible of the vacuum induction melting furnace, evacuate to 0.01MPa, and then fill it with argon. The melting process has been carried out under the protection of argon atmosphere. The melting temperature is about 720°C. After the metal is completely melted, keep it warm for 30 minutes, and then cast the melt (casting temperature is about 700°C) into the prepared red copper with a thickness of 20mm and a length, width and height of 150mm*55mm*200mm (the inner cavity size is In a square mold of 120mm*15mm*200mm), the punching ratio of the molten metal is 3 / 4, the rising speed of the molten metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com