Raw material composition for valve castings special for medium and high pressure oil fields and production method for raw material composition

A technology of raw material composition and production method, applied in valve devices, engine components, mechanical equipment, etc., can solve problems such as poor static pressure resistance and corrosion resistance of valves, general performance of castings, affecting normal use, etc., to reduce production. Cost, good spheroidization effect, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

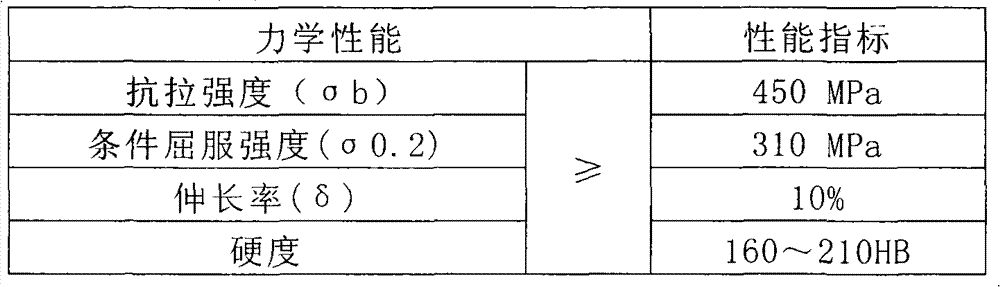

[0028] For the medium and high pressure oilfield special valve casting and its production method of this embodiment, the materials are weighed according to the weight part formula of the raw material composition, and the formula is as follows: Q10 pig iron 50-40 parts, low-phosphorus scrap steel 50-60 parts, ferromanganese 0.5-0.8 Parts, 8-10 parts of silicon carbide, 1.8-2.2 parts of waste copper, 0.2-0.3 parts of waste tin, 1.5-1.7 parts of spheroidizing agent, and 1-1.5 parts of inoculant.

[0029] According to the 0.5 ton intermediate frequency furnace specifications, 250 kg of Q10 pig iron, 250 kg of low-phosphorus scrap steel, 4 kg of silicon carbide, and 2.5 kg of ferromanganese are added to the electric furnace and heated to 1570~1600℃; 7.5 kg of nodulizer is added The bottom of the ladle is covered with inoculant and the upper part is covered with pressurized iron; 9 kg of copper scrap and 1 kg of tin are added to the other side of the ladle dam to prepare the molten iron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com