Ultra-fine grained eutectic high-entropy alloy and preparation method thereof

A high-entropy alloy and ultra-fine grain technology, applied in the field of alloys, can solve the problems of easy macrosegregation, low strength and plasticity of high-entropy alloys, and achieve the effects of excellent fluidity, simple preparation method and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

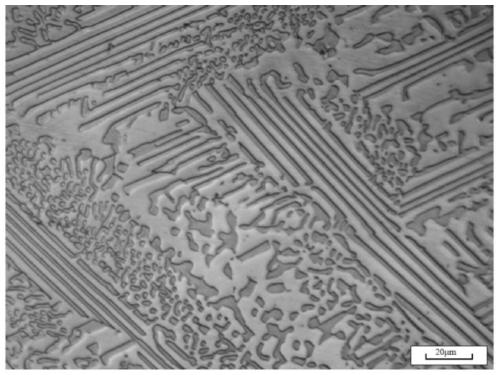

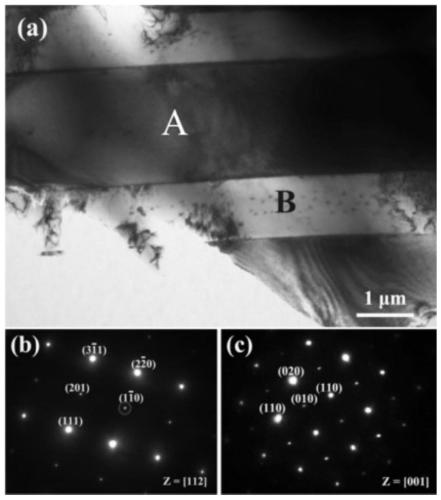

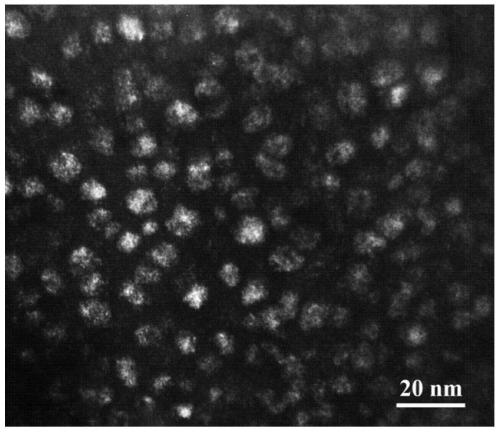

Image

Examples

Embodiment 1

[0035] This embodiment discloses an Al 1.0 Cr 1.0 co x Fe y Ni Z mn i m j Alloy, whose general formula is Al 1.0 Cr 1.0 co 0.4 Fe 0.8 Ni 2.6 mn 0.4 W 0.1 V 0.05 ,

[0036] Al above 1.0 Cr 1.0 co 0.4 Fe 0.8 Ni 2.6 mn 0.4 W 0.1 V 0.05 The preparation method of eutectic high-entropy alloy comprises the following steps:

[0037] Step 1: selecting pure raw materials of Al, Co, Cr, Fe, Ni, Mn, W, V elements with a purity of at least 99.5 wt%;

[0038] Step 2: Alkali washing the alloy raw material to remove oil, washing in NaOH alkaline solution for 5-60 minutes, removing surface oil, and finally rinsing with distilled water;

[0039] Step 3: pickling to remove the oxide film, ultrasonic cleaning in hydrofluoric acid, nitric acid, and distilled aqueous solution for 5-60 minutes, to remove the surface oxide skin. Then rinse with distilled water and dehydrate with alcohol solution;

[0040] Step 4: Prepare the designed alloy with an analytical electronic balanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com