Hollow steel for vanadium microalloyed rock drilling and preparation method thereof

An alloying and vanadium micro technology, applied in metal rolling, temperature control and other directions, can solve problems such as affecting the life of rock drilling, and achieve the effect of uniform and fine structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

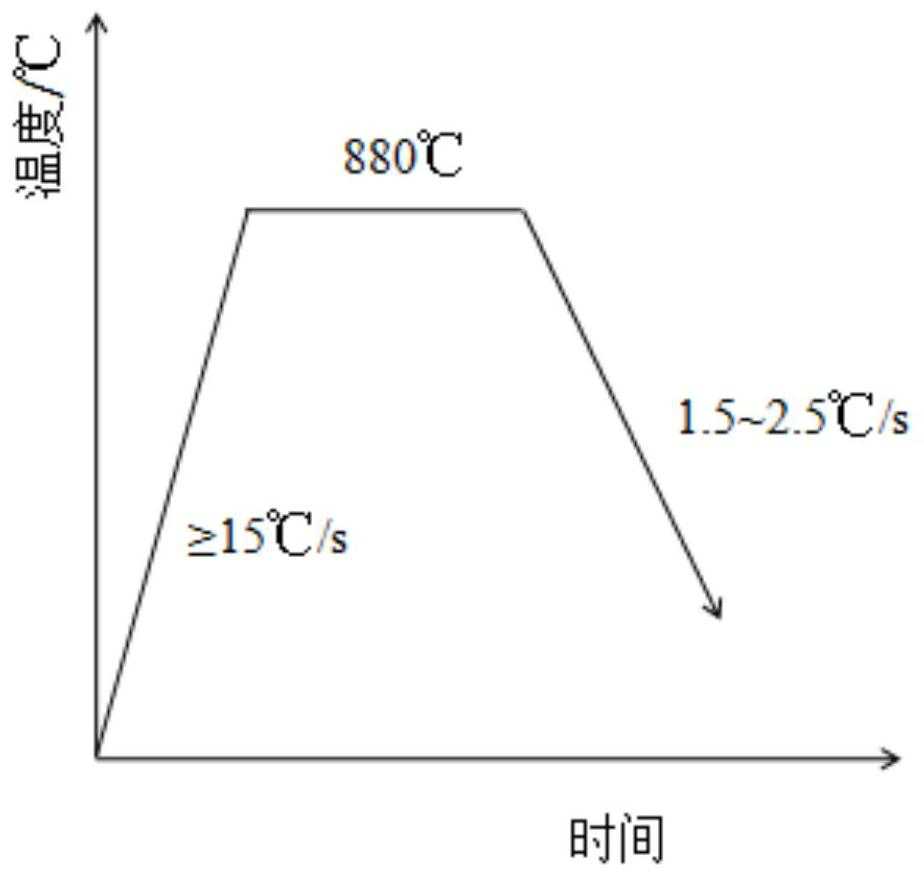

[0044]According to another optional embodiment of the present invention, a method for preparing the vanadium microalloyed hollow steel for rock drilling is provided, such as Figure 5 Shown, described preparation method comprises:

[0045] S1. Smelting and continuous casting the molten steel with the chemical composition of the vanadium microalloyed hollow steel for rock drilling to obtain a billet;

[0046] S2. Perforating the center of the steel billet, and putting the core material into the hole to obtain a raw steel billet;

[0047] S3. Heating the raw steel slab, followed by rough rolling and finish rolling, and air cooling to room temperature to obtain hollow steel for vanadium microalloyed rock drilling; wherein, the heating soaking temperature is 1100-1180°C, and the total heating time ≤2h; the inlet temperature of the rough rolling is 1000-1050°C, the outlet temperature of the finish rolling is 800-900°C; the air cooling rate is greater than>0.3°C / s.

[0048] The pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com