Environment-friendly manganese brass alloy and manufacturing method thereof

一种黄铜合金、锰黄铜的技术,应用在环保型锰黄铜合金及其制造领域,能够解决合金冷加工性能不理想、产品缺乏市场竞争力、Pb元素溶出量超标等问题,达到改善抗应力腐蚀性能、提高抗应力腐蚀性能、改善强化作用的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

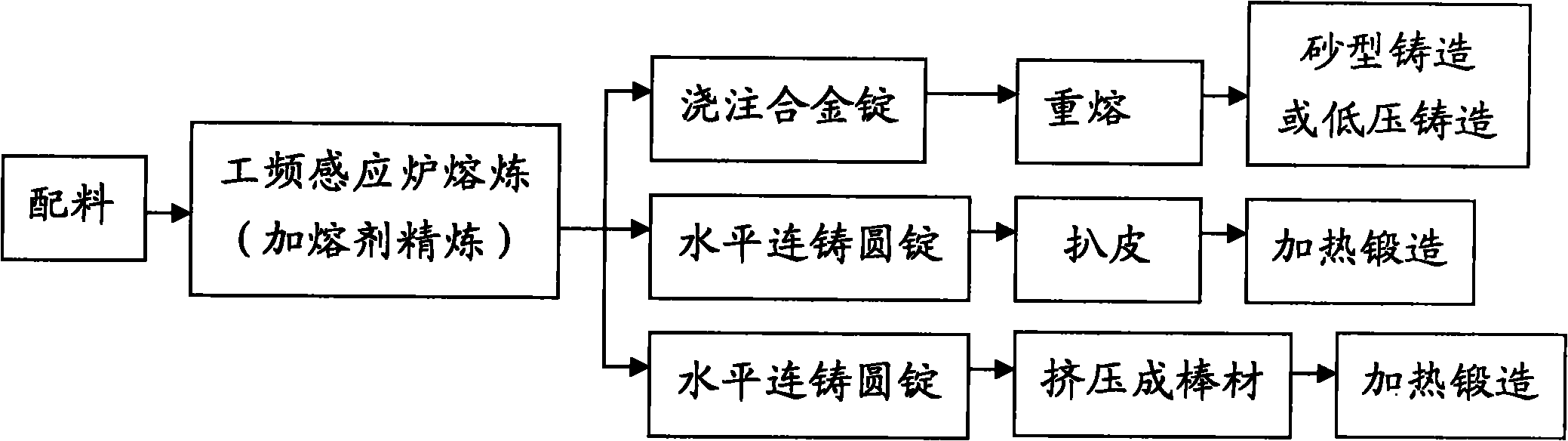

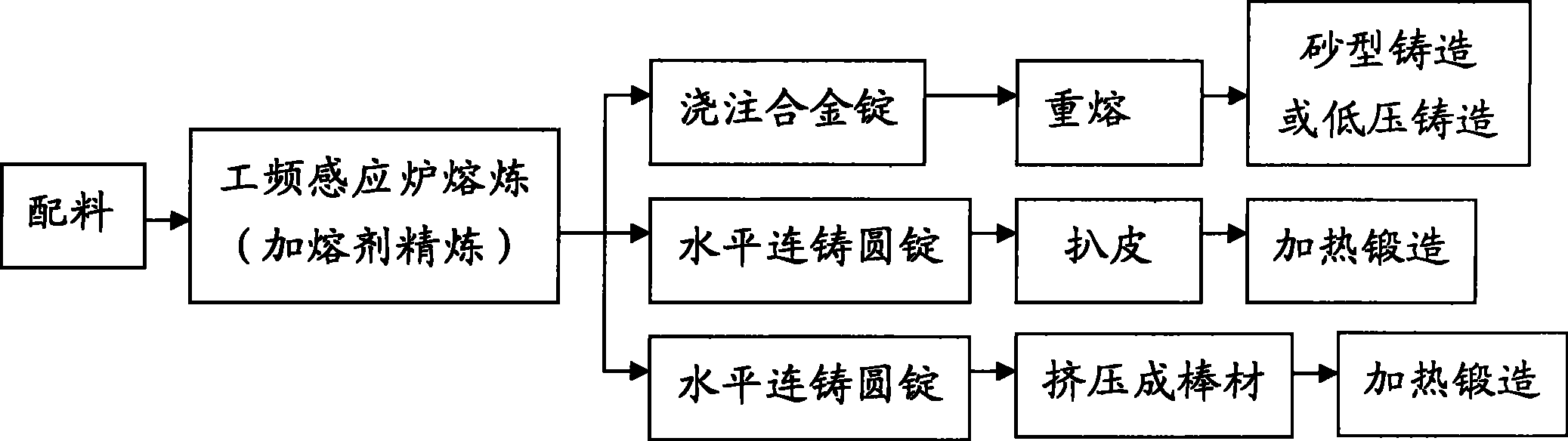

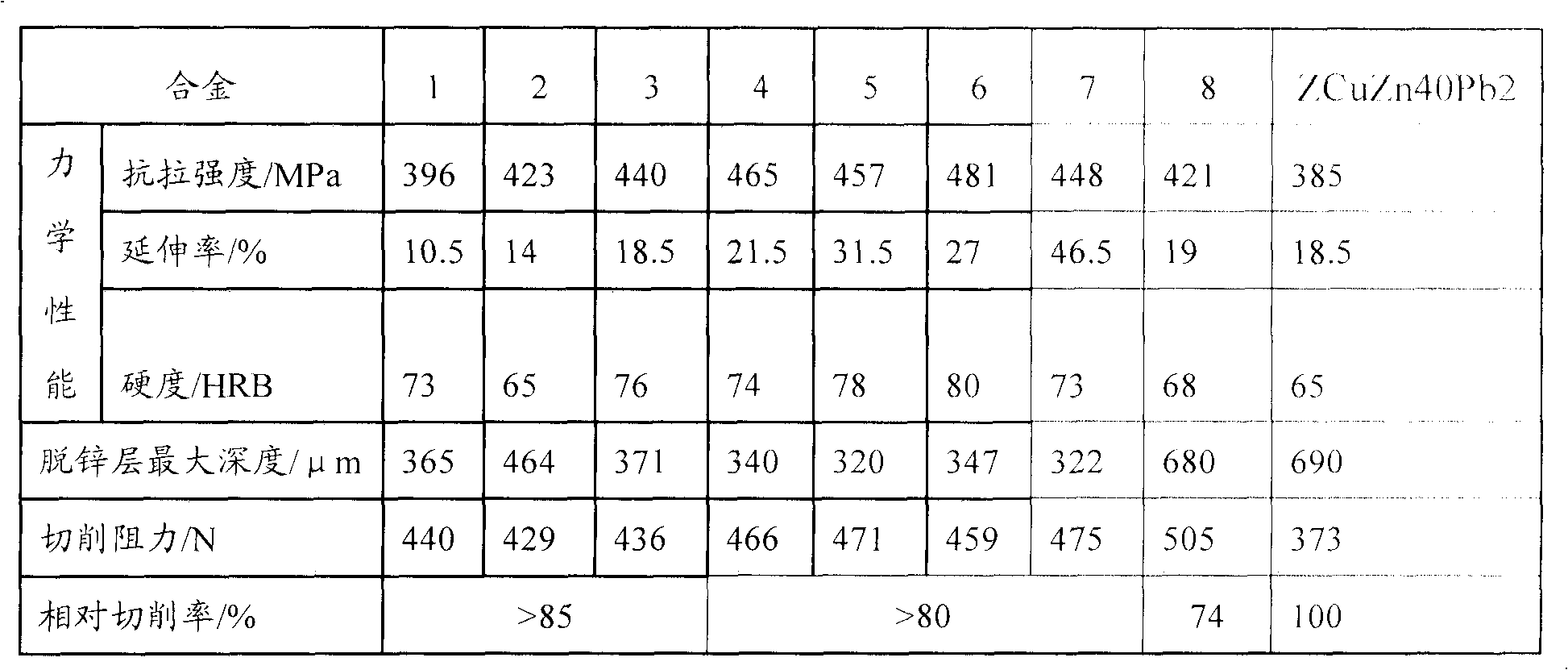

[0044] The brass alloy composition of the embodiment of the present invention and the alloy composition used as comparative study are listed in Table 1, wherein, alloy ingot 1-4 is used for sand casting, and the preparation process is as shown in Figure 1, and alloy 5-8 is used for horizontal The continuous casting round ingot is hot forged, and the preparation process is shown in Figure 1. The alloy ZCuZn40Pb2 is an outsourced comparative alloy.

[0045] Table 1 alloy composition of the embodiment of the present invention and contrast alloy composition (wt %)

[0046]

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com