Chemical polishing liquid used for metal and polishing technology

A technology of chemical polishing and polishing liquid, which is applied in the field of metal surface treatment, can solve the problems of high production cost, human environment hazards, and few applications, and achieve the effects of avoiding the release of harmful gases, being stable and not easy to decompose, and high polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

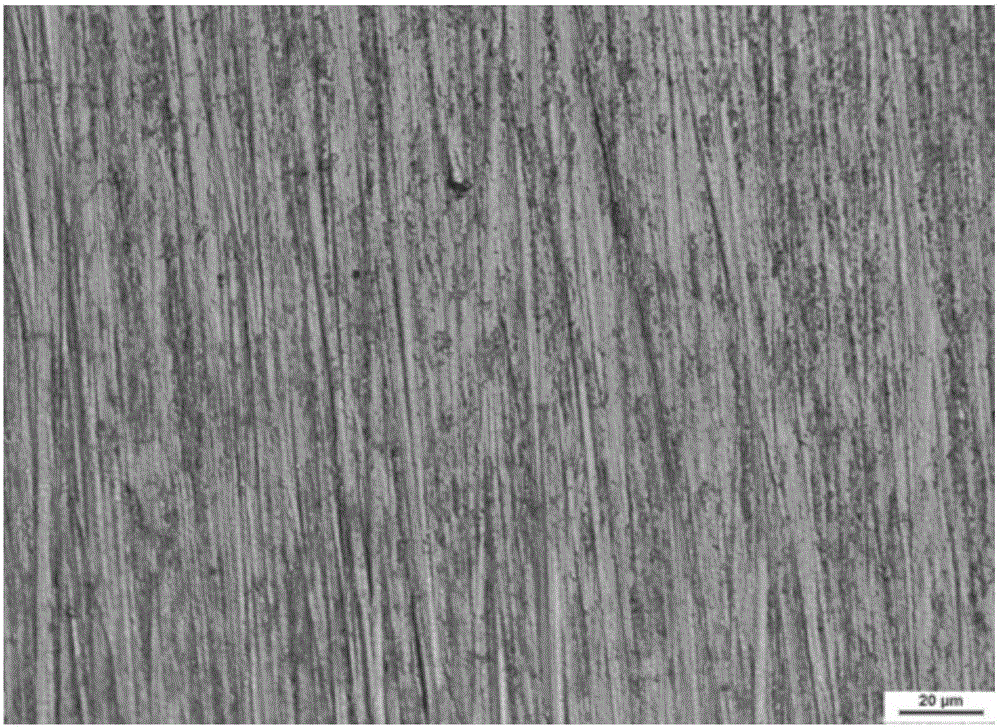

[0031] In this embodiment, 304 stainless steel is used as the base material, and the following chemical polishing liquid and polishing method are used to carry out the surface treatment method on the stainless steel surface. The specific steps are as follows:

[0032] (1) Pretreatment degreasing and activation of the metal surface: the surface of the stainless steel sample formed by wire cutting is polished with sandpaper, rinsed with distilled water and dried; the sample is placed in an alkaline degreasing solution and soaked for 1 Minute oil removal, the concentration of each component in the alkaline solution is sodium hydroxide 30g / L, trisodium phosphate 50g / L, sodium carbonate 20g / L, OP emulsifier 5mL / L, and then rinse with distilled water and use Rinse with ionized water and dry with a hair dryer. Then carry out pickling and activation treatment for 10 seconds, the activator is 10% sulfuric acid, then rinse with distilled water, rinse with deionized water, and then blow ...

Embodiment 2

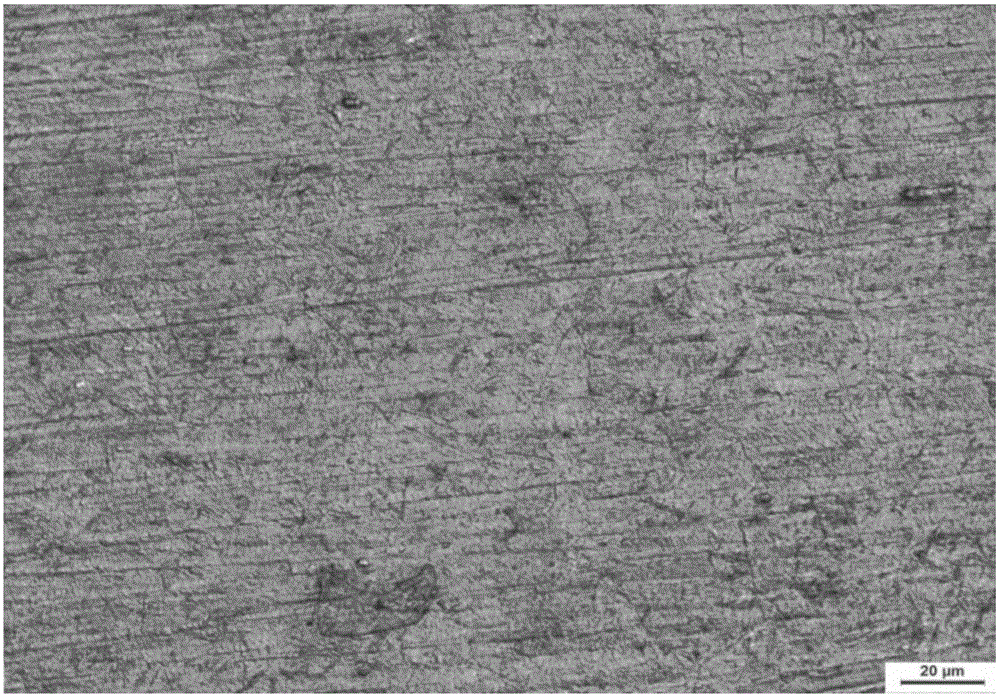

[0037] In this embodiment, 304 stainless steel is used as the base material, and the following chemical polishing liquid and polishing method are used to carry out the surface treatment method on the stainless steel surface. The specific steps are as follows:

[0038] (1) Pretreatment degreasing and activation of the metal surface: the surface of the stainless steel sample formed by wire cutting is polished with sandpaper, rinsed with distilled water and dried; the sample is placed in an alkaline degreasing solution and soaked for 1 Minute oil removal, the concentration of each component in the alkaline solution is sodium hydroxide 30g / L, trisodium phosphate 50g / L, sodium carbonate 20g / L, OP emulsifier 5mL / L, and then rinse with distilled water and use Rinse with ionized water and dry with a hair dryer. Then carry out pickling and activation treatment for 10 seconds, the activator is 10% sulfuric acid, then rinse with distilled water, rinse with deionized water, and then blow ...

Embodiment 3

[0043] In this embodiment, 304 stainless steel is used as the base material, and the following chemical polishing liquid and polishing method are used to carry out the surface treatment method on the stainless steel surface. The specific steps are as follows:

[0044] (1) Pretreatment degreasing and activation of the metal surface are exactly the same as in Examples 1 and 2. After degreasing and activating, rinse with distilled water, rinse with deionized water, and then dry with a hair dryer.

[0045](2) Place the sample in a chemical polishing solution and immerse it at 80°C for 3 minutes. During the chemical polishing process, the solution is stirred at a stirring rate of 300r / min, then rinsed with distilled water, then rinsed with deionized water, and then rinsed with Hairdryer to dry. The preparation of the polishing solution is as follows: prepare 100mL chemical polishing solution, in which the various components and concentrations in the polishing solution are as follow...

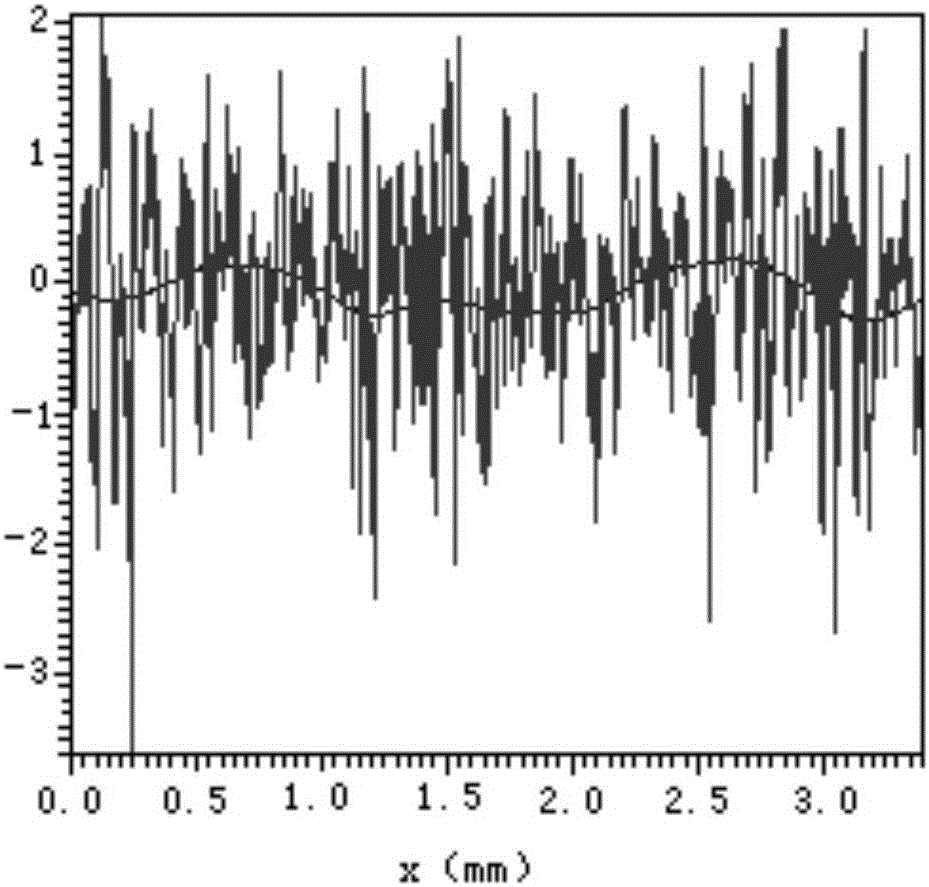

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com