Superfine and spheroidizing rare-earth polish and preparing process thereof

A rare earth polishing powder and preparation process technology, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of polishing powder with good reusability, poor polishing effect, poor reusability, etc., and achieve good polishing effect, The effect of fine powder particle size and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

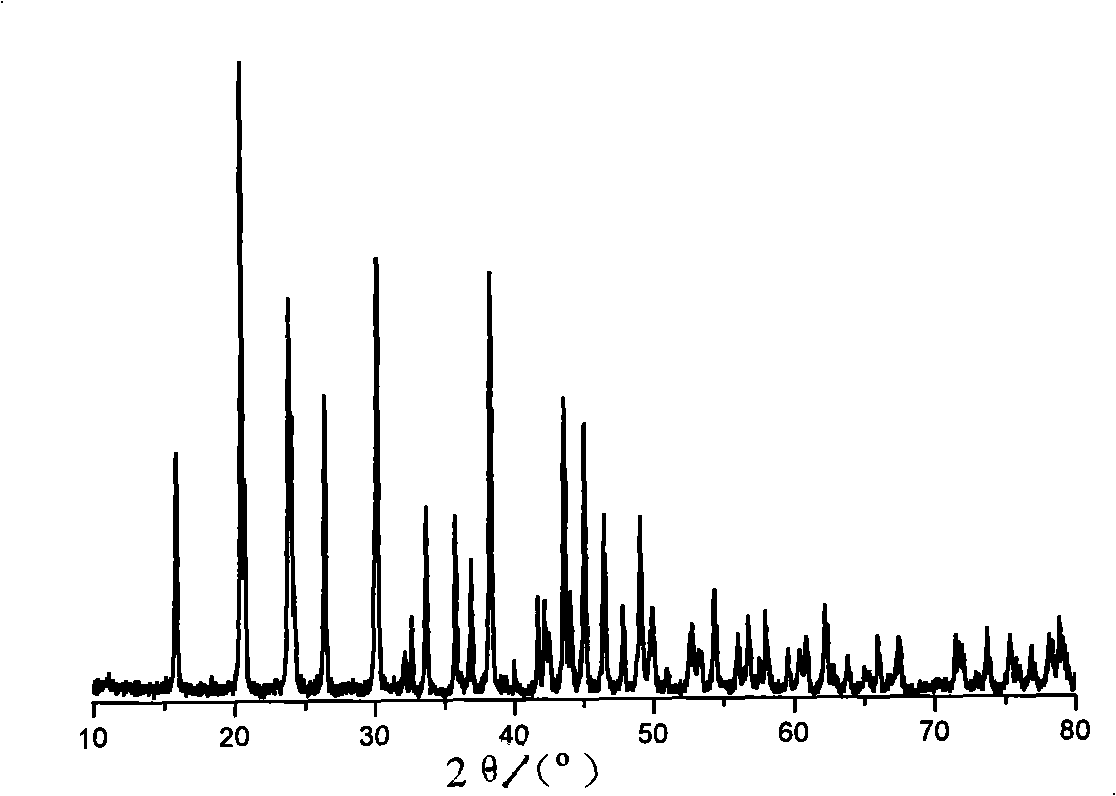

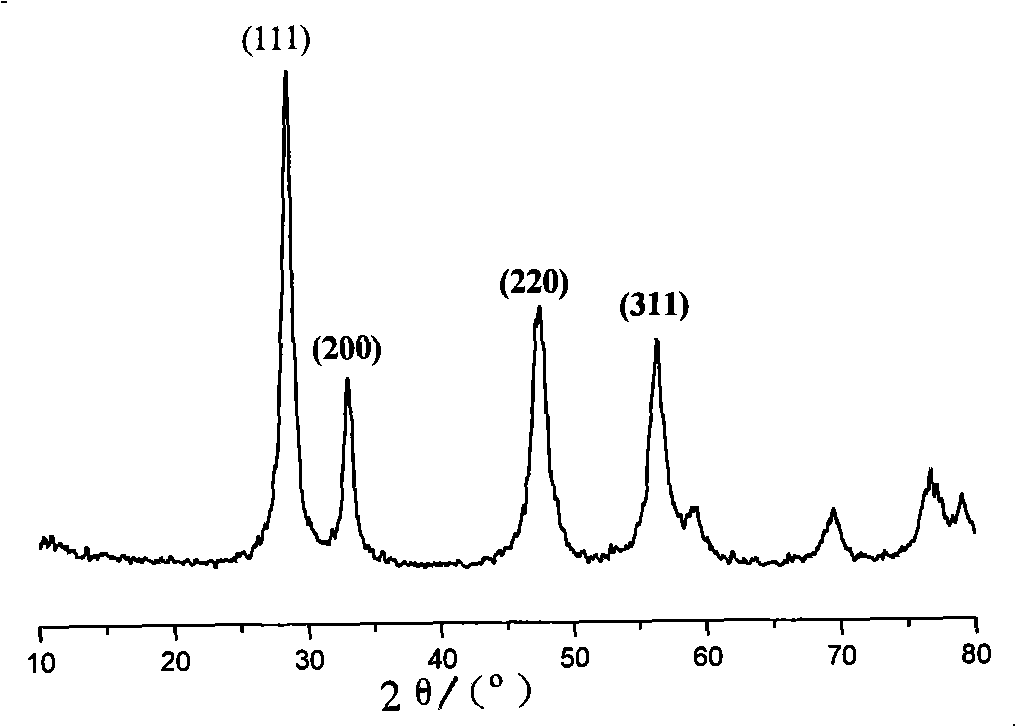

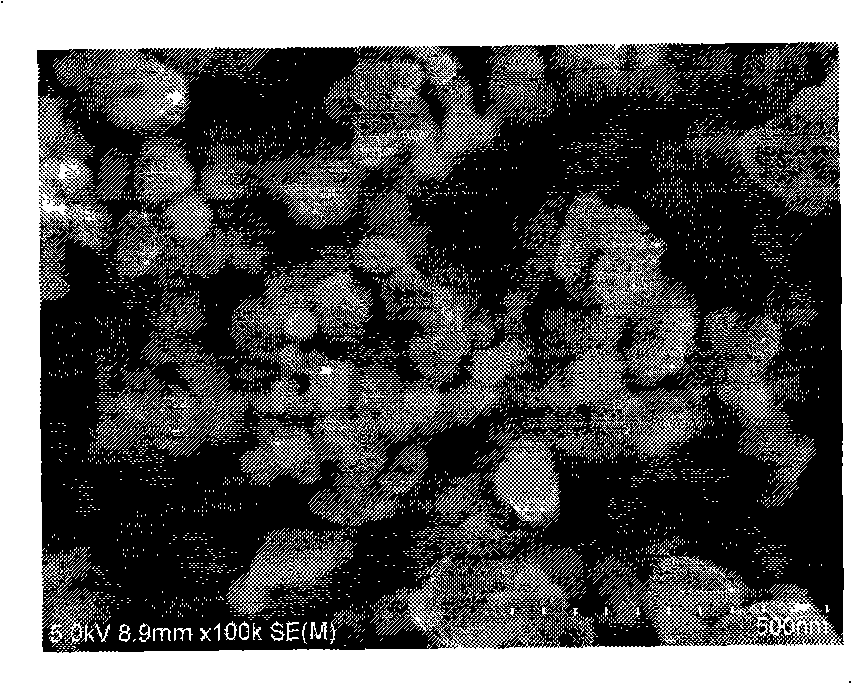

[0038] Example 1: Dissolve cerium chloride in water to make a 0.05 mol / L solution into a reactor, and heat it to 30°C. Add the prepared precipitant ammonium bicarbonate solution with a concentration of 0.1mol / L to the bottom solution at a rate of 2L / min; after the addition is completed, stir for 10 minutes, and add the ammonium ion at a concentration of 0.01 The weight percentage of mol / L ammonium chloride and F / TREO is 0.1% ammonium fluoride in the mixed solution; Mixed mother liquor is heated up to 90 ℃ and continues stirring reaction for 5 hours, makes reaction fully carry out, and obtains precipitation; Will obtain The precipitate was aged at 30°C for 0.5 hours; the precipitate was separated, collected, washed, and dried to obtain a white precursor powder, which was calcined at 600°C to obtain CeO 2 The powder is passed through a 200-mesh sieve after wet ball milling, and then centrifugally dried to obtain a high-performance ultrafine, spheroidized rare earth polishing pow...

example 2

[0039]Example 2: Dissolve lanthanum and cerium nitrate in water to form a 3 mol / L solution, put it into a reactor, and heat it to 80°C. Add the prepared precipitant ammonium carbonate solution with a concentration of 2.0mol / L into the base solution at a rate of 2L / min; after the addition is completed, stir for 10min, and add ammonium ions at a concentration of 1.0mol when calculated according to the volume of the mother liquor The weight percentage of / L ammonium nitrate and F / TREO is 10.0% ammonium fluoride in the mixed solution; the mixed mother liquor is heated up to 90 ° C, and the stirring reaction is continued for 5 hours, so that the reaction is fully carried out, and precipitation is obtained; the obtained precipitation Aged at 100°C for 48 hours; the precipitate was separated, collected, washed, and dried to obtain a white precursor powder, which was calcined at 1100°C to obtain La 2 o 3 -CeO 2 The powder is passed through a 500-mesh sieve after wet ball milling, an...

example 3

[0040] Example 3: Dissolve lanthanum, cerium, praseodymium, and neodymium sulfate in water to form a 1.5 mol / L solution in a reactor, and heat it to 40°C. Add the mixed solution of precipitant ammonium bicarbonate and ammonia water with a concentration of 1.0mol / L to the bottom solution at a rate of 2L / min; after the addition is completed, stir for 15min, and add ammonium ions when calculated according to the volume of the mother solution The concentration of 0.5mol / L ammonium sulfate and the weight percent of F / TREO are 1.0% ammonium fluorosilicate in the mixed solution; the mixed mother liquor is heated to 80 ° C, and the reaction is continued for 5 hours with stirring, so that the reaction is fully carried out, and obtained Precipitate; age the obtained precipitate at 60°C for 24 hours; separate, collect, wash, and dry the precipitate to obtain a white precursor powder, which is calcined at 900°C to obtain a mixed powder, which is wet ball milled After passing through a 400...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com