Flexible magnetic fluid brush polishing shaping machine for round tube

A shaping machine and round tube technology, applied to surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of high cost, environmental pollution, poor polishing effect, etc., and achieve strong adaptability, Strong controllability and easy automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

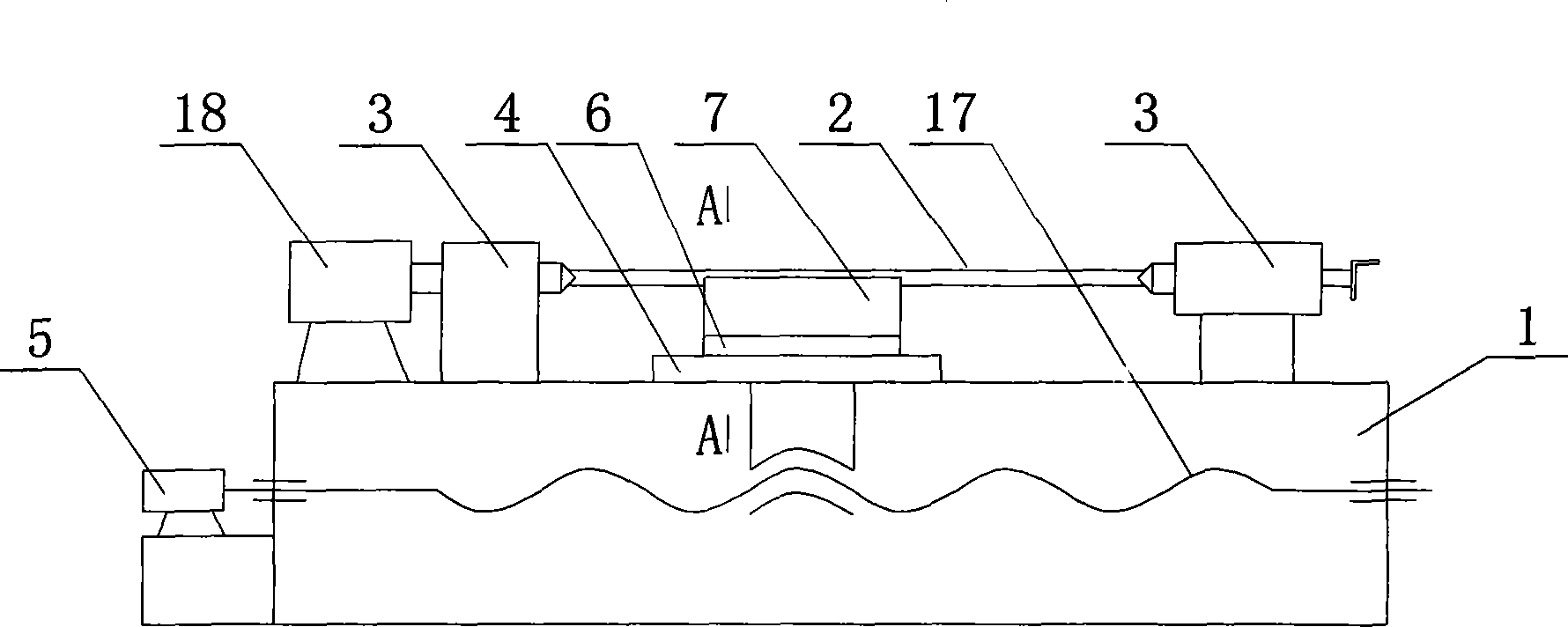

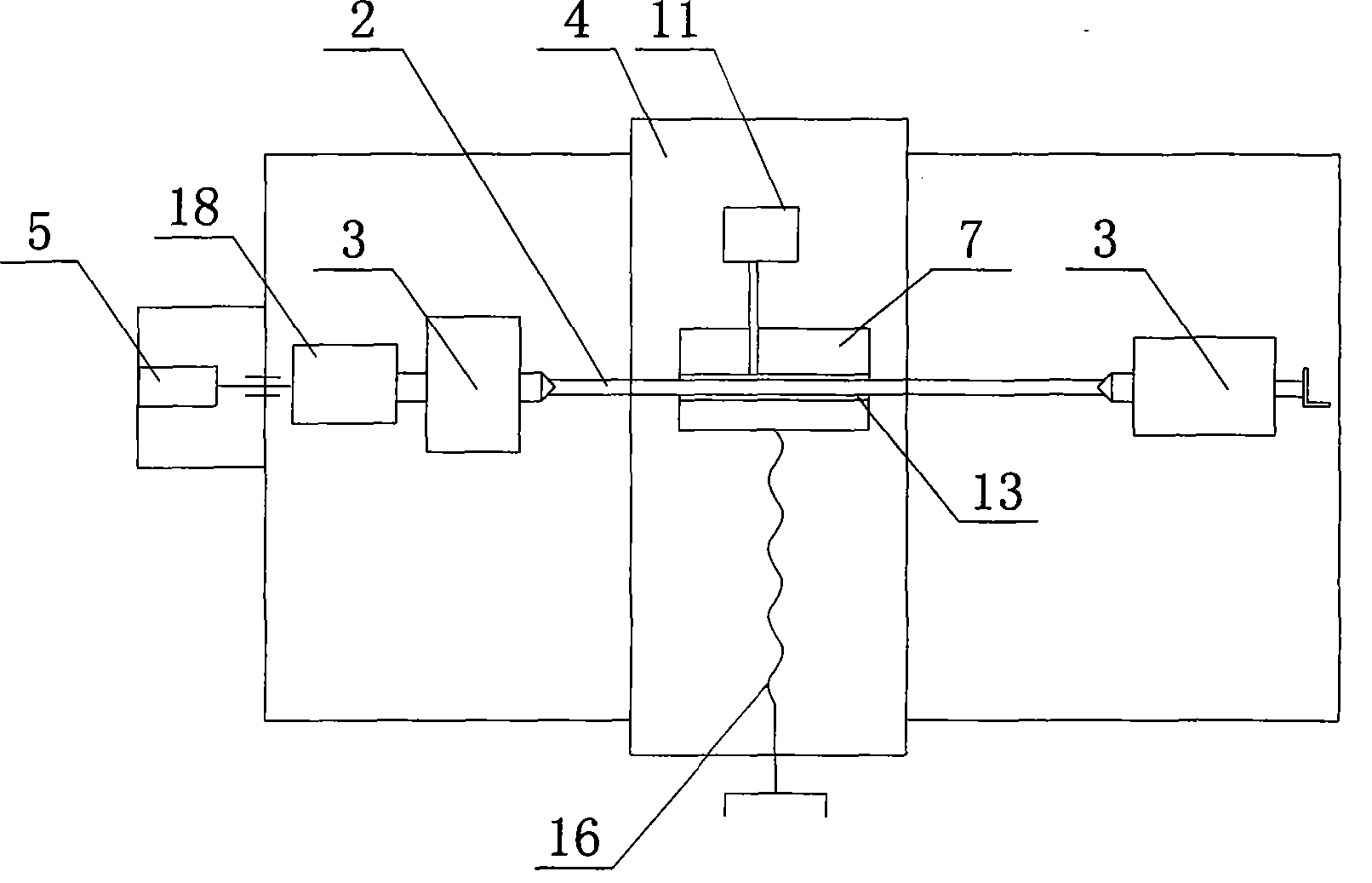

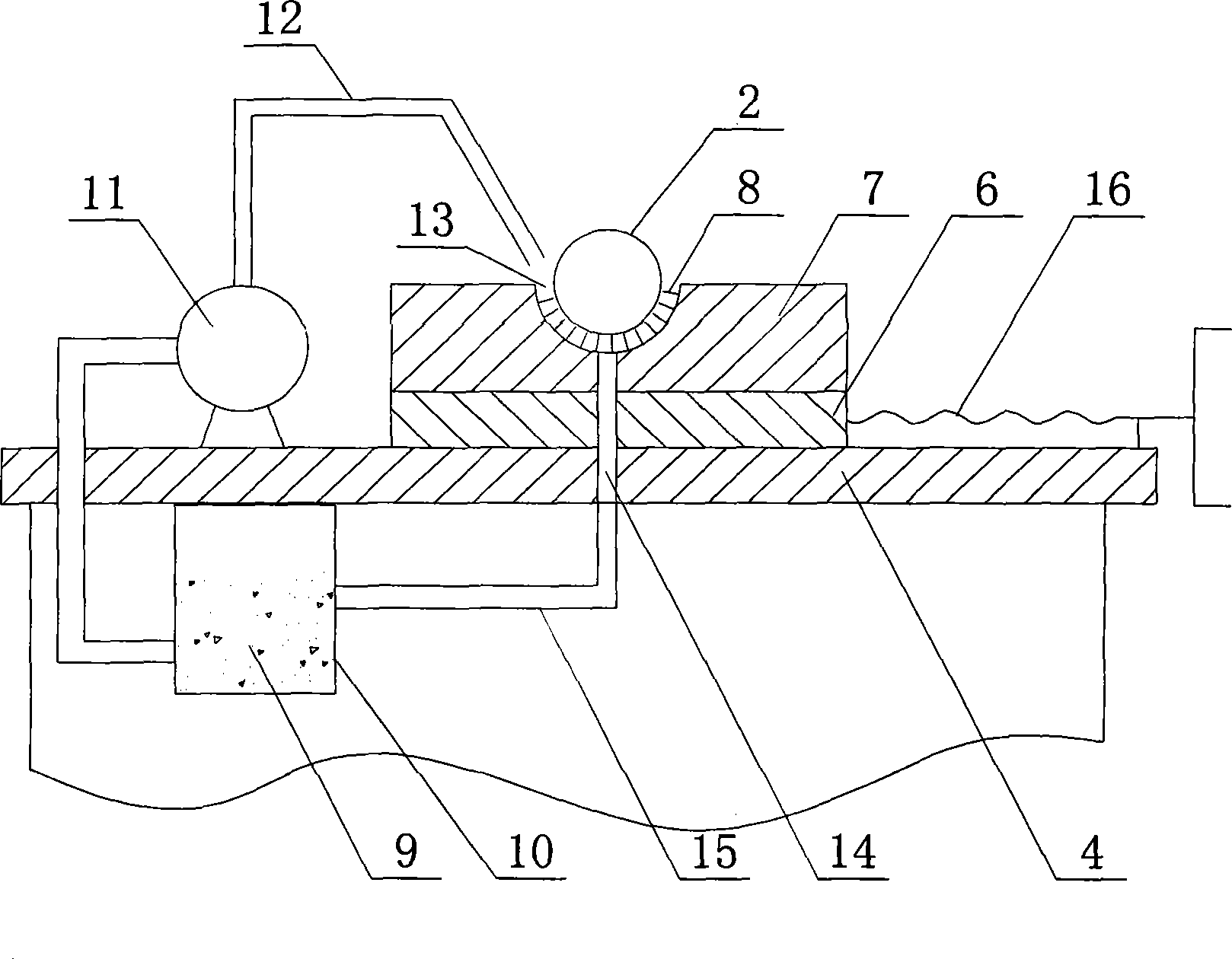

[0016] Refer to figure 1 , figure 2 This is an embodiment of the circular tube flexible magnetic current brushing and shaping machine of the present invention. The circular tube flexible magnetic current brushing and shaping machine includes a body 1, a top frame 3 arranged on the body 1 for fixing the circular tube 2, and a driving circle The rotating motor 18 that the tube 2 rotates, the pallet 4 slidably arranged on the fuselage 1, the main motor 5 that drives the pallet 4 to move laterally, the magnetic drive 6 arranged on the pallet 4, and the magnetic fixed on the magnetic drive 6 The brush body 7, the brush 8 fixed on the magnetic brush body 7 in contact with the round tube 2, also includes the magnetorheological fluid and the abrasive particle composition of the magnetorheological lightening liquid 9, spraying the magnetorheological lightening liquid 9 To the spray device on the brush 8, such as image 3 As shown, the spraying device includes a liquid storage tank 10 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com