Electropolishing preparation method of sample for EBSD (Electron Back-Scattered Diffraction) analysis of titanium-aluminum alloy

An electropolishing, base alloy technology, applied in the preparation of test samples, analysis of materials, sampling, etc., to achieve the effect of simple and flexible operation, portable equipment, and large sample area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In the specific implementation process, the electrolytic polishing preparation method of the sample for EBSD analysis of the titanium-aluminum base alloy of the present invention comprises the following steps:

[0034] (1) Sample pre-treatment:

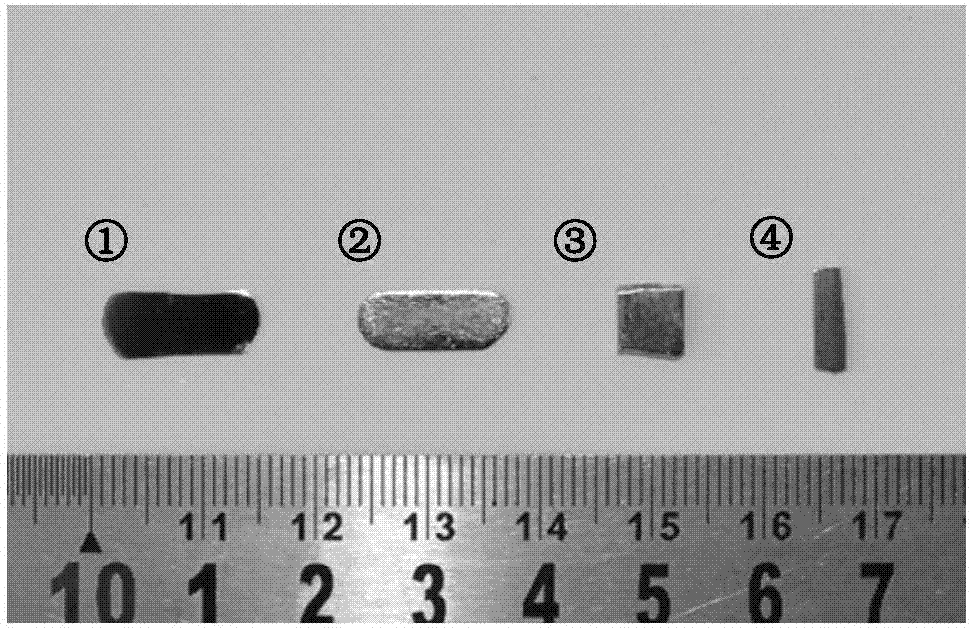

[0035] As an intermetallic compound, titanium-aluminum-based alloy is hard, with a hardness of up to HRC50~HRC60, and is relatively brittle at room temperature. The sample can be cut by wire cutting or water jet cutting (slow wire cutting during wire cutting, so as to facilitate subsequent grinding). Samples should not be processed by milling machines, lathes and grinding machines. The size of the cut BESD sample is usually below 10mm×10mm×5mm, of which 5mm is the limit value of the sample height, and the height direction of the sample is also the ND direction (normal direction) during the test. Preferably, the size of the cut BESD sample is (5-7) mm×(3-6) mm×(2-4) mm, where (2-4) mm is the height direction, and the difference...

Embodiment 1

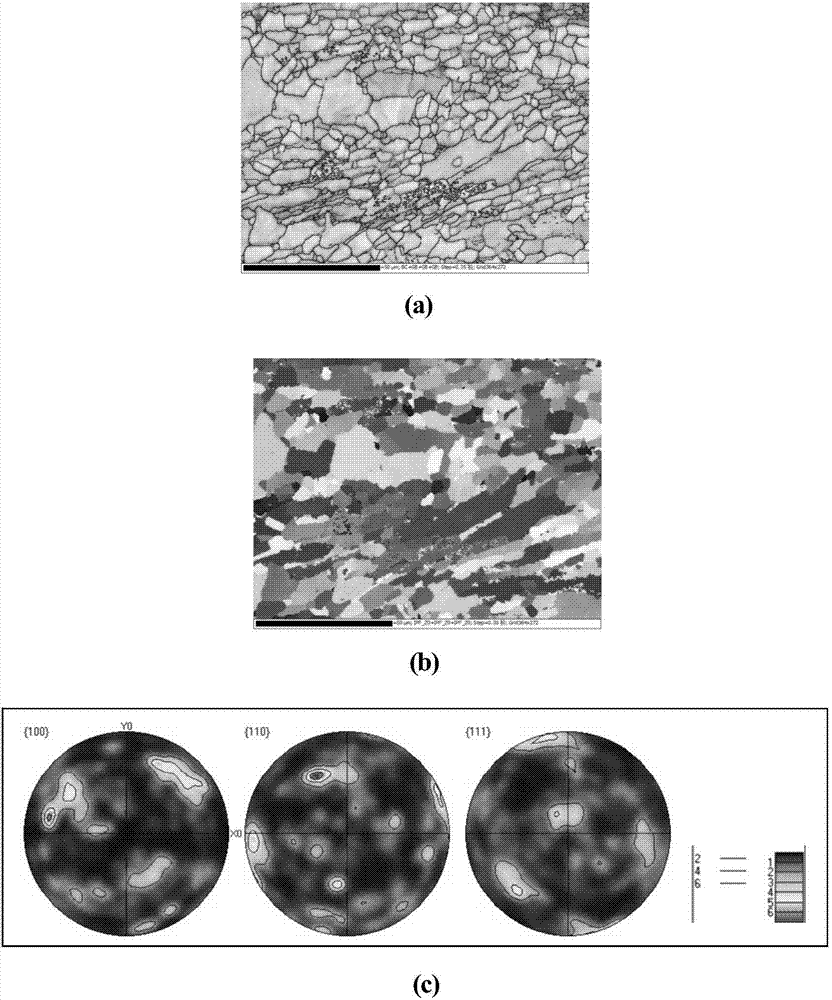

[0047] In this example, for the titanium-aluminum-based alloy subjected to high-temperature compression using the Gleeble thermal simulation testing machine, the sample for EBSD analysis was prepared by electrolytic polishing, including the following steps:

[0048] (1) Sample preparation:

[0049] Firstly, line-cut a sheet-like sample with a thickness of 0.5 mm at the center of the cake-shaped sample along the direction of compression. Since the sample is small and thin, it is necessary to move the wire slowly to reduce the depth of the wire-cut trace; wipe off the oil on the surface of the wire-cut sample, and Both sides of the cut flake sample are polished with 40#~800# sandpaper, and one side (test surface) is required to continue to be polished with standard metallographic method 1000#~5000# sandpaper; the thin sample is glued to the surface of the iron block with 502 for mechanical Polish until the surface is bright, then soak the thin slice sample in acetone, and clean ...

Embodiment 2

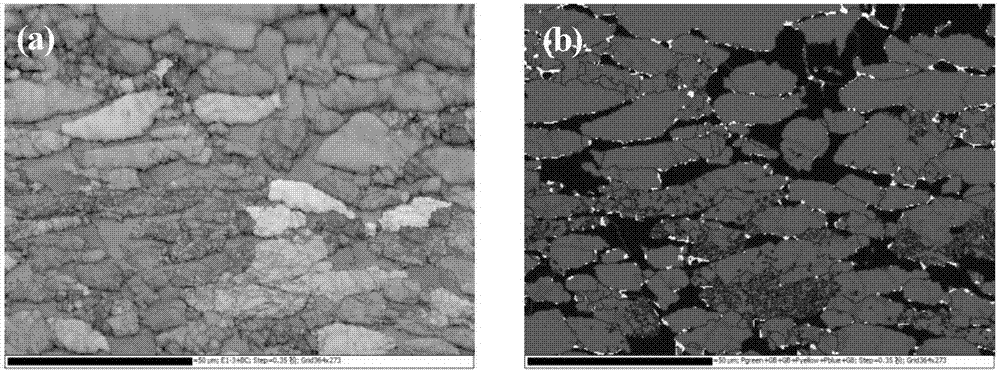

[0058] In this embodiment, for the sheet-shaped titanium-aluminum-based alloy I-shaped piece stretched at room temperature, the electrolytic polishing method is used to prepare the sample for EBSD analysis, including the following steps:

[0059] (1) Sample preparation:

[0060] Use pliers to break off a small piece at the gauge length, about 6mm×5mm×1.9mm (1.9mm is the sample height, as the ND direction in the EBSD test), the two 6mm×5mm surfaces of the sample are relatively smooth (the two sides of the I-shaped piece have been Use 800# sandpaper to polish), as above, carry out standard metallographic treatment on the test surface, and use 1000#~7000# sandpaper to polish; use the sample holder to clamp the sample for mechanical polishing; then fully clean the sample in alcohol and acetone spare.

[0061] (2) Electropolishing experiment preparation:

[0062] According to perchloric acid 7%, methanol 59%, n-butanol 34% (both volume ratio) configuration electrolytic electrolyt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com