Production method of rose-bengal ceramic pigment

A technology of ceramic pigments and production methods, which is applied in the direction of fibrous fillers, etc., can solve the problems of limiting the use of pigments, not bright enough colors, fading, etc., to meet the needs of color development and color matching, and reduce high-temperature glaze defects , Improve the effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

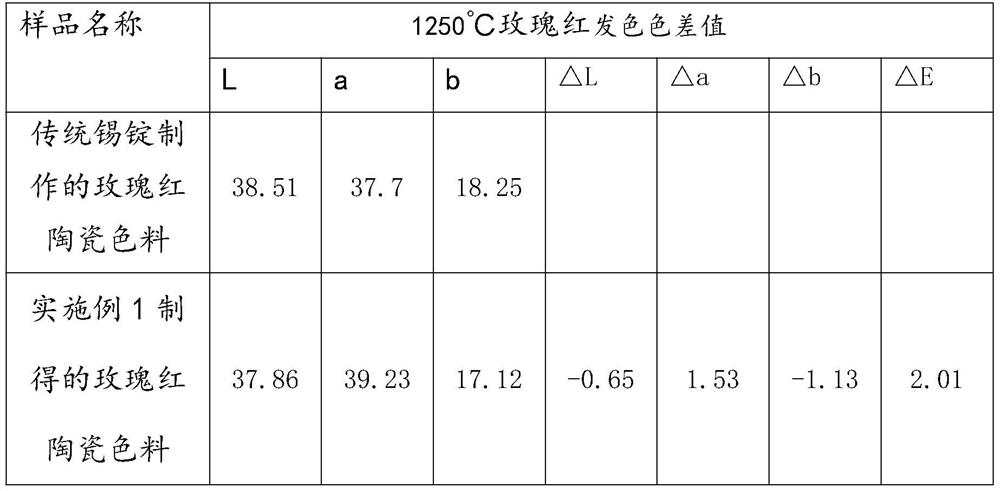

Examples

Embodiment approach

[0044] As a preferred embodiment, in the step 1, the raw material further includes borax or boric acid.

[0045] The above boric acid or borax plays a role in mineralization, and when combined with other components, it can ensure that the rose red material can be synthesized at the bottom temperature.

[0046] As a preferred embodiment, the raw materials in the step 1 are obtained by reacting the by-products generated in the fused zirconia production process in a stirring tank, and the by-products include soluble silicate solution and calcium oxide solution.

Embodiment 1

[0048] A kind of production method of rose red ceramic colorant, is characterized in that, comprises the following steps:

[0049] Step 1: Mix and grind the raw materials by wet method, the raw materials include: 55kg calcium silicate, 45kg tin oxide, 2%kg potassium dichromate, 3kg borax; in the grinding process, the raw materials: grinding balls: the quality of water The ratio is 1:1.5:0.4, and the grinding time is 1.5h; the raw materials are obtained by reacting the by-products generated in the fused zirconia production process in the stirring tank, and the by-products include soluble silicate solution and calcium oxide solution;

[0050] Step 2: The ground material is subjected to stale treatment at 25°C, and the stale time is 60h;

[0051] Step 3: drying the stale material at a drying temperature of 60°C;

[0052] Step 4: The dried material is sieved with a 30-mesh screen for use;

[0053] Step 5: Heating and calcining the sieved material for 9 hours, keeping at 1245°C f...

Embodiment 2

[0057] A kind of production method of rose red ceramic colorant, is characterized in that, comprises the following steps:

[0058] Step 1: the raw materials are mixed and ground by wet method, and the raw materials include: 50 kg of calcium silicate, 40 kg of tin oxide, 1 kg of potassium dichromate, and 1 kg of boric acid; in the grinding process, the mass ratio of raw materials: grinding balls: water It is 1:1.5:0.3, and the grinding time is 1h; the raw materials are obtained by reacting the by-products generated in the fused zirconia production process in the stirring tank, and the by-products include soluble silicate solution and calcium oxide solution;

[0059] Step 2: The ground material is subjected to stale treatment at 20°C, and the stale time is 50h;

[0060] Step 3: drying the stale material at a drying temperature of 50°C;

[0061] Step 4: The dried material is sieved with a 20-30 mesh screen for use;

[0062] Step 5: Heating and calcining the sieved material for 8h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com