A peeled marble tile with peeled glaze and no glaze defects and its preparation process

A preparation process and glaze peeling technology, which is applied in the field of peeling marble tiles and its preparation process, can solve the problems of foaming, dripping glaze, high fluidity, etc., achieve obvious depression effect, meet the thickness of glaze layer, and improve high temperature viscosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1-a kind of preparation technology that peels off marble tile without glaze surface defect, comprises the steps:

[0028] 1. Preparation of peeling glaze:

[0029] The raw material composition ratio of the peeling glaze is shown in the following table:

[0030] raw material Potassium feldspar Washed Ball Soil quartz wollastonite percentage 22% 4% 25% 26.41% raw material limestone Zinc oxide Corundum powder percentage 6% 6% 10%

[0031] After mixing the above raw materials, add 0.4% sodium tripolyphosphate, 0.12% medium viscous carboxymethyl fiber and 0.07% ethylene glycol for mixed ball milling to obtain a peeling glaze, wherein the specific gravity of the peeling glaze is 1.75, and the flow rate for 40s.

[0032] 2. Preparation steps for peeling off marble tiles:

[0033] (1) According to the pre-designed peeling texture, spray the peeling ink containing vanadium pentoxide on the surface of the brick;

...

Embodiment 2

[0036] Embodiment 2-a kind of preparation technology that peels off marble tile without glaze surface defect, comprises the steps:

[0037] 1. Preparation of peeling glaze:

[0038] The raw material composition ratio of the peeling glaze is shown in the following table:

[0039] raw material Potassium feldspar Washed Ball Soil quartz wollastonite percentage 18% 6% 30% 25.39% raw material limestone Zinc oxide Corundum powder percentage 5% 5% 10%

[0040] After mixing the above raw materials, add 0.5% sodium tripolyphosphate, 0.07% medium viscous carboxymethyl fiber and 0.04% ethylene glycol for mixed ball milling to obtain a peeling glaze, wherein the specific gravity of the peeling glaze is 1.80, and the flow rate for 35S.

[0041] 2. Preparation steps for peeling off marble tiles:

[0042] (1) According to the pre-designed peeling texture, spray the peeling ink containing vanadium pentoxide on the surface of the brick;

[...

Embodiment 3

[0045] Embodiment 3-a kind of preparation technology that peels off marble tile without glaze surface defect, comprises the steps:

[0046] 1. Preparation of peeling glaze:

[0047] The raw material composition ratio of the peeling glaze is shown in the following table:

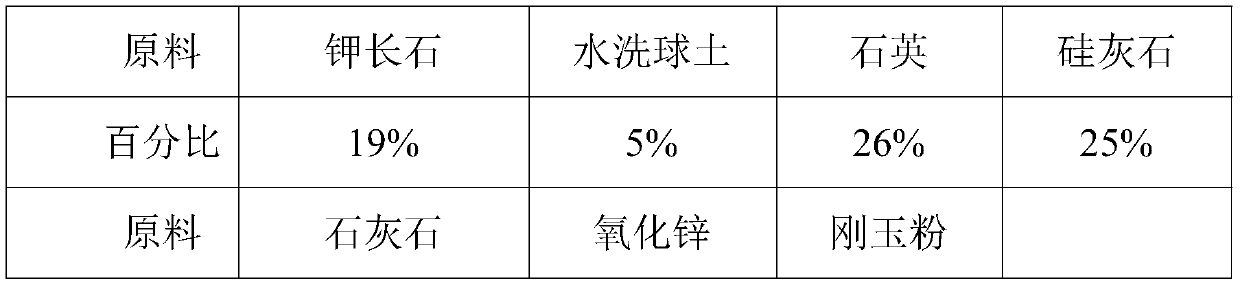

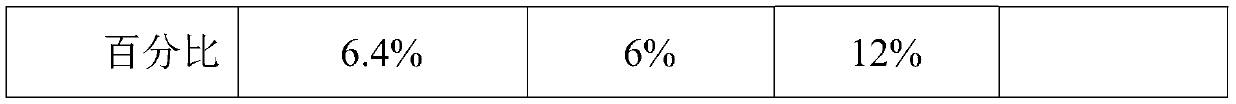

[0048]

[0049]

[0050] After mixing the above raw materials, add 0.45% sodium tripolyphosphate, 0.1% medium viscous carboxymethyl fiber and 0.05% ethylene glycol for mixed ball milling to obtain a peeling glaze, wherein the specific gravity of the peeling glaze is 1.78, and the flow rate is For 37S.

[0051] 2. Preparation steps for peeling off marble tiles:

[0052] (1) According to the pre-designed peeling texture, spray the peeling ink containing vanadium pentoxide on the surface of the brick;

[0053] (2) Spray peeling glaze on the surface of the brick adobe with peeling ink, wherein the temperature of the brick adobe before the peeling off glaze is 45°C, and the amount of glaze on the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com