Foamed ceramic with high sunlight reflection performance and thermal insulation and preparation method thereof

A foam ceramic and foam layer technology, applied in the field of ceramics, can solve the problems of low viscosity at high temperature, foaming, and low closed porosity, and achieve good antifouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

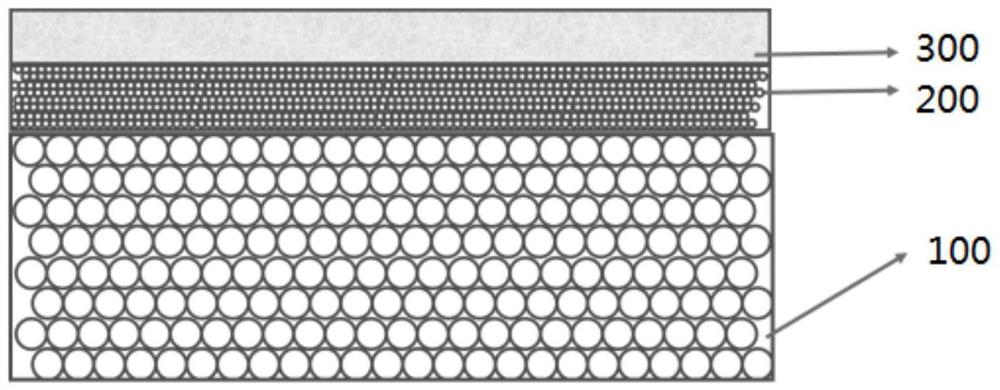

[0043] refer to figure 1 , a foam ceramic with high solar reflection performance and thermal insulation, comprising a foam layer 100, a dense layer 200 and a functional glaze layer 300 from bottom to top.

[0044] The preparation method of the foamed ceramics with high solar reflection performance and thermal insulation comprises the following steps:

[0045] S1. According to parts by weight, 15 parts of high alumina fly ash, 15 parts of waste glass powder, 8 parts of sand shale, 4 parts of quartz, 14 parts of potassium albite feldspar, 5 parts of talcum powder, 14 parts of borax, nitrogen 5 parts of silicon dioxide, 5 parts of calcium carbonate and 5 parts of magnesium carbonate were added into a ball mill tank and mixed and ball milled for 50 minutes to obtain a slurry, which was then spray-dried and homogenized to obtain the first mixture; wherein the spray-dried moisture control At 4.5%, the stale homogenization time is 40h;

[0046] S2. According to parts by weight, add...

Embodiment 2

[0051] A foam ceramic with high solar reflection performance and thermal insulation, comprising a foam layer, a dense layer and a functional glaze layer from bottom to top.

[0052] The preparation method of the foamed ceramics with high solar reflection performance and thermal insulation comprises the following steps:

[0053] S1. According to parts by weight, 14 parts of high alumina fly ash, 15 parts of waste glass powder, 19 parts of sand shale, 4 parts of quartz, 14 parts of potassium albite feldspar, 5 parts of talcum powder, 12 parts of borax, nitrogen Add 4 parts of silicon dioxide, 7 parts of calcium carbonate and 6 parts of magnesium carbonate into a ball mill tank for mixing and ball milling for 45 minutes to obtain a slurry, which is then spray-dried and homogenized to obtain the first mixture; wherein the spray-dried moisture control At 5.5%, the stale homogenization time is 40h;

[0054] S2. According to parts by weight, 34 parts of high-alumina fly ash, 43 part...

Embodiment 3

[0059] A foam ceramic with high solar reflection performance and thermal insulation, comprising a foam layer, a dense layer and a functional glaze layer from bottom to top.

[0060] The preparation method of the foamed ceramics with high solar reflection performance and thermal insulation comprises the following steps:

[0061] S1. According to parts by weight, 15 parts of high alumina fly ash, 15 parts of waste glass powder, 8 parts of sand shale, 4 parts of quartz, 14 parts of potassium albite feldspar, 5 parts of talcum powder, 14 parts of borax, nitrogen 5 parts of silicon dioxide, 5 parts of calcium carbonate and 5 parts of magnesium carbonate were added into a ball mill tank and mixed and ball milled for 50 minutes to obtain a slurry, which was then spray-dried and homogenized to obtain the first mixture; wherein the spray-dried moisture control At 5%, the stale homogenization time is 37h;

[0062] S2. According to parts by weight, 34 parts of high-alumina fly ash, 43 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com