Black pigment for ceramic ink-jet printing and preparation method and application thereof

A black pigment and ceramic inkjet technology, applied in the field of ceramic pigments, can solve problems such as unstable color development, achieve the effects of improving glaze defects, increasing crystallinity, improving color development performance and glaze defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

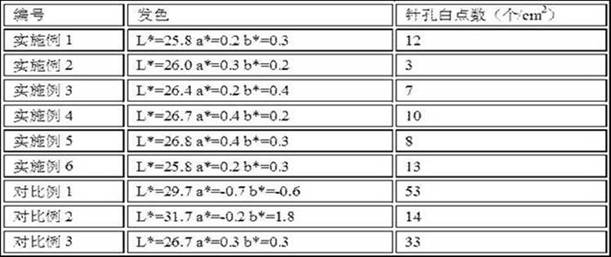

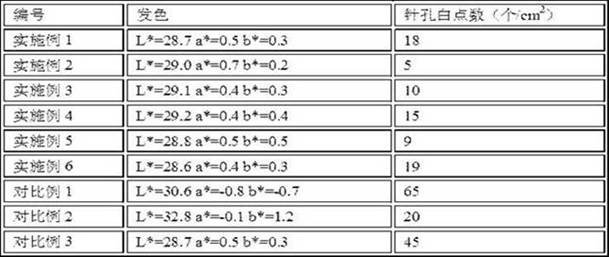

Examples

Embodiment 1

[0044] A kind of preparation method of black pigment for ceramic inkjet printing of the present embodiment, comprises the following steps:

[0045] Step 1, the preparation of calcined material: the Cr 2 o 3 and Fe 2 o 3 Press m(Cr 2 o 3 ):m(Fe 2 o 3 )=2.0 for batching, put it in a mixer and stir evenly, then put it in a pusher kiln for firing, the firing temperature is 1220°C, the holding time is 9h, and then the prepared powder is crushed with a powder machine , until the fineness is 325 mesh full pass or smaller fineness, to obtain calcined material.

[0046] Step 2, the preparation of colorant: carry out batching with calcined material and remaining raw material according to formula, the weight parts of each raw material are as follows: calcined material is 27 parts, Co 3 o 4 27.5 parts for NiO, 30 parts for NiO, MnO 2 5 parts, Al 2 o 3 4 parts, SrCO 3 for 3 copies, Bi 2 o 3 For 2 parts, MoO 3 It is 1.5 parts. Put the ingredients in the mixer and stir them eve...

Embodiment 2

[0048] A kind of preparation method of black pigment for ceramic inkjet printing of the present embodiment, comprises the following steps:

[0049] Step 1, the preparation of calcined material: the Cr 2 o 3 and Fe 2 o 3 Press m(Cr 2 o 3 ):m(Fe 2 o 3 )=1.9 for batching, put it in a mixer and stir evenly, then put it in a pusher kiln for firing, the firing temperature is 1260°C, the holding time is 6.5h, and then the prepared powder is crushed with a powder machine Processing, until the fineness is 325 mesh all-through, to obtain calcined material.

[0050] Step 2, the preparation of colorant: carry out batching with calcined material and remaining raw material according to formula, the weight parts of each raw material are as follows: calcined material is 33.8 parts, Co 3 o 4 27.5 parts, NiO 30 parts, Al 2 o 3 4 parts, SrCO 3 1.2 parts, Bi 2 o 3 For 2 parts, MoO 3 It is 1.5 parts. Put the ingredients in a mixer and stir evenly, then put them in a pusher kiln for ...

Embodiment 3

[0052] A kind of preparation method of black pigment for ceramic inkjet printing of the present embodiment, comprises the following steps:

[0053] Step 1, the preparation of calcined material: the Cr 2 o 3 and Fe 2 o 3 Press m(Cr 2 o 3 ):m(Fe 2 o 3 )=2.1 for batching, put it in a mixer and stir evenly, then put it in a pusher kiln for firing, the firing temperature is 1230°C, the holding time is 6h, and then the prepared powder is crushed with a powder machine , until the fineness is 325 mesh full pass or smaller fineness, to obtain calcined material.

[0054] Step 2, the preparation of colorant: carry out batching with calcined material and remaining raw material according to formula, the weight parts of each raw material are as follows: calcined material is 17 parts, Co 3 o 4 32.3 parts for NiO, 45 parts for NiO, MnO 2 2 parts, SrCO 3 2.2 parts, Bi 2 o 3 For 1 part, MoO 3 0.5 parts, put the ingredients in a mixer and stir evenly, then put them in a pusher kiln...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com