Method for performing surface modification on carbon-based material through metal slurry

A carbon-based material and surface modification technology, which is applied in the field of materials, can solve the problems of low bonding strength between the surface chromium coating and the substrate, large differences in expansion coefficient and elastic modulus, and difficult liquid metal wetting of carbon-based materials. Achieve the effects of easy quality control, firm metallurgical bonding, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Weigh the chromium powder, place it in a roller ball mill, use cemented carbide balls or agate balls as the grinding balls, and alcohol as the ball milling medium, and the ball milling is greater than or equal to 8 hours;

[0023] (2) Place the above metal mixed powder in a vacuum oven at 100°C for drying;

[0024] (3) Get a certain amount of metal chromium powder after ball milling and drying, add an appropriate amount of organic binder, use a glue homogenizer to fully mix to obtain a uniform slurry;

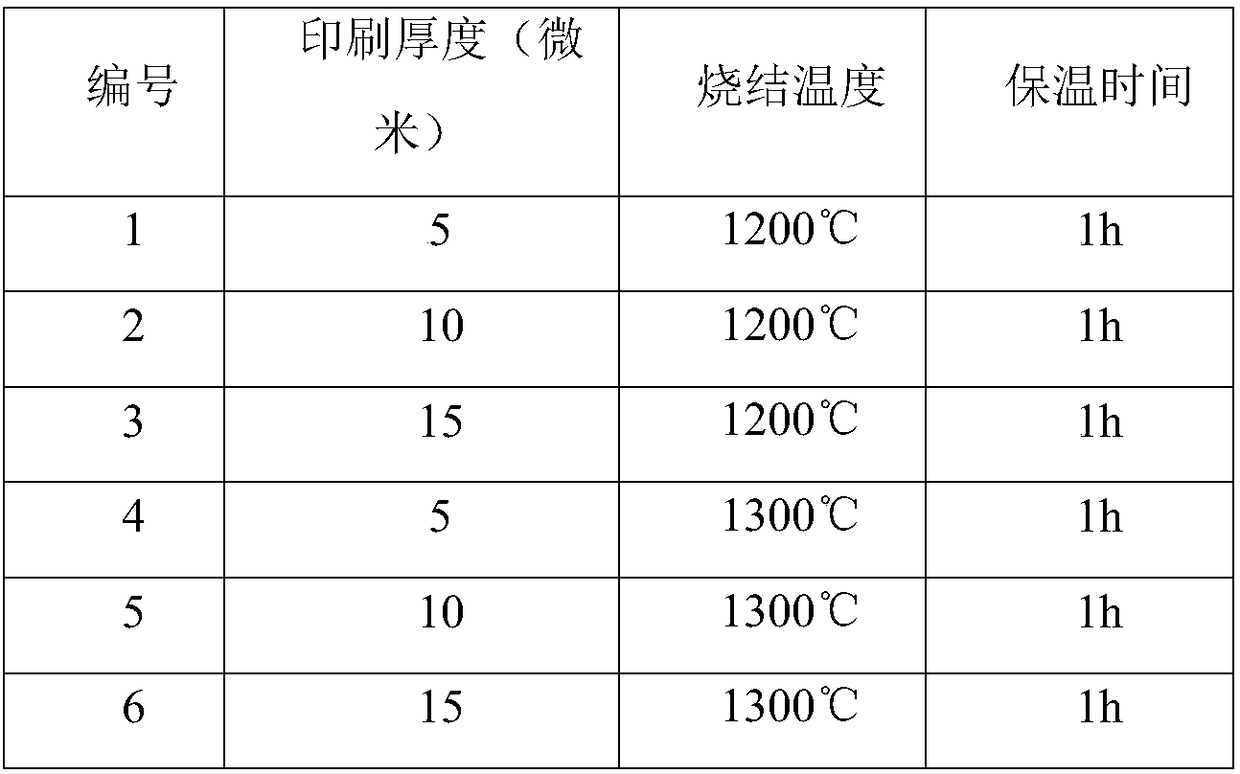

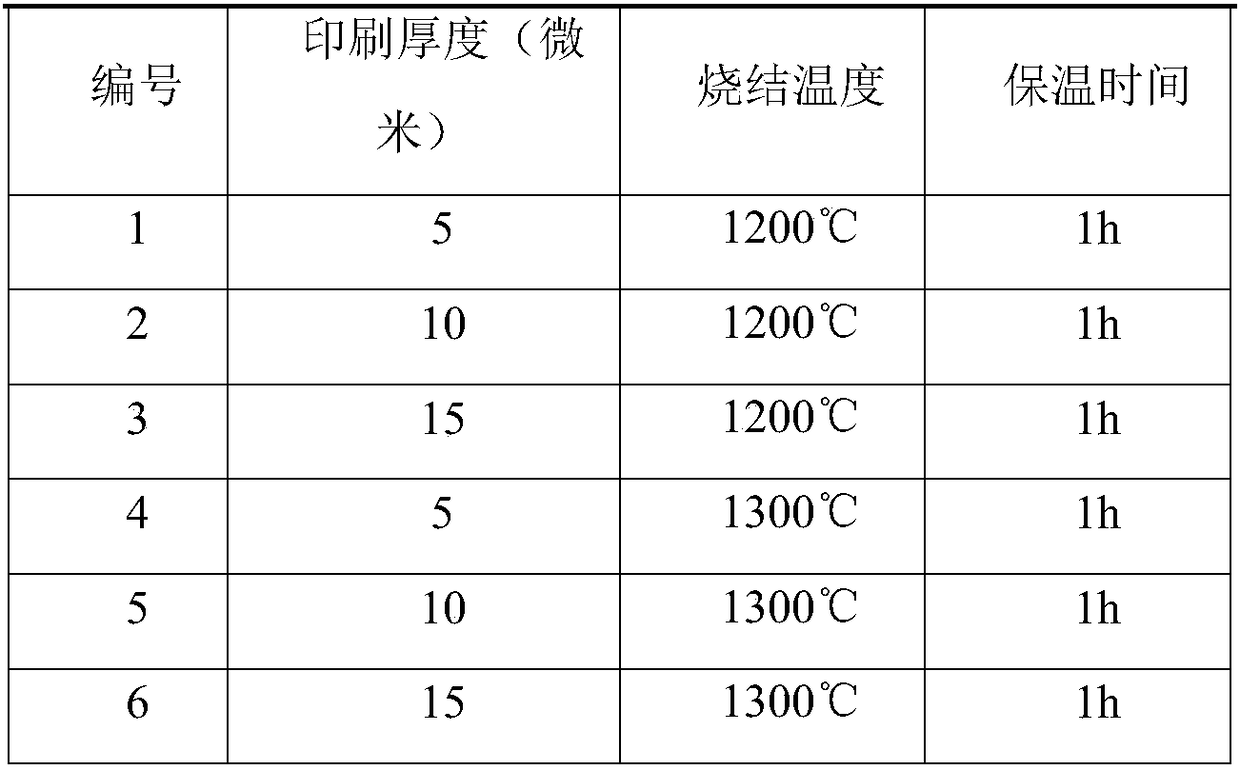

[0025] (4) Adjust the gap between the screen printing machine screen and graphite and the specifications of the screen, and print samples with different thicknesses (5 microns, 10 microns and 15 microns);

[0026] (5) Put the printed sample in a vacuum furnace, take a certain temperature and a certain holding time, so that the metal chromium powder can fully react with the graphite, and then cool down at a certain cooling rate to form a dense metal coating . The sp...

Embodiment 2

[0030] (1) Weigh the chromium powder, place it in a roller ball mill, use cemented carbide balls or agate balls as the grinding balls, and alcohol as the ball milling medium, and the ball milling is greater than or equal to 8 hours;

[0031] (2) Place the above metal mixed powder in a vacuum oven at 100°C for drying;

[0032] (3) Get a certain amount of metal chromium powder after ball milling and drying, add an appropriate amount of organic binder, use a glue homogenizer to fully mix to obtain a uniform slurry;

[0033] (4) Adjust the gap between the screen printing machine screen and the carbon fiber reinforced carbon matrix composite material and the specifications of the screen, and print samples with different thicknesses (5 microns, 10 microns and 15 microns);

[0034] (5) Put the printed sample in a vacuum furnace, take a certain temperature and a certain holding time, so that the metal chromium powder can fully react with the carbon fiber-reinforced carbon-based compos...

Embodiment 3

[0038] A method for modifying the surface of a carbon-based material by using a metal slurry method is carried out according to the following steps:

[0039] (1) The chromium powder is weighed, placed in a roller ball mill, with cemented carbide balls or agate balls as the grinding balls, alcohol as the ball milling medium, the ball milling is greater than or equal to 8 hours, and the purity of the chromium is 99.99%;

[0040] (2) Place the above metal mixed powder in a vacuum oven at 100°C for drying;

[0041] (3) Take a certain amount of metal chromium powder after ball milling and drying, add an appropriate amount of organic binder, and use a glue homogenizer to fully mix to obtain a uniform slurry. The organic binder is terpineol + ethyl fiber Plain solution, and terpineol: ethyl cellulose: metallic chromium powder=4; 1; 6;

[0042] (4) The slurry is printed on the surface of the pretreated carbon-based material by screen printing technology, and the thickness of the phot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com