Fluororubber molded article

A fluororubber and molded product technology, applied in the field of fluororubber molded products, can solve the problems of poor softness of metallic luster film layer, peeling of metallic luster film layer, damaged flexibility of silicone rubber products, etc. Low odor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

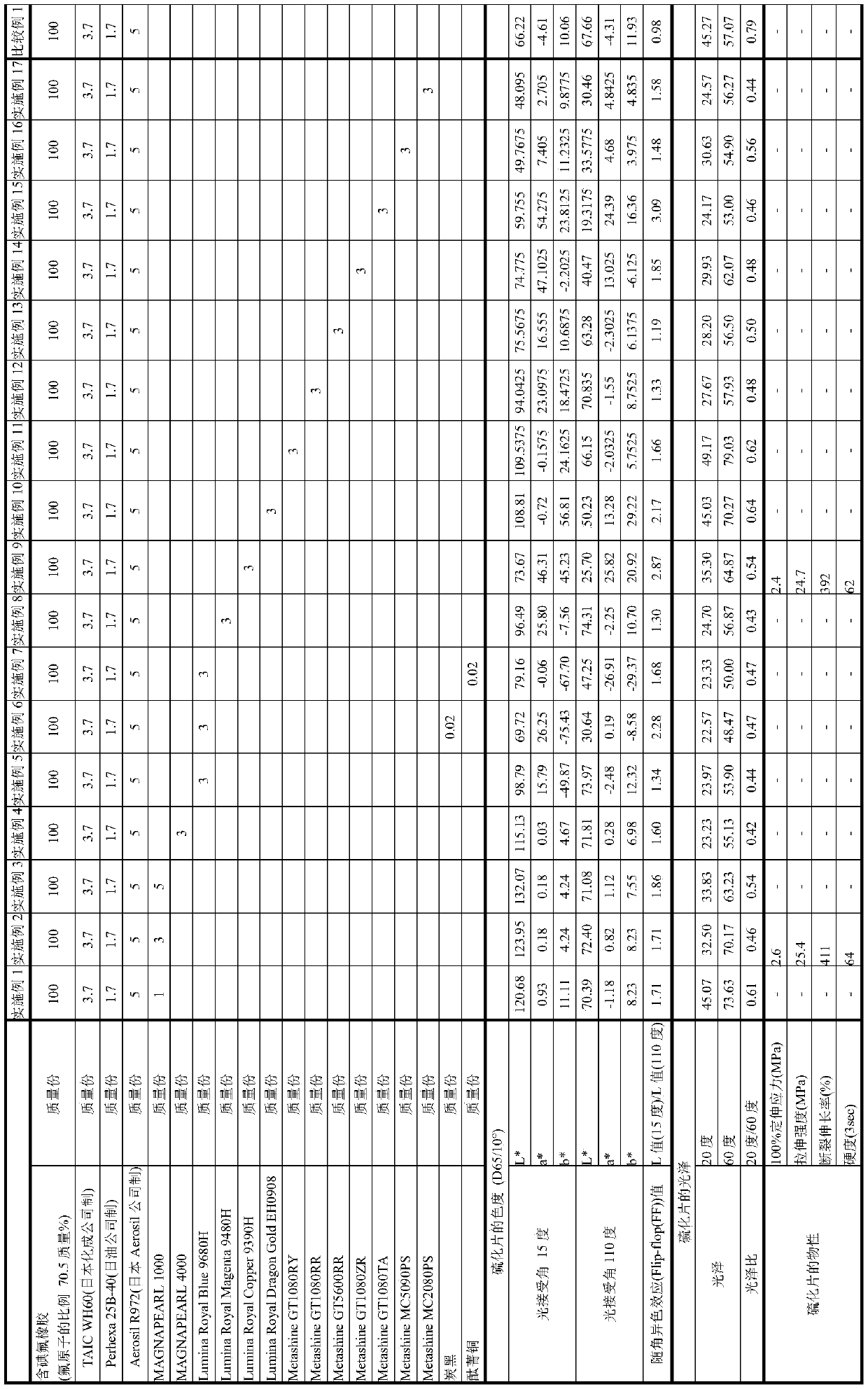

Embodiment 1~17 and comparative example 1

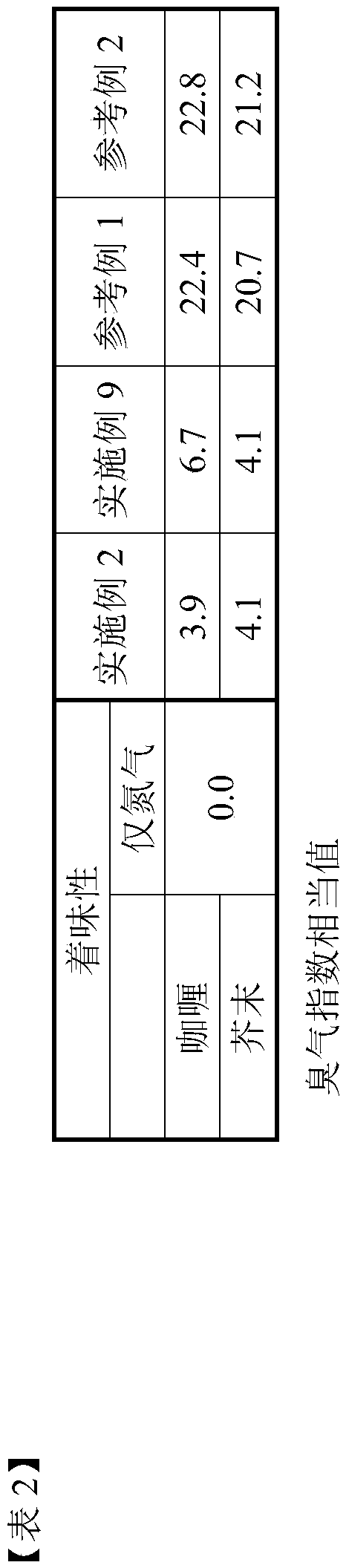

[0127] A bright fluororubber mixture containing iodine-containing fluororubber (VDF / TFE / HFP copolymer) capable of peroxide crosslinking was prepared according to the formula described in Table 1 using a rubber roller. The obtained mixture was press-molded at 170° C. for 6 minutes into a sheet having a thickness of 1 mm, a length of 100 mm, and a width of 100 mm. Furthermore, as secondary vulcanization, it heated at 180 degreeC for 2 hours in an oven. The specular surface of the sheet was measured. In addition, the molded sheets obtained in Examples 2 and 9 were evaluated for taste, and the results are shown in Table 2.

reference example 1

[0129] 3 parts by mass of MAGNAPEARL 1000 (manufactured by BASF Color & Effects) was added to 100 parts by mass of a silicone rubber compound (SH841U, manufactured by Dow Corning Toray) to prepare a rubber mixture. The obtained mixture was molded into a sheet having a thickness of 1 mm, a length of 100 mm, and a width of 100 mm, and subjected to secondary vulcanization to obtain a silicone rubber molded sheet. Table 2 shows the evaluation results of flavor property.

reference example 2

[0131] A silicone rubber molding sheet was obtained in the same manner as in Reference Example 1, except that 3 parts by mass of Lumina Royal Copper 9390H (manufactured by BASF Color & Effects) was added to 100 parts by mass of the silicone rubber compound (SH841U, manufactured by Dow Corning Toray). Table 2 shows the evaluation results of flavor property.

[0132] In each example, the following bright pigments manufactured by BASF Color & Effects were used.

[0133] Titanium oxide coated mica

[0134] MAGNAPEARL 1000

[0135] MAGNAPEARL 4000

[0136] Lumina Royal Blue 9680H

[0137] Lumina Royal Magenta 9480H

[0138] Iron oxide coated mica

[0139] Lumina Royal Copper 9390H

[0140] Mixture of mica coated with titanium oxide and mica coated with iron oxide

[0141] Lumina Royal Dragon Gold EH0908

[0142] Titanium oxide coated glass flakes

[0143] Metashine GT1080RY

[0144] Metashine GT1080RR

[0145] Metashine GT5600RR

[0146] Iron oxide coated glass flakes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com