Polyurethane building wall edge and corner coating and production method thereof

A technology for architectural coatings and polyurethanes, applied in polyurea/polyurethane coatings, anti-corrosion coatings, antifouling/underwater coatings, etc., can solve problems such as easy water leakage, prolong the life of the paint film, prevent cracks, water resistance and mechanical mechanics good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Add 5 parts of water, 10 parts of titanium dioxide, 7 parts of water-soluble chitosan (molecular weight 50,000), 9 parts of additives (including 1 part of chain extender, 2 parts of leveling agent, and 3 parts of dispersant) in the mixer , 1 part of thickener, 0.5 part of bactericidal antifungal agent, 0.5 part of defoamer, 1 part of dustproof agent), 12 parts of filler (ultrafine talcum powder: mica powder = 1:1), stir well, and mix the obtained The solution is ground by a sander to a particle size of less than 40 microns, and then the solution is put back into the mixer, and 3 parts of adhesion promoter, 50 parts of water-curable polyurethane, 15 parts of water-based acrylic resin, and 9 parts of dimethyl carbonate are mixed into it. Stir well.

Embodiment 2

[0047] Add 8 parts of water, 6 parts of titanium dioxide, 9 parts of water-soluble chitosan (molecular weight 30,000), 13 parts of additives (including 3 parts of chain extender, 2 parts of leveling agent, and 1 part of dispersant) in the mixer , 3 parts of thickener, 0.5 part of bactericidal antifungal agent, 1.5 parts of defoamer, 2 parts of dustproof agent), 16 parts of filler (ultrafine talcum powder: mica powder = 1:1), stir well, and mix the obtained The solution is ground by a sander until the particle size is within 40 microns, and then the solution is put back into the mixer, and 7 parts of adhesion promoter, 45 parts of water-curable polyurethane and 25 parts of water-based acrylic resin are put into it, and 8 parts of dimethyl carbonate are mixed. Stir well.

Embodiment 3

[0049] Add 6 parts of water, 7 parts of titanium dioxide, 5 parts of water-soluble chitosan (molecular weight 20,000), 8 parts of additives (including 1 part of chain extender, 1 part of leveling agent, and 2 parts of dispersant) in the mixer , 1 part of thickener, 1 part of bactericidal antifungal agent, 1 part of defoamer, 1 part of dustproof agent), 14 parts of filler (ultrafine talcum powder: mica powder = 1:1), stir well, and mix the obtained The solution is ground by a sander until the particle size is within 40 microns, and then the solution is put back into the mixer, and 5 parts of adhesion promoter, 40 parts of water-curable polyurethane and 20 parts of water-based acrylic resin are put into it, and 10 parts of dimethyl carbonate are mixed. Stir well.

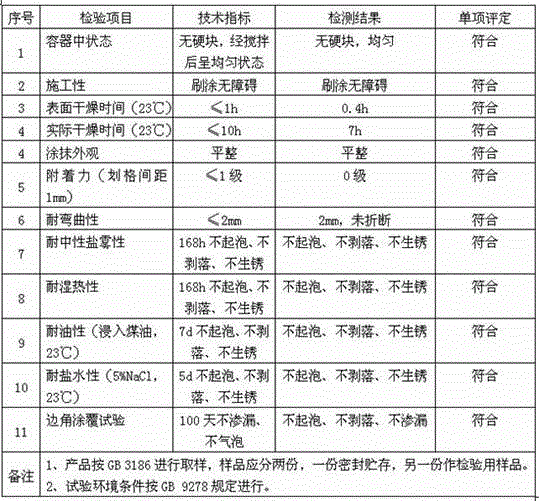

[0050] According to GB / T1723-93, GB / T 1724-89, GB / T 1731-93, GB / T 1732-93, GB / T1733-93, GB / T 1734-93 standards, the results are listed in the table below.

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com