Hollow type plate illuminating device

A lighting device, hollow technology, applied in the direction of lighting device, lighting device parts, lighting and heating equipment, etc., can solve the problem of not being able to emit a large amount of white light, and achieve bright, light and uniform effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

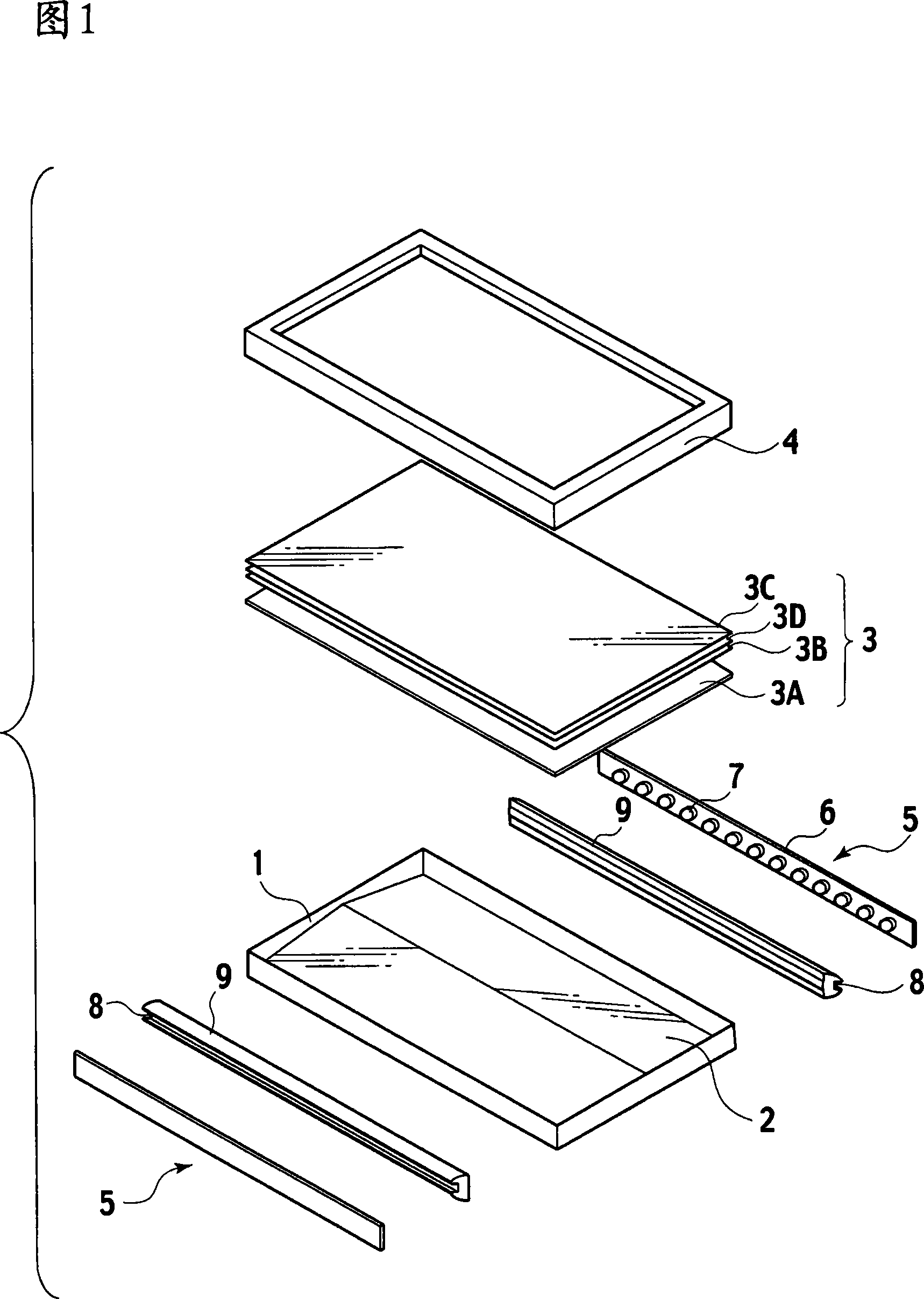

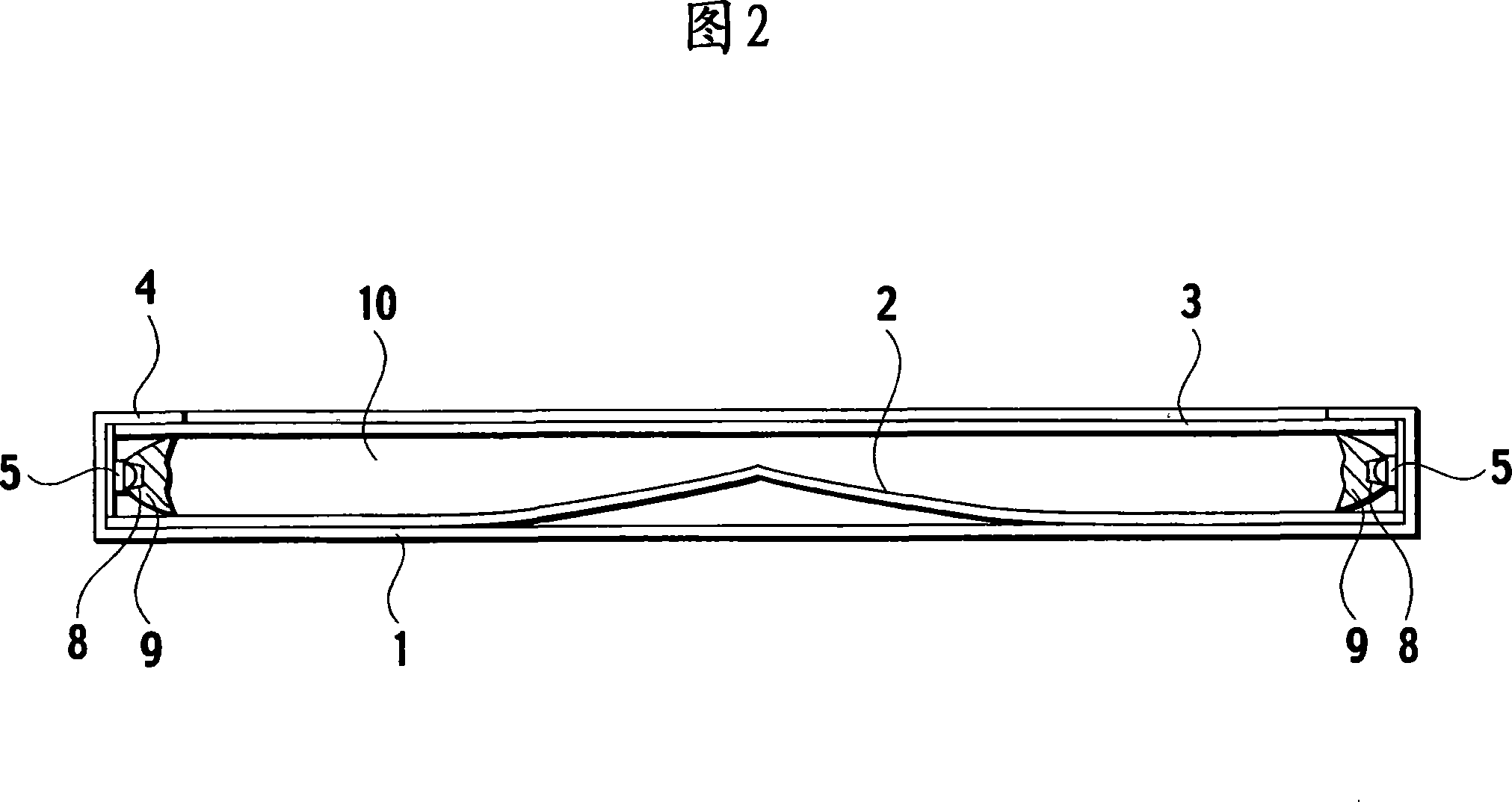

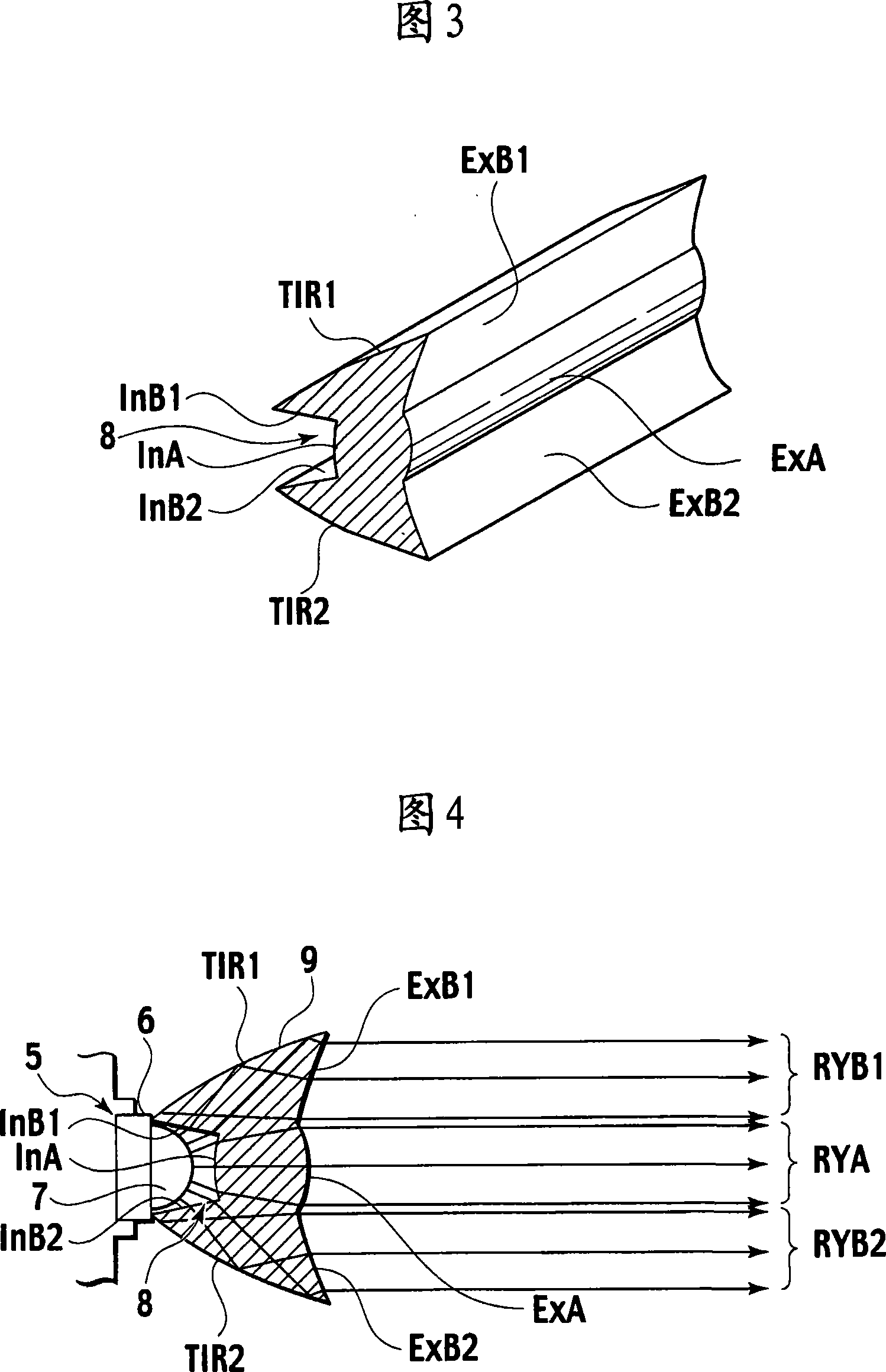

[0029] 1 and 2 show a hollow type flat panel lighting device according to a first embodiment of the present invention, which is used as a backlight unit of an LCD. The backlight unit has a housing 1 . At the bottom of the housing 1 a reflector 2 is arranged. The reflector 2 has a central ridge extending parallel to the sides of the housing 1 . The reflector 2 descends gradually from the ridge towards each side of the housing 1 . At the top of the housing 1 a light emitting surface part 3 is arranged. The light emitting surface part 3 is covered with a front frame 4 which is fixed to the housing 1 to form the backlight unit of the first embodiment. The space between the reflector 2 and the light-emitting surface part 3 in the housing 1 defines a light-guiding space 10 .

[0030] The reflector 2 is made of a substrate and a material with high reflectivity and scattering rate on the substrate, and the substrate is made of resin or metal. Highly reflective and scattering mate...

no. 2 example

[0040] A backlight unit according to a second embodiment of the present invention will be described with reference to FIGS. 6 and 7 . The backlight unit of the second embodiment is characterized by a collimator 9A shown in FIGS. 6 and 7 . The collimator 9A has the same shape as the collimator 9 of the first embodiment shown in FIGS. 1 and 2 . The collimator 9A differs from the collimator 9 in that the groove 8A of the collimator 9A has incident surfaces InA, InB1 and InB2 each having a prism. Other parts of the backlight unit according to the second embodiment are the same as those of the backlight unit according to the first embodiment shown in FIGS. 1 and 2 .

[0041] In FIG. 7 , the light from the LEDs 7 on the LED bar 5 enters the interior of the collimator 9A through the incident surfaces InA, InB1 and InB2 of the groove 8A of the collimator 9A. The prisms on these entrance faces effectively scatter the incident light passing through the body of the collimator 9A. The ...

no. 3 example

[0044] A backlight unit according to a third embodiment of the present invention will be described with reference to FIGS. 8 and 9 . The backlight unit of the third embodiment is characterized by a collimator 9B shown in FIGS. 8 and 9 . The collimator 9B has the same shape as the collimator 9 of the first embodiment shown in FIGS. 1 and 2 . The collimator 9B differs from the collimator 9 in that each end of the groove 8B of the collimator 9B is terminated with an end face to form an end incident face InC. In addition, each end is provided with a total reflection end surface TIR3. Other parts of the backlight unit according to the third embodiment are the same as those of the backlight unit according to the first embodiment shown in FIGS. 1 and 2 .

[0045] In FIG. 9, the light from the LEDs 7 on the LED bar 5 is incident on the incident faces InA, InB1 and InB2 of the groove 8B of the collimator 9B. At the same time, light is incident on the incident surface InC at each end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com