Implementation process of highlight silver three-dimensional pattern

A pattern and silver technology, which is applied in the field of high-gloss silver three-dimensional pattern realization technology, can solve the problems that the marked pattern has no three-dimensional effect, the pattern has no highlight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] A process for realizing a high-gloss silver three-dimensional pattern, comprising the following steps:

[0018] Step 1. Choose a transparent injection molded product. The back of the transparent injection molded product is flat and the front is convex, and a concave marking pattern is printed on the back of the transparent injection molded product;

[0019] Step 2. Print on the back of the above-mentioned transparent injection molded product, and print all parts except the marked pattern;

[0020] Step 3: Carry out UV primer spraying on the marking pattern on the back of the above-mentioned transparent injection molded product;

[0021] Step 4, vacuum electroplating aluminum on the back of the above-mentioned transparent injection molded product;

[0022] Step 5, UV coating is carried out on the marking pattern on the back of the above-mentioned transparent injection molded product.

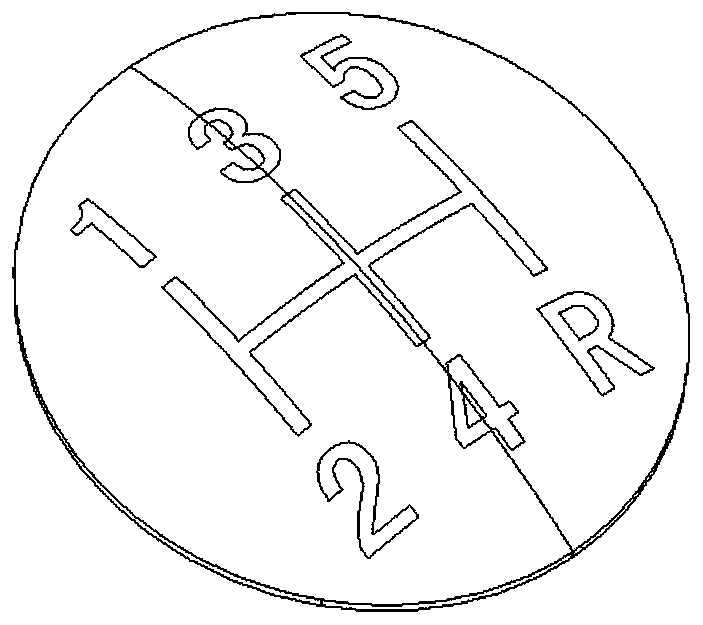

[0023] Such as figure 1 It is a front view of a product manufactured by an existing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com