Portable plastic fence L-shaped connecting mechanism

A connection mechanism and a convenient technology, which is applied in the direction of fences, building types, buildings, etc., can solve the problems of large volume, short service life, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

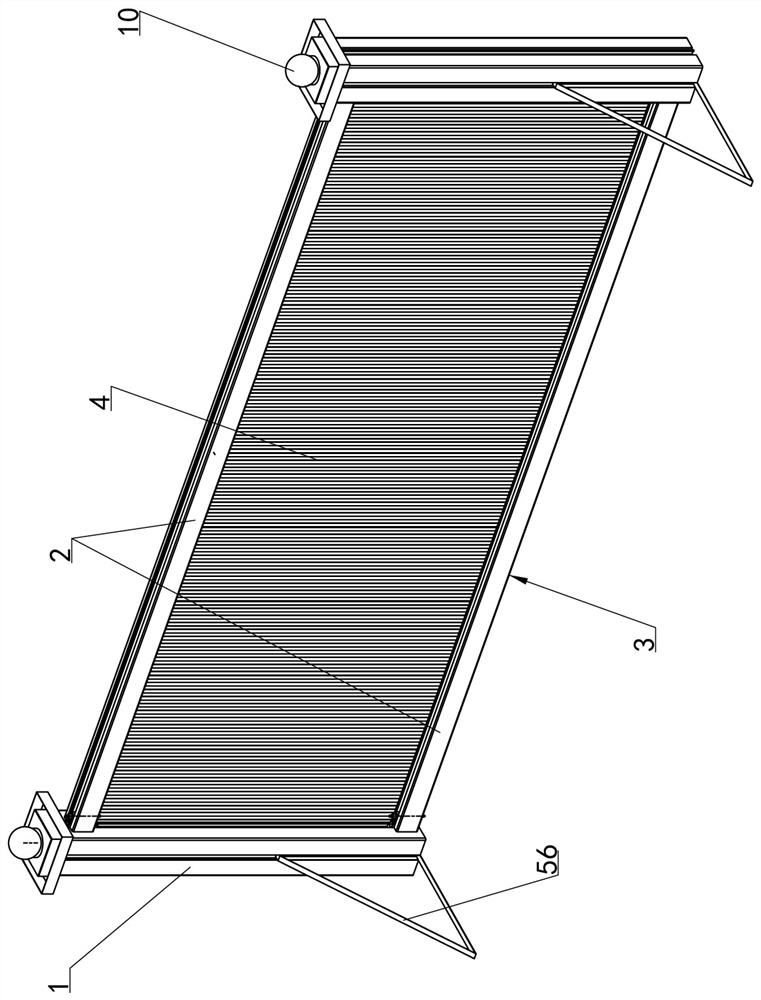

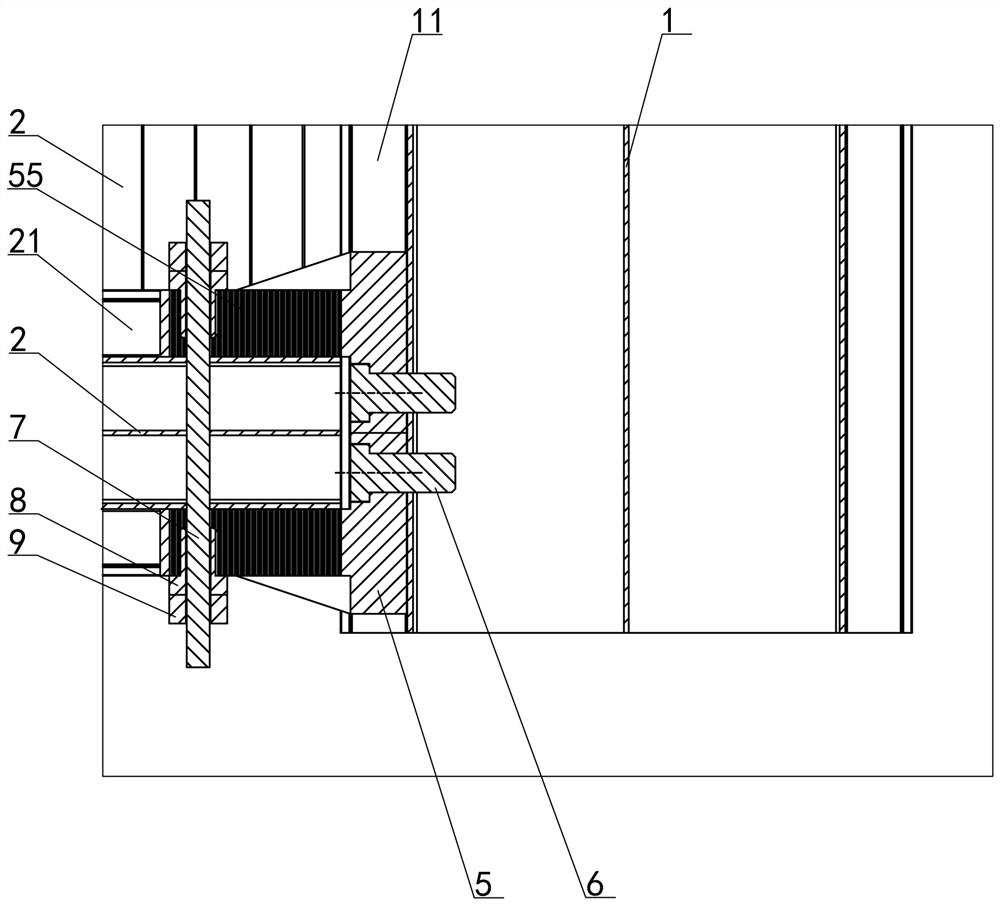

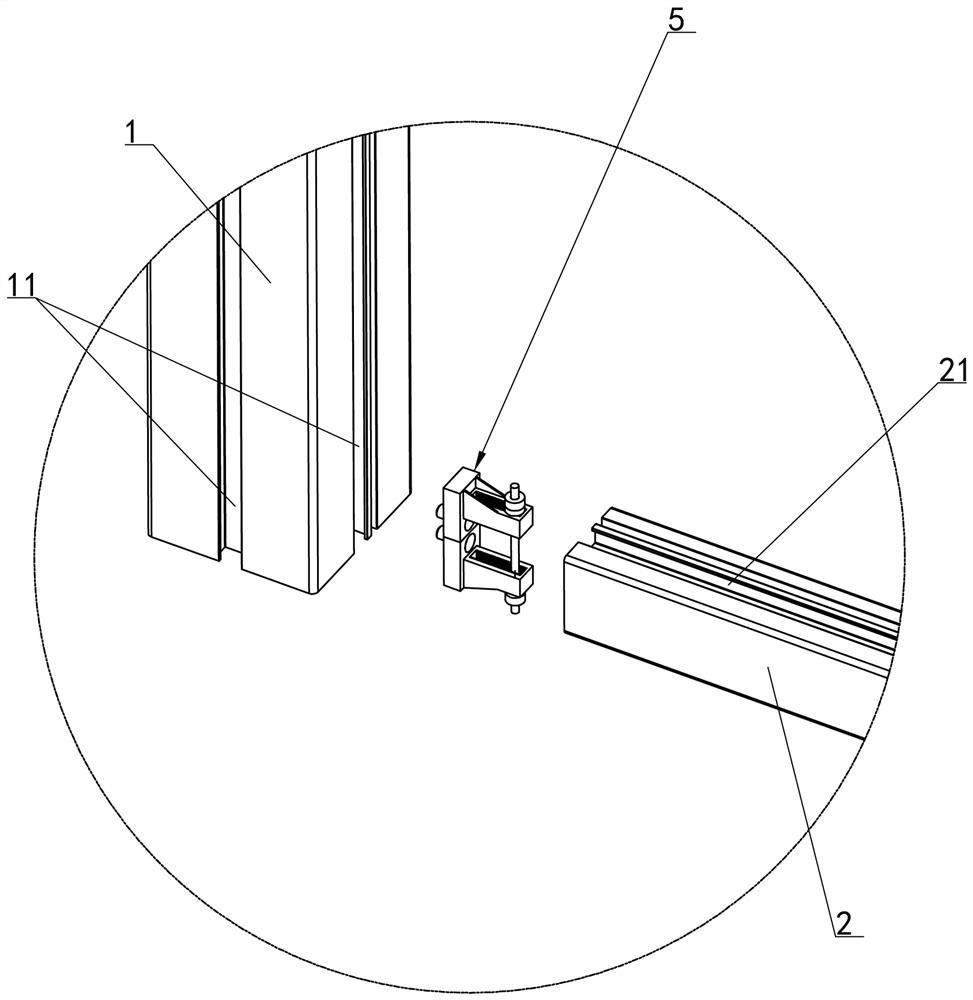

[0012] The invention relates to a convenient L-shaped connection mechanism for plastic enclosures, such as figure 1 — Figure 5 As shown, it includes an enclosure frame 3 composed of two columns 1 and two crosspieces 2 processed by plastic profiles, an enclosure plate 4 is arranged in the enclosure frame 3, and the two columns 1 and two crosspieces 2 A connecting mechanism is arranged between the four corners, and the connecting mechanism is an L-shaped connecting mechanism, which includes an L-shaped connecting seat 5, and one side of the L-shaped connecting seat 5 is provided with an L-shaped side edge 51, and on the L-shaped side edge 51 Fixing hole 52 is set, and the other side of L-shaped connection seat 5 is provided with rectangular bar 53, and through groove 54 is set on rectangular bar 53, and vertical groove 11 is all set on the three walls of described upright column 1, and the crosspiece 2 Horizontal grooves 21 are arranged on the upper and lower walls, and an L-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com