Preparation method of nano-bamboo charcoal antibacterial fibers for pets

A nano-bamboo charcoal, antibacterial fiber technology, applied in the direction of single-component polyolefin rayon, single-component polyamide rayon, single-component polyester rayon, etc., can solve cracking, easily contaminated bacteria, clothing Wear and other problems, to achieve the effect of expanding molecular spacing, excellent adsorption, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of antibacterial fiber:

[0035] (1) Pretreatment: Add nano-bamboo charcoal powder into deionized water, stir for 20 minutes under ultrasonic conditions, filter, dry to constant weight, and set aside;

[0036] (2) Preparation of antibacterial masterbatch: 15g nanometer bamboo charcoal powder, 10g nanometer silver powder, 80g carrier chip, 0.4g antioxidant, 2g dispersant, 0.4g active additive are mixed and stirred evenly, then sent in the twin-screw extruder, Carry out mixing and pelletizing to make the required antibacterial masterbatch, the mixing temperature is 250°C, the pressure inside the extruder is 7MPa, and the mixing speed is 300 rpm;

[0037] (3) Preparation of antibacterial fiber: mix and stir 2g antibacterial masterbatch and 90g carrier chips, melt and compound spinning, cooling, rolling, drafting, and shaping to make the required fiber, and the temperature of melt spinning is 270 ℃, cooling blowing temperature 24 ℃, wind speed 1 m / s, relative h...

Embodiment 2

[0044] Preparation of antibacterial fiber:

[0045] (1) Pretreatment: Add nano-bamboo charcoal powder into deionized water, stir for 20 minutes under ultrasonic conditions, filter, dry to constant weight, and set aside;

[0046] (2) Preparation of antibacterial masterbatch: 20g nanometer bamboo charcoal powder, 8g nanometer silver powder, 80g carrier chip, 0.4g antioxidant, 2g dispersant, 0.4g active additive are mixed and stirred evenly, then send into twin-screw extruder, Carry out mixing and pelletizing to make the required antibacterial masterbatch, the mixing temperature is 250°C, the pressure inside the extruder is 7MPa, and the mixing speed is 300 rpm;

[0047](3) Preparation of antibacterial fiber: 4g antibacterial masterbatch and 90g carrier chips are mixed and stirred, and the required fiber is made through melt composite spinning, cooling, rolling, drafting, and shaping, and the temperature of melt spinning is 270 ℃, cooling blowing temperature 24 ℃, wind speed 1 m...

Embodiment 3

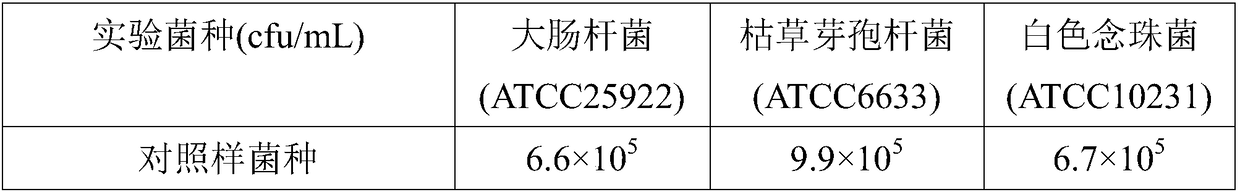

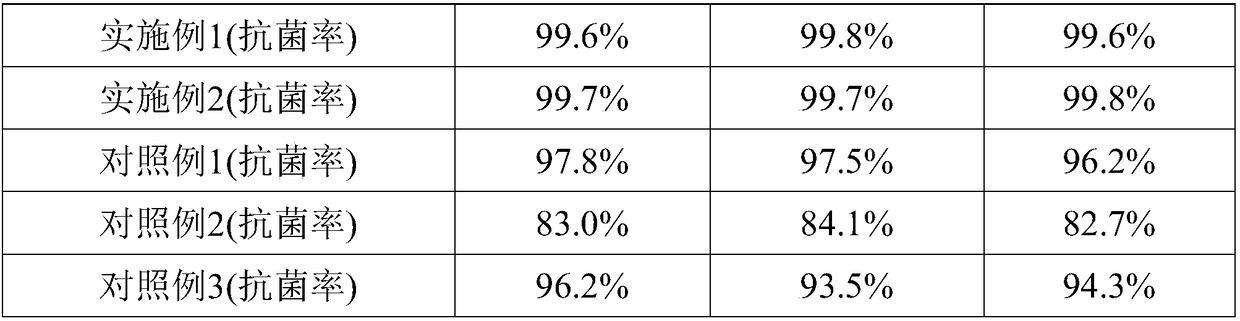

[0083] Based on Example 1, Comparative Example 1 without adding castor oil, Comparative Example 2 without modifying starch, and Comparative Example 3 without adding glyceryl monostearate were set.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com