Nanofiber and preparation method thereof

A nanofiber, nanoscale technology, applied in the direction of fiber chemical characteristics, cellulose/protein conjugated rayon, conjugated rayon, etc., can solve the effect of fiber antibacterial persistence, affect fiber mechanical properties, and large fiber diameter. and other problems, to achieve good antibacterial properties, improve dispersibility, and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

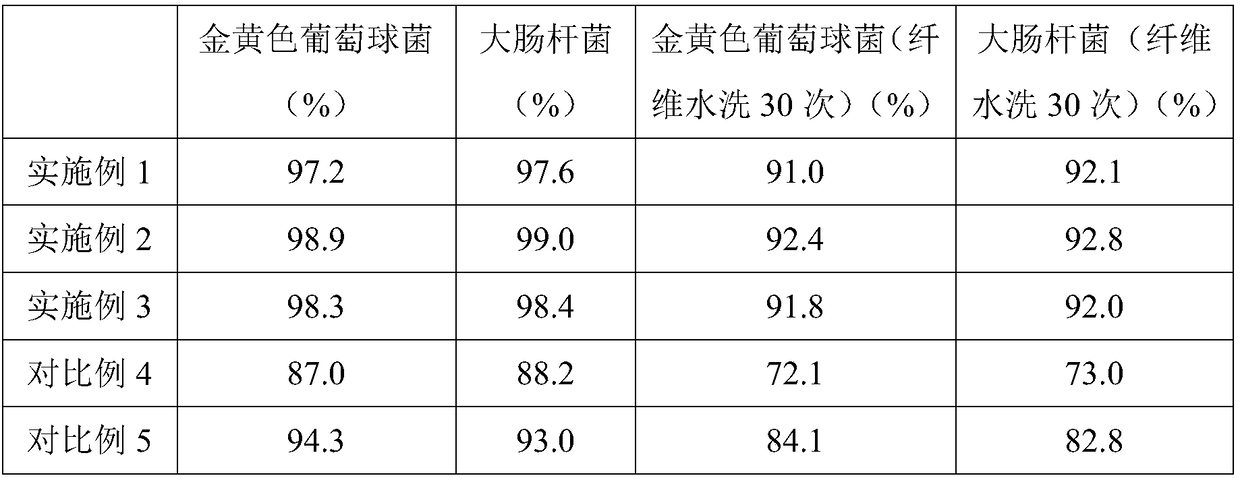

Examples

Embodiment 1

[0015] A method for preparing nanofibers, comprising the following steps,

[0016] (1) Coupling agent KH560 and nano-sized titanium dioxide are uniformly mixed at 50°C in the presence of a certain solvent dimethylformamide;

[0017] (2) Chitosan is added in the formic acid solution, stirred and mixed evenly at room temperature, then added silk protein, soybean protein solution, stirred evenly;

[0018] (3) Add polylactic acid to the solution of step (2), mix well, and then mix it with the solution of step (1) at 60°C;

[0019] (4) Pass the obtained solution through a syringe to spray the spinning solution from the spinneret, and collect it on a collecting plate to obtain nanofibers.

[0020] Spinning process parameters: the AC voltage is 10kV, and the distance from the spinneret to the collecting plate is 15cm.

[0021] The parts by mass of each component are: chitosan 50, silk protein 40, soybean protein 27, polylactic acid 20, nanoscale titanium dioxide 15, dimethylformami...

Embodiment 2

[0023] A method for preparing nanofibers, comprising the following steps,

[0024] (1) Coupling agent KH560 and nano-sized titanium dioxide are uniformly mixed at 60°C in the presence of a certain solvent dimethylformamide;

[0025] (2) Chitosan is added in the formic acid solution, stirred and mixed evenly at room temperature, then added silk protein, soybean protein solution, stirred evenly;

[0026] (3) Add polylactic acid to the solution of step (2), mix well, and then mix it with the solution of step (1) at 60°C;

[0027] (4) Pass the obtained solution through a syringe to spray the spinning solution from the spinneret, and collect it on a collecting plate to obtain nanofibers.

[0028] Spinning process parameters: the AC voltage is 15kV, and the distance from the spinneret to the collecting plate is 20cm.

[0029] The parts by mass of each component are: 60 chitosan, 50 silk protein, 39 soybean protein, 40 polylactic acid, 25 nanometer titanium dioxide, 250 dimethylfor...

Embodiment 3

[0031] A method for preparing nanofibers, comprising the following steps,

[0032] (1) Coupling agent KH560 and nano-sized titanium dioxide are uniformly mixed at 65°C in the presence of a certain solvent dimethylformamide;

[0033] (2) Chitosan is added in the formic acid solution, stirred and mixed evenly at room temperature, then added silk protein, soybean protein solution, stirred evenly;

[0034] (3) Add polylactic acid to the solution of step (2), mix well, and then mix it with the solution of step (1) at 65°C;

[0035] (4) Pass the obtained solution through a syringe to spray the spinning solution from the spinneret, and collect it on a collecting plate to obtain nanofibers.

[0036] Spinning process parameters: the AC voltage is 20kV, and the distance from the spinneret to the collecting plate is 25cm.

[0037] The parts by mass of each component are: 55 chitosan, 45 silk protein, 36 soybean protein, 35 polylactic acid, 22 nanometer titanium dioxide, 300 dimethylfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com