Water-based non-stick bactericidal environment-friendly coating and preparation method thereof

An environmentally friendly paint, water-based technology, applied in anti-fouling/underwater paint, polyether paint, coating and other directions, can solve the problems of no strong sterilization, inconvenient construction, high energy consumption, etc., to achieve a significant sterilization effect, The effect of fast forming speed and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

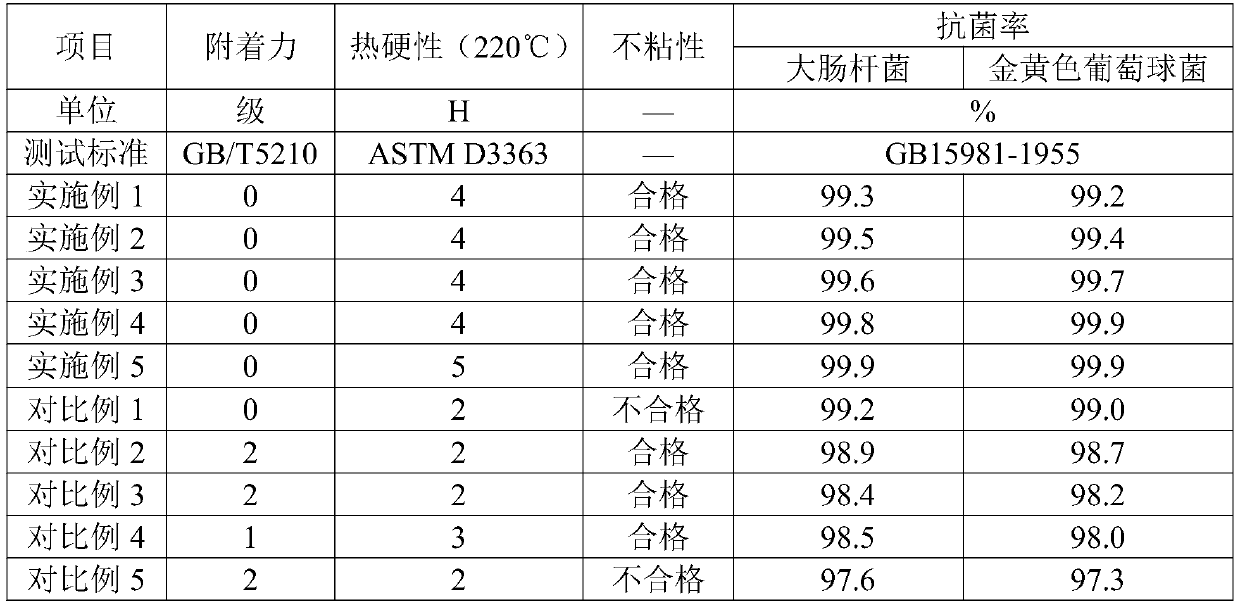

Examples

Embodiment 1

[0029]A water-based non-stick bactericidal environmental protection coating is made of the following raw materials in parts by weight: antibacterial 3,5-diamino-1H-pyrazole-4-carboxylic acid allyl ester / 1,4-bis(2',3 30 parts of '-epoxypropyl) perfluorobutane polycondensate, 1 part of [(3,3,3-trifluoro-1-propenyl)thio]benzene, 1,3-diallyl-2- 1 part of thiourea, 1 part of stilbene glycoside, 0.5 part of zinc pyridonic acid, 10 parts of polyethylene glycol diacrylate, 10 parts of titanium dioxide, 1 part of glycerin, 15 parts of water, 0.5 part of benzoin ethyl ether, dodecane 2 parts of sodium phenyl sulfonate, 1 part of monoglyceride stearate, 1 part of polydimethylsiloxane, and 1 part of perfluoroalkyl sulfonate.

[0030] The preparation method of the antibacterial 3,5-diamino-1H-pyrazole-4-carboxylic acid allyl ester / 1,4-bis(2',3'-epoxypropyl) perfluorobutane polycondensate, Including the following steps:

[0031] Step S1, 100 g of allyl 3,5-diamino-1H-pyrazole-4-carboxylat...

Embodiment 2

[0035] A water-based non-stick bactericidal environmental protection coating is made of the following raw materials in parts by weight: antibacterial 3,5-diamino-1H-pyrazole-4-carboxylic acid allyl ester / 1,4-bis(2',3 32 parts of '-epoxypropyl) perfluorobutane polycondensate, 1.2 parts of [(3,3,3-trifluoro-1-propenyl)thio]benzene, 1,3-diallyl-2- 1.5 parts of thiourea, 1.5 parts of stilbene glucoside, 0.7 parts of zinc pyridone, 11 parts of polyethylene glycol diacrylate, 12 parts of talcum powder, 2 parts of pentaerythritol, 17 parts of water, 0.7 parts of benzoin isopropyl ether, poly 3 parts of oxypropylene polyoxyethylene glyceryl ether, 1.3 parts of polyethylene wax, 1.5 parts of alkyl modified organosiloxane, and 1.5 parts of alkyl aryl polyether.

[0036] The preparation method of the antibacterial 3,5-diamino-1H-pyrazole-4-carboxylic acid allyl ester / 1,4-bis(2',3'-epoxypropyl) perfluorobutane polycondensate, Including the following steps:

[0037] Step S1, 100g of ally...

Embodiment 3

[0041] A water-based non-stick bactericidal environmental protection coating is made of the following raw materials in parts by weight: antibacterial 3,5-diamino-1H-pyrazole-4-carboxylic acid allyl ester / 1,4-bis(2',3 35 parts of '-epoxypropyl) perfluorobutane polycondensate, 1.5 parts of [(3,3,3-trifluoro-1-propenyl)thio]benzene, 1,3-diallyl-2- 2 parts of thiourea, 2 parts of stilbene glycoside, 1 part of zinc pyridone, 13 parts of polyethylene glycol diacrylate, 13 parts of montmorillonite, 3 parts of butyl acetate, 20 parts of water, 2,4-di 1 part of hydroxybenzophenone, 3.5 parts of nonylphenol polyoxyethylene ether, 1.5 parts of glyceryl tristearate, 2 parts of polyether polyester modified organosiloxane, and 2 parts of sodium octyl succinate sulfonate.

[0042] The preparation method of the antibacterial 3,5-diamino-1H-pyrazole-4-carboxylic acid allyl ester / 1,4-bis(2',3'-epoxypropyl) perfluorobutane polycondensate, Including the following steps:

[0043] Step S1, 100 g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com