Method for producing antimicrobial calcium alginate fiber

A technology of calcium alginate fiber and manufacturing method, which is applied in the direction of alginate artificial filament, fiber chemical characteristics, wet spinning method, etc., which can solve the problems of unable to keep the wound moist, damage tissue, limit the promotion and use of calcium alginate fiber, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

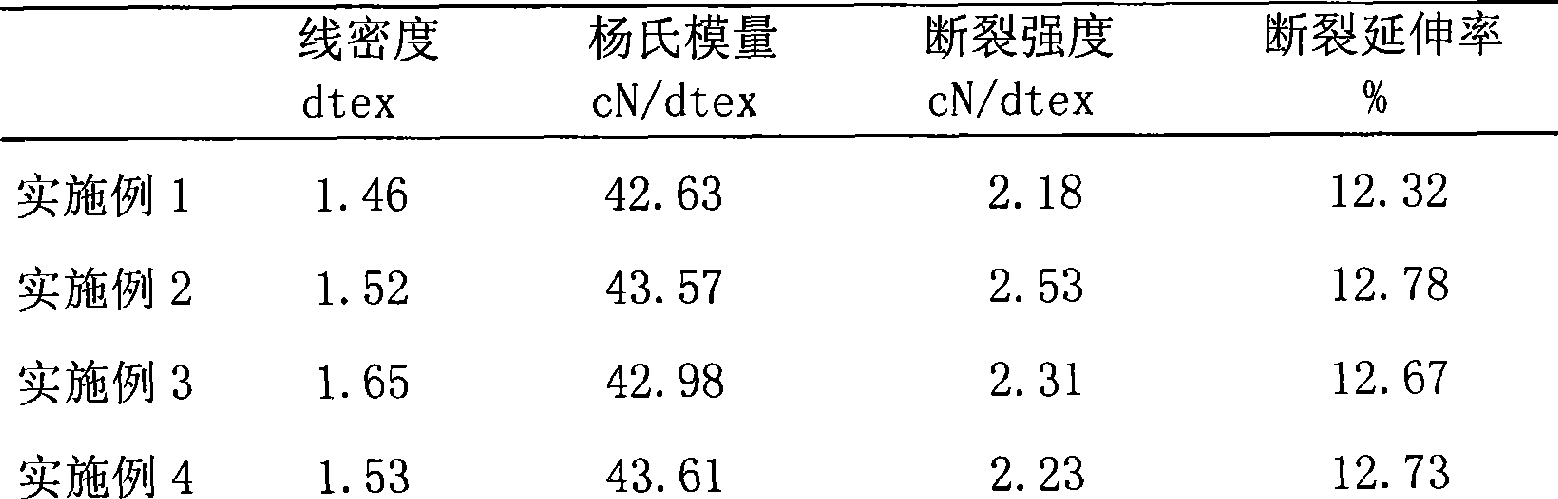

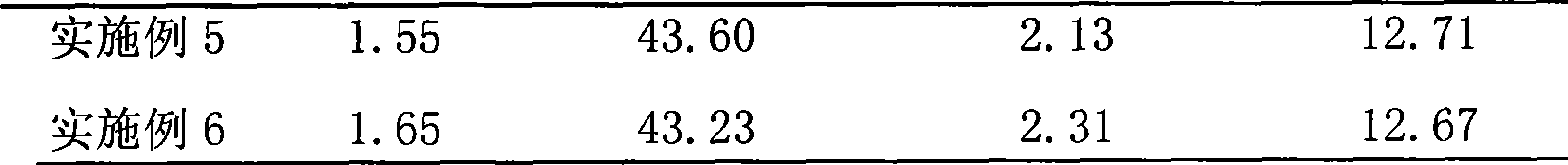

Examples

Embodiment 1

[0021] Dissolve 30 grams of sodium alginate in 970 mL of distilled water, stir mechanically for 3 or 3.5 hours to obtain a sodium alginate solution with a concentration of 3% by mass, filter and degas under reduced pressure for 15, 18 or 20 hours to obtain a spinning stock solution, and spin The temperature of silk stock solution is 15, 20 or 30 ℃; The preparation mass percent concentration is the calcium chloride aqueous solution of 4%, then adds a certain amount of dodecyl dimethyl benzyl ammonium chloride (cation surfactant 1227), The mass percentage concentration is 2%, and this blend solution is a coagulation bath for fibers; under pressure, the above-mentioned spinning stock solution enters the above-mentioned coagulation bath through a metering pump and a spinneret, and adopts a wet spinning process. Stretching, washing, and drying to obtain antibacterial calcium alginate fibers; in the above steps, the temperature of the coagulation bath is 15°C, 20 or 25°C, and the dra...

Embodiment 2

[0023] Dissolve 40 grams of sodium alginate in 960 mL of distilled water, stir mechanically for 3.5 or 4 hours to obtain a sodium alginate solution with a concentration of 4% by mass, filter and statically defoam for 20, 24, 26 or 30 hours to obtain a spinning stock solution, spin The temperature of the silk stock solution is 30, 35 or 40°C; prepare an aqueous solution of calcium chloride with a mass percent concentration of 5%, and then add a certain amount of alkyl dimethyl benzyl ammonium chloride to make the mass percent concentration 1%, This blending solution is a coagulation bath for fibers; under pressure, the above-mentioned spinning stock solution enters the above-mentioned coagulation bath through a metering pump and a spinneret, and adopts a wet spinning process to obtain antibacterial seaweed after drawing, washing and drying Calcium acid fiber; in the above steps, the temperature of the coagulation bath is 25, 30 or 35°C, the drafting adopts a three-stage drawing ...

Embodiment 3

[0025] Dissolve 50 grams of sodium alginate in 950 mL of distilled water, stir mechanically for 4.5 or 5 hours to obtain a sodium alginate solution with a mass percentage concentration of 5%, and obtain a spinning stock solution after filtering and static defoaming for 26 or 30 hours. The temperature of the spinning stock solution 40, 45 or 50°C; prepare an aqueous solution of calcium chloride with a mass percent concentration of 6%, and then add a certain amount of chlorhexidine to make the mass percent concentration 1.5%. This blended solution is the coagulation of the fiber bath; under pressure, the above-mentioned spinning stock solution enters the above-mentioned coagulation bath through a metering pump and a spinneret, and adopts a wet spinning process to obtain antibacterial calcium alginate fibers after being drawn, washed, and dried; in the above steps, The temperature of the coagulation bath is 35 or 40°C, the drawing adopts a three-stage drawing process, and the draf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com