Antibacterial food packaging film and processing technology thereof

A food packaging film, antibacterial technology, applied in the field of antibacterial food packaging film and its processing technology, can solve the problems of poor preservation effect, weak antibacterial performance of chitosan, etc. Reduce the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

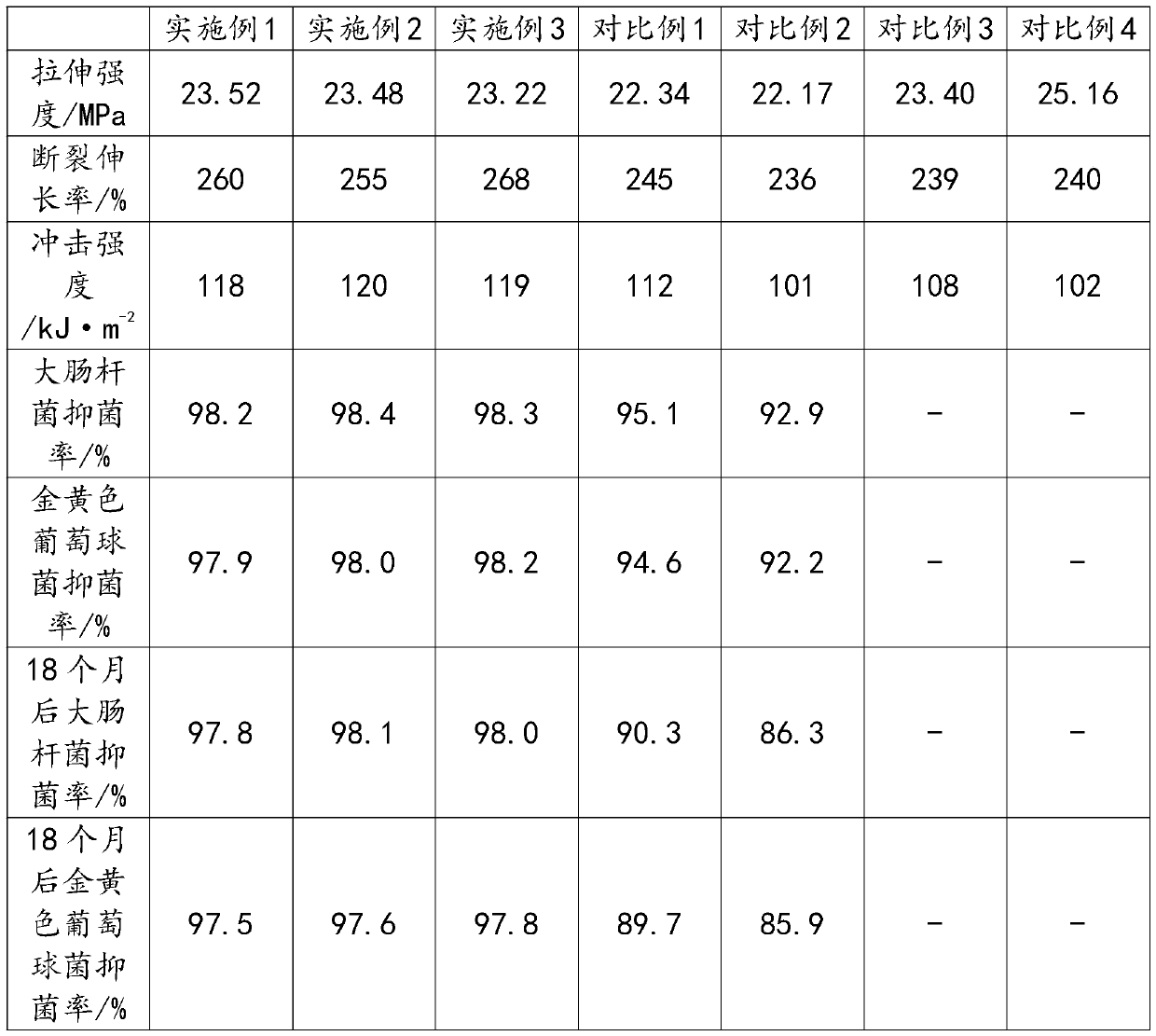

Examples

Embodiment 1

[0046] An antibacterial food packaging film is made of the following raw materials in parts by weight: 60-70 parts of modified polypropylene, 2-3 parts of antibacterial agent, 1.8-2 parts of zinc stearate, and 10100.5-0.7 parts of antioxidant;

[0047] The food packaging film is made by the following steps:

[0048] The first step is to mix 10% by weight of modified polypropylene, antibacterial agent, zinc stearate and antioxidant in a high-speed mixer, then extrude through a twin-screw extruder at 170 ° C, and cut into pellets. Granules made of plastic masterbatch;

[0049] In the second step, the plastic masterbatch and the remaining modified polypropylene are added to the hopper of the extruder at 185° C. through the screw, the die head, the cooling roller, and the winding mechanism to form a film to obtain the packaging film.

Embodiment 2

[0051] An antibacterial food packaging film is made of the following raw materials in parts by weight: 60-70 parts of modified polypropylene, 2-3 parts of antibacterial agent, 1.8-2 parts of zinc stearate, and 70-20.5-0.7 parts of antioxidant;

[0052] The food packaging film is made by the following steps:

[0053] The first step is to mix 10% by weight of modified polypropylene, antibacterial agent, zinc stearate and antioxidant in a high-speed mixer, then extrude through a twin-screw extruder at 170 ° C, and cut into pellets. Granules made of plastic masterbatch;

[0054] In the second step, the plastic masterbatch and the remaining modified polypropylene are added to the hopper of the extruder at 185° C. through the screw, the die head, the cooling roller, and the winding mechanism to form a film to obtain the packaging film.

Embodiment 3

[0056] An antibacterial food packaging film is made of the following raw materials in parts by weight: 60-70 parts of modified polypropylene, 2-3 parts of antibacterial agent, 1.8-2 parts of zinc stearate, and 10100.5-0.7 parts of antioxidant;

[0057] The food packaging film is made by the following steps:

[0058] The first step is to mix 10% by weight of modified polypropylene, antibacterial agent, zinc stearate and antioxidant in a high-speed mixer, then extrude through a twin-screw extruder at 170 ° C, and cut into pellets. Granules made of plastic masterbatch;

[0059] In the second step, the plastic masterbatch and the remaining modified polypropylene are added to the hopper of the extruder at 185° C. through the screw, the die head, the cooling roller, and the winding mechanism to form a film to obtain the packaging film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com